The U.S. Department of Transportation (USDOT) requires ground-only shipment of Hazardous Materials due to air shipment restrictions and regulations. Accordingly, this HAZMAT item can only be shipped by ground and cannot be shipped to Alaska, Hawaii, Puerto Rico, Guam or APO/FPO addresses. By purchasing this truck part, your order will be shipped ground-only.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

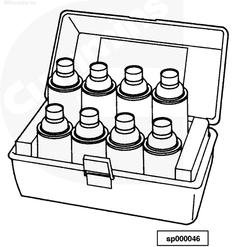

The Cummins 3375432 Crack Detection Kit is a specialized tool designed to aid in the maintenance and safety of commercial trucks. Its purpose is to facilitate the early detection of cracks in critical mechanical components, thereby helping to prevent potential failures and enhance the overall reliability of the vehicle.

Basic Concepts of Crack Detection

Crack detection in mechanical components involves identifying small fractures that may not be visible to the naked eye. This process is essential for maintaining the integrity and safety of machinery 1. Common methods and technologies used in crack detection include visual inspection, dye penetrant testing, magnetic particle testing, and ultrasonic testing. Each method has its own set of advantages and is chosen based on the specific requirements of the inspection.

Purpose of the Cummins 3375432 Crack Detection Kit

The Cummins 3375432 Crack Detection Kit is designed to identify potential cracks in critical components of commercial trucks. By enabling early detection, it plays a role in preventing catastrophic failures, ensuring the safety of the vehicle and its occupants, and maintaining the reliability of the truck’s operation.

Key Features

The Cummins 3375432 Crack Detection Kit includes several key features that enhance its effectiveness. These features include a robust design tailored for the demanding conditions of commercial trucking, components specifically chosen for their reliability and ease of use, and technological advancements that improve the accuracy and efficiency of crack detection.

Benefits of Using the Cummins 3375432 Crack Detection Kit

Utilizing the Cummins 3375432 Crack Detection Kit offers several advantages. It contributes to improved safety by identifying potential issues before they become critical. It enhances the reliability of the truck by ensuring that components are in good condition. Additionally, early detection of cracks can lead to potential cost savings by preventing more extensive damage and reducing downtime.

Operation and Usage

To use the Cummins 3375432 Crack Detection Kit, begin by preparing the component to be inspected. This may involve cleaning the surface to remove any dirt or debris. Apply the detection solution according to the kit’s instructions, allowing it to penetrate any cracks present. After a specified dwell time, wipe off the excess solution and observe the area under appropriate lighting conditions. Cracks will be indicated by the presence of the detection solution, which can then be interpreted based on the kit’s guidelines.

Troubleshooting Common Issues

Users may encounter several common issues when using the Cummins 3375432 Crack Detection Kit, such as false positives or difficulty in interpreting results. To address these issues, ensure that the component is thoroughly cleaned before application, follow the dwell time precisely, and use the correct lighting conditions for observation. If problems persist, consult the kit’s instruction manual or contact technical support for further assistance.

Maintenance and Care

To ensure the longevity and effectiveness of the Cummins 3375432 Crack Detection Kit, follow recommended maintenance and care practices. Store the kit in a cool, dry place away from direct sunlight. Periodically check the condition of the components and solutions, replacing any that have expired or become contaminated. Regular maintenance will help to ensure that the kit remains in optimal working condition.

Integration with Fleet Management

The Cummins 3375432 Crack Detection Kit can be integrated into fleet management practices to improve overall vehicle maintenance and safety protocols. By incorporating regular crack detection inspections into the maintenance schedule, fleet managers can identify and address potential issues before they lead to vehicle downtime or safety incidents. This proactive approach can lead to more efficient fleet operations and enhanced safety standards.

Case Studies and Real-World Applications

The Cummins 3375432 Crack Detection Kit has been successfully used in various commercial trucking scenarios. For example, a fleet operator reported that regular use of the kit helped to identify cracks in critical components before they led to failures, resulting in reduced maintenance costs and improved vehicle reliability. Another case involved a trucking company that integrated the kit into its maintenance protocol, leading to fewer unexpected breakdowns and increased driver confidence in vehicle safety.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins plays a significant role in the commercial trucking industry. The development of the 3375432 Crack Detection Kit reflects Cummins’ dedication to enhancing the safety, reliability, and efficiency of commercial vehicles.

Conclusion

The Cummins 3375432 Crack Detection Kit is an invaluable tool for the maintenance and safety of commercial trucks. By facilitating the early detection of cracks in critical components, it helps prevent potential failures, enhances vehicle reliability, and contributes to overall safety. Its integration into fleet management practices can lead to more efficient operations and improved safety standards. The kit’s robust design, ease of use, and technological advancements make it a reliable choice for commercial trucking applications.

-

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.