This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

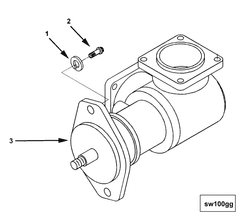

The Cummins 3393162 Impeller is a component designed for use in commercial trucks, playing a significant role in their operation. This part is integral to maintaining the efficiency and performance of the truck’s systems, particularly within the engine cooling mechanism.

Basic Concepts of an Impeller

An impeller is a rotor used to increase (or decrease in the case of a turbine) the pressure and flow of a fluid or gas. It consists of a central rotating hub with blades that spin to move the fluid. In various machinery, impellers are employed to facilitate fluid dynamics and propulsion. They are commonly found in pumps, compressors, and turbines, where they help to move fluids efficiently through systems 1.

Purpose of the 3393162 Impeller in Truck Operation

This Cummins part serves a specific function within the operation of a truck. It is primarily involved in the engine cooling system, where it helps circulate coolant through the engine and radiator. This circulation is vital for dissipating heat generated by the engine, thereby maintaining optimal operating temperatures and preventing overheating. Additionally, the impeller may play a role in other systems where fluid movement is necessary 2.

Key Features of the 3393162 Impeller

The design and construction of the 3393162 are tailored to enhance its performance and durability. It is made from materials that resist corrosion and wear, ensuring longevity in demanding environments. The blade design is optimized for efficient fluid movement, and the manufacturing processes employed ensure precision and reliability. These features collectively contribute to the impeller’s effectiveness in truck operations 3.

Benefits of Using the 3393162 Impeller

Utilizing this part in truck systems offers several advantages. It provides improved efficiency in fluid circulation, leading to better engine cooling and overall system performance. The reliability of the impeller ensures consistent operation, reducing the likelihood of system failures. Additionally, its design contributes to enhanced durability, making it a valuable component for commercial truck applications 4.

Installation and Integration

Proper installation and integration of the 3393162 are crucial for ensuring optimal performance and compatibility within truck systems. Guidelines for installation should be followed to avoid issues such as misalignment or improper sealing, which could affect the impeller’s efficiency and the system’s overall functionality. Compatibility with existing systems should also be considered to ensure seamless integration.

Troubleshooting Common Issues

Common problems associated with the 3393162 may include issues such as reduced efficiency, unusual noises, or leaks. Troubleshooting steps may involve inspecting the impeller for signs of wear or damage, checking the alignment and fit within the system, and ensuring that all connections are secure. Solutions may range from cleaning and realigning the impeller to replacing damaged components.

Maintenance Practices

To ensure the longevity and consistent performance of the 3393162, recommended maintenance practices should be followed. This includes regular inspection routines to check for wear or damage, cleaning procedures to remove any buildup that may affect performance, and replacement guidelines to address any significant issues. Adhering to these practices helps maintain the impeller’s efficiency and reliability over time.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications.

Conclusion

The Cummins 3393162 Impeller is a critical component in the operation of commercial trucks, particularly within the engine cooling system. Its design and features contribute to efficient fluid circulation, ensuring optimal engine performance and longevity. Proper installation, maintenance, and troubleshooting practices are essential for maximizing the benefits of this part in truck operations.

-

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Thompson, Rob. Automotive Maintenance: Light Repair. Cengage Learning, 2019.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.