This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

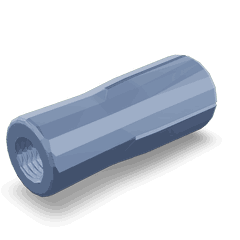

The Cummins 3376945 Remover Collet is a specialized tool designed for the maintenance and repair of commercial trucks. This component is integral to the efficient disassembly and assembly processes in truck maintenance. Cummins Inc., a renowned manufacturer in the commercial truck industry, produces this tool, leveraging its expertise and commitment to quality and innovation 1.

Basic Concepts of Remover Collet

A Remover Collet is a tool used to grip and hold cylindrical objects securely. It operates on the principle of applying radial pressure to create a firm hold, which is crucial for tasks such as removing or installing components in mechanical systems. In the context of truck maintenance, collets are employed in various applications to ensure precise and secure handling of parts 2.

Purpose of the 3376945 Remover Collet

The 3376945 Remover Collet is specifically designed to facilitate the removal and installation of components in commercial trucks. It is particularly useful in scenarios where a secure and precise grip is required to avoid damage to the components or the surrounding areas. Its application is vital in maintaining the integrity and efficiency of truck engines and other mechanical systems 3.

Key Features

The 3376945 Remover Collet boasts several key features that enhance its functionality. It is constructed from durable materials to withstand the rigors of commercial truck maintenance. Its design includes elements that allow for a secure and adjustable grip, catering to various sizes of cylindrical objects. Additionally, the collet is engineered for ease of use, ensuring that technicians can operate it efficiently during maintenance procedures.

Benefits of Using the 3376945 Remover Collet

Utilizing the 3376945 Remover Collet offers several advantages. Its efficient operation reduces the time required for maintenance tasks, contributing to overall productivity. The durability of the collet ensures long-term use, providing cost-effectiveness over alternative solutions. Moreover, its precise grip capability minimizes the risk of component damage during removal and installation processes.

Installation and Usage Guidelines

Proper installation and usage of the 3376945 Remover Collet involve several steps. Initially, ensure that the collet is compatible with the specific application. Follow the manufacturer’s instructions for attaching the collet to the appropriate tool. When in use, apply the collet to the cylindrical object with care, ensuring a secure fit before proceeding with the removal or installation process. Safety precautions include wearing appropriate personal protective equipment and ensuring the work area is clear of obstructions.

Troubleshooting Common Issues

Common issues with the 3376945 Remover Collet may include difficulty in achieving a secure grip or damage to the collet itself. To address these, first, ensure that the collet is correctly sized for the object in question. If grip issues persist, inspect the collet for any signs of wear or damage that may impair its function. Basic repairs or adjustments might involve cleaning the collet or replacing worn components.

Maintenance Tips

Regular maintenance of the 3376945 Remover Collet is crucial for its longevity and optimal performance. This includes routine cleaning to remove any debris or contaminants that may affect its grip. Inspect the collet regularly for signs of wear or damage, and replace it if necessary to maintain efficiency and safety in its operation. Adhering to these maintenance practices ensures the collet remains a reliable tool in truck maintenance.

Compatibility and Applications

The 3376945 Remover Collet is designed for use with specific types of trucks and engines, ensuring compatibility with the mechanical systems it is intended to service. It is also compatible with a range of tools and equipment, enhancing its versatility in various maintenance scenarios.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its extensive product range and commitment to quality. With a history of innovation and excellence, Cummins has established a reputation for producing reliable and high-performance components. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a trusted name in the industry.

Role of Part 3376945 Remover Collet in Engine Systems

The Part 3376945 Remover Collet is an essential component in the maintenance and repair of engine systems, particularly when dealing with the removal of dowel pins. This tool is designed to grip and extract dowel pins securely, ensuring that the process is both efficient and safe.

Functionality with Dowel Pin Remover

When integrated with a dowel pin remover, the Remover Collet plays a significant role in facilitating the extraction of dowel pins from engine components. Dowel pins are often used to align and secure parts within an engine, such as gears, bearings, and housings. Over time, these pins can become seized or corroded, making their removal a challenging task.

The Remover Collet, when used in conjunction with a dowel pin remover, provides a precise and controlled grip on the pin. This grip ensures that the pin is extracted without causing damage to surrounding components. The collet’s design allows for adjustments to fit various pin sizes, enhancing its versatility in different engine systems.

Benefits in Engine Maintenance

Incorporating the Remover Collet into engine maintenance routines offers several advantages. It minimizes the risk of component damage during pin removal, which can be particularly beneficial in high-precision engine systems where even minor damage can lead to significant performance issues. Additionally, the use of a Remover Collet can reduce the time required for pin extraction, improving overall efficiency in maintenance procedures.

The tool’s ability to provide a secure grip also enhances safety for the mechanic, reducing the likelihood of injuries that can occur when using less precise methods for pin removal. This is especially important in environments where engine systems are complex and require meticulous attention to detail.

Integration with Other Tools

Beyond its use with dowel pin removers, the Remover Collet can be integrated with various other tools and equipment within engine systems. Its compatibility with different extraction tools makes it a versatile addition to any mechanic’s toolkit. Whether used for routine maintenance or more complex repairs, the Remover Collet ensures that dowel pin extraction is performed with accuracy and reliability.

Conclusion

In summary, the Part 3376945 Remover Collet is a valuable component in the toolkit of any engineer or mechanic working with engine systems. Its role in facilitating the safe and efficient removal of dowel pins underscores its importance in maintaining the integrity and performance of engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.