This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

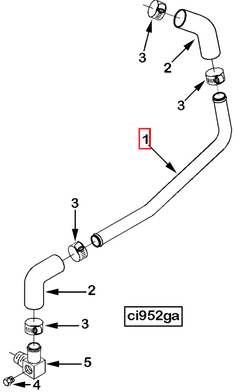

The Compressor Air Inlet Tube, identified by Part #3356280, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its heavy-duty truck components. This tube is integral to the air intake system of heavy-duty trucks, facilitating the efficient operation of the compressor.

Function and Operation

The Compressor Air Inlet Tube operates within the truck’s air system by directing ambient air into the compressor. This process is fundamental to the air compression system, as it ensures a steady and unobstructed flow of air necessary for the compressor’s function. The tube is designed to withstand the pressures and temperatures associated with the air intake process, ensuring reliable performance under various operating conditions 1.

Purpose of the Compressor Air Inlet Tube

The primary role of the Compressor Air Inlet Tube in a truck’s operation is to facilitate the air intake process. It acts as a conduit for air to travel from the outside environment into the compressor, where it is pressurized. This pressurized air is then used in various systems throughout the truck, including the brake system and pneumatic controls 2.

Key Features

The Compressor Air Inlet Tube is characterized by several key features that enhance its performance and durability. It is typically made from high-quality materials resistant to corrosion and wear, ensuring longevity. The design of the tube includes features that reduce turbulence and improve airflow efficiency, contributing to the overall effectiveness of the air compression system.

Benefits

The advantages provided by the Compressor Air Inlet Tube include improved airflow, which enhances the efficiency of the air compression system. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. Additionally, the design of the tube contributes to the system’s overall efficiency, potentially leading to improved fuel economy and reduced maintenance costs.

Installation Process

Installing the Compressor Air Inlet Tube requires careful attention to detail to ensure proper function and longevity. The process involves securing the tube in place within the air intake system, ensuring all connections are tight and secure. It is important to follow manufacturer guidelines to avoid damage to the tube or surrounding components.

Common Issues and Troubleshooting

Typical problems associated with the Compressor Air Inlet Tube may include blockages, leaks, or damage to the tube itself. Troubleshooting these issues involves inspecting the tube for signs of wear or damage, checking connections for leaks, and ensuring the tube is free from obstructions. Addressing these issues promptly can prevent more significant problems within the air compression system.

Maintenance Tips

Regular maintenance of the Compressor Air Inlet Tube is crucial for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the tube to remove any debris that may obstruct airflow, and ensuring all connections are secure. Adhering to these maintenance practices can help prevent unexpected failures and ensure the efficient operation of the air compression system.

Cummins Overview

Cummins, the manufacturer of the Compressor Air Inlet Tube, has a rich history in the automotive industry, particularly in the production of heavy-duty truck components. Known for its commitment to quality and innovation, Cummins offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. The company’s reputation for reliability and performance makes its components, including the Compressor Air Inlet Tube, a preferred choice for many in the industry.

Cummins Compressor Air Inlet Tube 3356280

The Cummins Compressor Air Inlet Tube part number 3356280 is a critical component in the air intake system of various Cummins engines. This part is designed to ensure that the air entering the engine’s compressor is clean and free from contaminants, which is essential for maintaining optimal engine performance and efficiency.

Compatibility with Cummins Engines

The Compressor Air Inlet Tube 3356280 is specifically engineered to fit the following Cummins engine models:

- 4B3.9

- 4BT3.9

- 6BT5.9

These engines are widely used in various applications, including industrial, marine, and agricultural sectors. The part’s design ensures a seamless fit and reliable performance across these engine models, contributing to the overall durability and efficiency of the engine’s air intake system.

Importance in Engine Performance

The Compressor Air Inlet Tube plays a vital role in the engine’s air intake process. It directs the air from the engine’s surroundings into the compressor, where it is compressed and mixed with fuel before ignition. A well-functioning air inlet tube helps to:

- Enhance Airflow: Ensures that the air entering the compressor is unobstructed, which helps in achieving the desired compression ratio.

- Prevent Contamination: Filters out dust, debris, and other contaminants that could potentially damage the engine components.

- Improve Efficiency: Contributes to the overall efficiency of the engine by ensuring that the air-fuel mixture is optimal for combustion.

By maintaining the integrity and functionality of the air inlet tube, engine owners can expect better performance, longevity, and reliability from their Cummins engines.

Understanding the Role of Part 3356280 Compressor Air Inlet Tube in Engine Systems

The part 3356280 Compressor Air Inlet Tube is an essential component in the arrangement of various engine systems, particularly those involving compressors. Its primary function is to direct and regulate the flow of air into the compressor, ensuring optimal performance and efficiency.

Integration with Compressor Systems

In compressor-based engine systems, the 3356280 Compressor Air Inlet Tube is strategically positioned to channel air from the external environment directly into the compressor. This precise air delivery is vital for maintaining the compressor’s operational integrity. The tube’s design allows for a smooth and uninterrupted airflow, which is necessary for the compressor to function effectively.

Enhancing Airflow Efficiency

The arrangement of the 3356280 Compressor Air Inlet Tube within the engine system is designed to minimize turbulence and maximize airflow efficiency. By providing a direct and unobstructed path for air to enter the compressor, the tube helps in reducing energy losses and improving the overall performance of the engine. This efficient airflow is particularly important in high-performance engines where even minor improvements can lead to significant gains in power and efficiency.

Supporting System Reliability

The reliable operation of the 3356280 Compressor Air Inlet Tube is integral to the durability and longevity of the engine system. By ensuring a consistent and clean supply of air to the compressor, the tube helps prevent issues such as overheating and component wear. This reliability is essential for maintaining the engine’s performance over time and reducing the need for frequent maintenance.

Facilitating Maintenance and Upgrades

The design of the 3356280 Compressor Air Inlet Tube also considers ease of maintenance and potential upgrades. Its placement and construction allow for straightforward access during routine checks and replacements, which is beneficial for maintaining the engine’s overall health. Additionally, the tube’s compatibility with various compressor models makes it a versatile component for engine upgrades and modifications.

Conclusion

In summary, the 3356280 Compressor Air Inlet Tube plays a significant role in the efficient and reliable operation of compressor-based engine systems. Its precise integration within the engine arrangement ensures optimal airflow, supports system reliability, and facilitates maintenance and upgrades.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.