This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3376009 Special Install Bolt is a specialized component designed for use in heavy-duty truck maintenance and operation. This bolt is integral to ensuring the structural integrity and performance of trucks, particularly those equipped with Cummins engines. Understanding its purpose and significance can help technicians and fleet managers maintain their vehicles more effectively 1.

Purpose and Function

The 3376009 Special Install Bolt plays a role in truck assembly and maintenance by securing critical components in place. It is designed to withstand the high stresses and vibrations encountered in heavy-duty applications, thereby contributing to the overall durability and reliability of the truck. By ensuring that components are firmly attached, this bolt helps maintain the structural integrity of the vehicle, which is vital for safe and efficient operation 2.

Key Features

The Cummins 3376009 Special Install Bolt is engineered with specific design and material specifications to meet the demanding requirements of heavy-duty trucks. It is typically made from high-strength steel, which provides superior durability and resistance to wear and tear. Unique characteristics of this bolt may include a specialized thread pattern or coating that enhances its performance under extreme conditions. These features differentiate it from standard bolts, making it more suitable for heavy-duty applications 3.

Benefits

Using the Cummins 3376009 Special Install Bolt offers several advantages. Its high-strength material ensures durability, reducing the likelihood of failure under stress. The bolt’s design also contributes to resistance against wear and tear, extending its service life. Additionally, the ease of installation, thanks to its specialized features, allows for quicker and more efficient maintenance procedures, minimizing downtime for fleet operations 4.

Installation Process

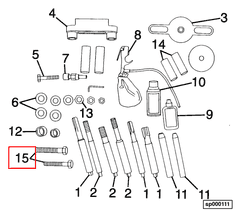

Proper installation of the Cummins 3376009 Special Install Bolt is crucial for ensuring its effectiveness. The installation process involves several steps:

- Identify the correct location for the bolt on the truck.

- Use the appropriate torque wrench to install the bolt to the specified torque settings.

- Ensure that all mating surfaces are clean and free of debris to prevent corrosion.

- Verify that the bolt is securely fastened and that there is no excessive play or movement.

Tools required may include a torque wrench, socket set, and cleaning supplies. Following these steps ensures that the bolt is installed correctly and functions as intended .

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3376009 Special Install Bolt is important for ensuring its longevity and performance. This includes periodic inspections for signs of wear, corrosion, or loosening. If any issues are detected, such as rust or reduced torque, the bolt should be addressed promptly to prevent further damage. Troubleshooting may involve re-torquing the bolt, cleaning the installation area, or replacing the bolt if it is damaged .

Safety Considerations

When installing or maintaining the Cummins 3376009 Special Install Bolt, it is important to follow safety guidelines to prevent accidents and ensure effective performance. This includes wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses. Additionally, ensure that the truck is securely supported on a level surface before beginning any work. Be aware of the potential risks associated with high torque applications, and take steps to mitigate them, such as using the correct tools and following torque specifications .

Conclusion

The Cummins 3376009 Special Install Bolt is a critical component in the maintenance and operation of heavy-duty trucks. Its high-strength design, specialized features, and ease of installation contribute to the durability, reliability, and efficiency of truck operations. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the performance and longevity of this Cummins part.

References

-

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ -

Robert Huzij, Angelo Spano, Sean Bennett, Modern Diesel Technology: Heavy Equipment Systems, Cengage Learning, 2019.

↩ -

Richard Viskup, Diesel and Gasoline Engines, IntechOpen, 2020.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4383641, B6.7 G CMOH6.0 B125.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.