This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

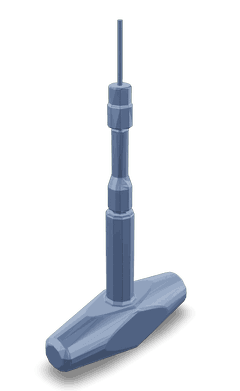

The Cummins 3376177 Torque Wrench is a specialized tool designed for the maintenance and operation of commercial trucks. It ensures that components are fastened to the manufacturer’s specified torque settings, which is vital for the safety, performance, and longevity of the vehicle 1.

Basic Concepts of a Torque Wrench

A torque wrench is a tool used to apply a specific amount of torque to a fastener, such as a nut or bolt. It operates by allowing the user to set a desired torque level, which the wrench then applies to the fastener. This precision is important in fastening operations to prevent under-tightening, which can lead to loose components, or over-tightening, which can cause damage to the fastener or the component it is securing 2.

Purpose of the Cummins 3376177 Torque Wrench

The Cummins 3376177 Torque Wrench is specifically designed for use in the maintenance and repair of commercial trucks. It plays a role in ensuring that engine components and other critical parts are fastened to the precise torque specifications recommended by Cummins. This accuracy is important for maintaining the integrity and performance of the truck’s engine and other systems 3.

Key Features

The Cummins 3376177 Torque Wrench is characterized by several key features that enhance its performance and reliability. These include a robust design that can withstand the rigors of commercial truck maintenance, the use of high-quality materials that ensure durability, and unique characteristics such as an ergonomic handle for user comfort and precision during operation.

Benefits of Using the Cummins 3376177 Torque Wrench

Using this Cummins part offers several advantages. It provides improved accuracy in torque application, which is important for the proper functioning and safety of commercial trucks. Its durable construction contributes to enhanced longevity, reducing the need for frequent replacements. Additionally, the precise torque application can lead to potential cost savings by minimizing maintenance and repair needs due to improperly fastened components 4.

Applications in Truck Maintenance

The Cummins 3376177 Torque Wrench finds applications in various aspects of truck maintenance. It is used in engine assembly to ensure that components are fastened to the correct torque specifications. During component replacement, it helps in securing new parts with the precision required for optimal performance. It also plays a role in routine inspections, where it is used to verify that fasteners are tightened to the manufacturer’s specifications.

Troubleshooting Common Issues

When using the Cummins 3376177 Torque Wrench, it is important to be aware of common issues that may arise. These can include calibration errors, which may require recalibration of the tool, wear and tear on the wrench that could affect its accuracy, and user mistakes such as incorrect torque settings or improper use of the tool. Addressing these issues promptly can help maintain the tool’s accuracy and reliability.

Maintenance and Care

To ensure the longevity and accurate performance of the Cummins 3376177 Torque Wrench, proper maintenance and care are important. This includes regular cleaning to remove dirt and debris that could affect its operation, storing the tool in a safe place to prevent damage, and conducting periodic calibration checks to ensure it continues to apply torque accurately.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial vehicles, underscoring Cummins’ dedication to excellence and customer satisfaction.

Conclusion

The Cummins 3376177 Torque Wrench is an essential tool for the maintenance and repair of commercial trucks, ensuring that components are fastened to the precise torque specifications recommended by Cummins. Its robust design, durable construction, and precise torque application contribute to the safety, performance, and longevity of commercial trucks. Proper maintenance and care of this tool are important to ensure its accurate performance and longevity.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Zhan, Quansheng, Eben, Shengbo, Deng, Li Kun. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Hiereth, Hermann, Prenninger, Peter, Drexl, Klaus W. Charging the Internal Combustion Engine. Springer, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.