This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3392504 Restriction Indicator is a component designed to monitor and signal potential issues within the systems of commercial trucks. Its purpose is to provide early warnings of restrictions or blockages that could affect the performance and efficiency of the truck. Understanding its function and significance is vital for maintaining the optimal operation of commercial vehicles 1.

Basic Concepts of Restriction Indicators

A restriction indicator is a device that monitors the flow of fluids or air within a system. It functions by detecting changes in pressure or flow rate that may indicate a restriction or blockage. This monitoring capability plays a role in maintaining the performance of truck systems by providing timely alerts to operators, allowing for proactive maintenance and reducing the risk of system failures 2.

Purpose of the Cummins 3392504 Restriction Indicator

The Cummins 3392504 Restriction Indicator is specifically designed to monitor the air intake system of trucks. It plays a role in detecting any restrictions in the air filter or intake tract that could impede the engine’s performance. By providing early warnings, it helps maintain the efficiency of the engine and ensures that the truck operates within its optimal parameters 3.

Key Features

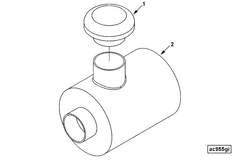

The Cummins 3392504 Restriction Indicator features a robust design that includes durable materials to withstand the harsh conditions of commercial truck environments. It incorporates a sensitive pressure sensor that accurately detects changes in air flow. Additionally, it is designed for easy integration into existing truck systems, with a straightforward installation process that minimizes downtime.

Benefits of Using the Cummins 3392504 Restriction Indicator

Utilizing the Cummins 3392504 Restriction Indicator offers several advantages. It contributes to improved system performance by ensuring that the engine receives an unrestricted air supply. Early detection of issues allows for timely maintenance, which can prevent more severe problems and extend the lifespan of the truck’s components. Moreover, it enhances safety by reducing the likelihood of unexpected failures during operation.

Installation and Integration

Proper installation of the Cummins 3392504 Restriction Indicator involves several steps. It begins with ensuring the truck’s system is compatible with the indicator. The installation process includes mounting the indicator in a location that allows for accurate monitoring of the air intake system. It is important to follow the manufacturer’s guidelines to ensure correct integration and functionality.

Operation and Monitoring

The Cummins 3392504 Restriction Indicator operates by continuously monitoring the air flow within the intake system. It provides visual or audible alerts when a restriction is detected. Regular monitoring of these alerts is important to address any issues promptly. Operators should familiarize themselves with the indicator’s signals and take appropriate action when warnings are issued.

Troubleshooting Common Issues

Common problems with the Cummins 3392504 Restriction Indicator may include false alarms or failure to detect restrictions. Troubleshooting steps involve checking the sensor for debris or damage, ensuring proper installation, and verifying that the indicator is correctly integrated into the truck’s system. Consulting the manufacturer’s troubleshooting guide can provide specific solutions to common issues.

Maintenance Tips

To keep the Cummins 3392504 Restriction Indicator in good working condition, regular maintenance is recommended. This includes cleaning the sensor to remove any accumulated dirt or debris, inspecting the indicator for signs of wear or damage, and following the manufacturer’s recommended replacement schedule. Adhering to these maintenance practices helps ensure the indicator’s reliability and accuracy.

Compatibility with Cummins Engines

G855 and N14 G Engines

The Restriction Indicator part 3392504 is specifically designed to fit seamlessly within the exhaust systems of the Cummins G855 and N14 G engines. These engines are known for their robust construction and are widely used in heavy-duty applications, including industrial, agricultural, and transportation sectors.

Installation and Functionality

When installed, the Restriction Indicator part 3392504 is positioned in such a way that it can accurately measure the exhaust backpressure. This measurement is crucial for maintaining the engine’s performance and ensuring that the exhaust system is functioning correctly. The part works by detecting changes in the exhaust flow and triggering an alert if a restriction is detected. This alert allows operators to take corrective action before the restriction leads to more severe issues.

Benefits of Using the Restriction Indicator

- Prevents Performance Degradation: By alerting operators to potential restrictions, the part helps maintain optimal engine performance.

- Reduces Downtime: Early detection of exhaust restrictions can prevent unexpected engine failures, thereby reducing downtime.

- Enhances Engine Longevity: By ensuring that the exhaust system is free from blockages, the part contributes to the overall longevity of the engine.

Maintenance and Installation

Proper installation and regular maintenance of the Restriction Indicator part 3392504 are essential to ensure its effectiveness. Operators should follow the manufacturer’s guidelines for installation and adhere to the recommended maintenance schedule to keep the part in optimal working condition.

Understanding the Role of Part 3392504 Restriction Indicator in Engine Systems

In the intricate network of an engine system, the Restriction Indicator (Part 3392504) serves a significant function by ensuring optimal performance and longevity of various components. This part is designed to monitor and signal any restrictions within the airflow pathways, which can have a cascading effect on the entire engine system.

When integrated with the Air Cleaner and Air Cleaner Kit, the Restriction Indicator provides real-time feedback on the condition of the air filtration system. Any buildup of contaminants or blockages within the Air Cleaner can impede airflow, leading to reduced engine efficiency and potential damage over time. The indicator alerts maintenance personnel to clean or replace the Air Cleaner before significant performance issues arise.

The Air Cleaner Mounting and Air Inlet Assembly are also closely tied to the functionality of the Restriction Indicator. Proper mounting and assembly ensure that the airflow path is unobstructed and that the indicator can accurately sense any changes in airflow resistance. If the Air Cleaner Mounting is loose or the Air Inlet Assembly is misaligned, the indicator may provide false readings, leading to unnecessary maintenance or overlooked issues.

In conjunction with the Cleaner, Air and Indicator, Restriction, the system maintains a balanced airflow that is essential for the efficient operation of the Module, Fuel Control. Restricted airflow can lead to an improper air-fuel mixture, which the Module, Fuel Control relies on to deliver the correct amount of fuel for combustion. This, in turn, affects engine performance and fuel efficiency.

The Mounting, Air Cleaner plays a supportive role by securing the air cleaner in place, ensuring that the Restriction Indicator can function correctly. Any instability in the mounting can lead to inaccurate readings from the indicator, compromising the system’s ability to maintain optimal airflow.

Lastly, the Plumbing, Air Cleaner ensures that the air pathways are correctly routed and free from obstructions. The Restriction Indicator relies on this plumbing to deliver consistent and accurate airflow data, allowing for timely interventions when restrictions are detected.

Conclusion

In summary, the Cummins 3392504 Restriction Indicator is an integral component that works in harmony with various engine system parts to maintain efficient airflow, ensure proper fuel delivery, and ultimately contribute to the overall performance and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.