This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

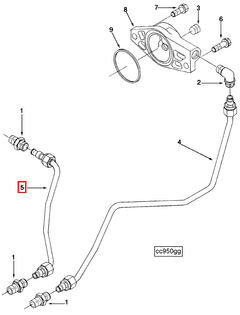

The 3354931 Compressor Water Outlet Tube is a component designed by Cummins for use in the cooling systems of heavy-duty trucks. Its purpose is to facilitate the efficient transfer of coolant from the compressor to other parts of the cooling system, thereby playing a role in maintaining optimal engine temperature 1.

Basic Concepts of Compressor Water Outlet Tube

The Compressor Water Outlet Tube operates on the fundamental principle of fluid dynamics within the engine cooling system. It is designed to direct the flow of coolant, which absorbs heat from the engine, away from the compressor and towards the radiator or other cooling components. This process aids in dissipating heat, which is vital for maintaining engine efficiency and preventing overheating 2.

Purpose and Function

This Cummins part is integral to the operation of a truck’s engine cooling system. It specifically facilitates the flow of coolant from the compressor, ensuring that the coolant circulates effectively through the system. This circulation is crucial for dissipating heat generated by the engine, thus helping to maintain a stable operating temperature 3.

Key Features

The Compressor Water Outlet Tube is constructed with durability and performance in mind. It is made from high-quality materials that resist corrosion and wear, ensuring longevity in demanding operating conditions. The tube features secure connection types that ensure a leak-free seal, and its design is optimized for efficient coolant flow 4.

Benefits

Using the 3354931 offers several advantages. It enhances coolant flow within the system, which contributes to better heat management. This improved heat management protects the engine from overheating, potentially extending its lifespan. Additionally, the tube’s robust construction increases the reliability of the cooling system under various operating conditions 5.

Installation and Compatibility

Proper installation of the Compressor Water Outlet Tube is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure secure connections and optimal performance. Compatibility with specific engine models and systems should be verified to ensure proper fit and function 6.

Troubleshooting and Maintenance

Common issues with Compressor Water Outlet Tubes may include leaks or blockages, which can impede coolant flow. Regular inspection and maintenance can help identify and address these issues promptly. Ensuring the tube and its connections are free from debris and corrosion will contribute to its efficient operation and longevity 7.

Performance and Efficiency

The Compressor Water Outlet Tube contributes to the overall performance and efficiency of the truck’s engine cooling system. By ensuring efficient coolant circulation, it plays a role in maintaining engine temperature within optimal ranges, which can enhance engine longevity and operational reliability 8.

Cummins Overview

Cummins Inc. is a leading manufacturer in the heavy-duty truck industry, known for its commitment to quality and innovation in automotive components. With a diverse product range, Cummins has established a reputation for producing reliable and high-performance parts, including the 3354931 Compressor Water Outlet Tube 9.

Role of Part 3354931 Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube, identified by part number 3354931, is a critical component in the efficient operation of engine systems that utilize compressor coolant. This tube is integral to the plumbing system, facilitating the controlled flow of coolant from the compressor to other parts of the engine.

In the context of the engine’s plumbing, the Compressor Water Outlet Tube ensures that coolant is effectively distributed. This distribution is vital for maintaining optimal temperatures within the engine, particularly around the compressor. The tube connects to the compressor coolant system, allowing for the precise channeling of coolant to areas where heat management is necessary.

The interaction between the Compressor Water Outlet Tube and the compressor coolant system is designed to enhance the engine’s performance and longevity. By ensuring a steady flow of coolant, the tube helps in dissipating heat generated during compression, thereby preventing overheating and potential damage to the compressor and other engine components 10.

Conclusion

In summary, the Compressor Water Outlet Tube plays a significant role in the engine’s plumbing and coolant system, contributing to the overall efficiency and reliability of the engine. Its proper installation, maintenance, and compatibility with specific engine models are crucial for optimal performance and longevity of the engine cooling system.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358393.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358393.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358393.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.