This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

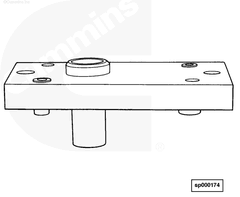

The 3376903 Reaming Fixture, manufactured by Cummins, is a specialized tool designed for the maintenance and repair of commercial trucks. Cummins, a well-established name in the automotive industry, ensures that this fixture meets the high standards required for precision machining and engine repair tasks. The fixture’s role in maintaining the integrity and performance of truck engines underscores its significance in the field of commercial vehicle maintenance 1.

Basic Concepts of Reaming Fixtures

Reaming fixtures are tools used in machining processes to hold and guide a cutting tool as it enlarges a pre-drilled hole to a precise size and smooth finish. These fixtures ensure accuracy and consistency in the machining process, which is vital for the proper functioning of engine components. In engine repair, reaming fixtures are employed to restore worn or damaged holes to their original specifications, ensuring that parts fit correctly and operate efficiently 2.

Purpose of the 3376903 Reaming Fixture

This Cummins part is specifically designed to facilitate precision machining tasks in the maintenance and repair of trucks. It plays a role in ensuring that holes within engine components are machined to the exact dimensions required for optimal performance. This fixture is particularly useful in tasks where high precision is necessary, such as in the repair of cylinder liners or other critical engine parts 3.

Key Features

The 3376903 boasts several features that enhance its functionality. Its design incorporates durable materials that can withstand the rigors of machining processes. The fixture is engineered to provide stability and accuracy during operation, ensuring that the reaming process is performed with minimal deviation from the desired specifications. Additionally, it may include unique attributes such as adjustable components to accommodate various hole sizes and shapes, enhancing its versatility in different machining scenarios.

Benefits of Using the 3376903 Reaming Fixture

Utilizing this part offers several advantages in truck maintenance. It contributes to improved accuracy in machining tasks, which is crucial for the reliable operation of engine components. The fixture can also save time by streamlining the reaming process, allowing for quicker turnaround times in repairs. Furthermore, by ensuring precision and efficiency, it may lead to potential cost reductions in maintenance operations, as parts are less likely to require rework or replacement due to machining errors.

Installation and Usage Guidelines

To install and use the 3376903, follow these steps for optimal performance and safety:

- Secure the fixture to the machining table or workbench using the provided clamps or fasteners.

- Align the component to be machined with the fixture, ensuring it is properly positioned and supported.

- Insert the reaming tool into the fixture, making sure it is correctly aligned with the hole to be machined.

- Begin the machining process, monitoring the operation to ensure accuracy and smoothness.

- Upon completion, carefully remove the component and inspect the machined hole for quality and precision.

Troubleshooting Common Issues

Frequent problems with the 3376903 may include misalignment of the reaming tool, inaccuracies in the machined hole, or fixture instability during operation. To address these issues:

- Check the alignment of the fixture and the component being machined to ensure they are correctly positioned.

- Inspect the reaming tool for wear or damage, replacing it if necessary to maintain machining accuracy.

- Ensure the fixture is securely fastened to the work surface to prevent movement during operation.

Maintenance Tips

Regular maintenance of the 3376903 is crucial for its longevity and consistent performance. Recommendations include:

- Cleaning the fixture after each use to remove debris and machining residues.

- Inspecting for wear or damage, particularly on adjustable components, and replacing parts as needed.

- Lubricating moving parts to ensure smooth operation and prevent rust or corrosion.

Safety Considerations

When using the 3376903, observe the following safety practices:

- Wear appropriate personal protective equipment, including safety glasses and gloves, to protect against machining debris and tool movement.

- Ensure the fixture and machining area are clean and free of obstructions to prevent accidents.

- Follow all manufacturer guidelines for operation and maintenance to protect users and maintain equipment integrity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range and commitment to innovation ensure that its offerings, like the 3376903 Reaming Fixture, meet the high demands of professional truck maintenance and repair.

Conclusion

The 3376903 Reaming Fixture by Cummins is an indispensable tool in the maintenance and repair of commercial trucks, offering precision, efficiency, and reliability. Its design and features cater to the demanding requirements of engine repair, ensuring that truck engines operate at their best. Regular maintenance and proper usage of this fixture not only enhance the performance of truck engines but also contribute to the overall efficiency of maintenance operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.