3400718

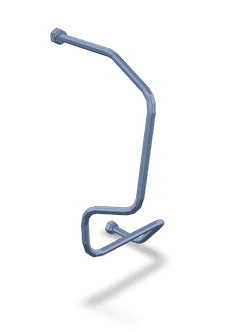

Compressor Water Outlet Tube

Cummins®

IN STOCK

6 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3400718 Compressor Water Outlet Tube is a component designed for use in heavy-duty trucks. It serves a specific function within the engine’s cooling system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and operation is key to maintaining the performance of heavy-duty trucks.

Basic Concepts and Functionality

The Compressor Water Outlet Tube operates on the fundamental principle of fluid dynamics within the engine’s cooling system. It facilitates the circulation of coolant from the compressor to other parts of the engine, ensuring that heat is effectively managed. This circulation is vital for dissipating the heat generated during engine operation, which if not properly managed, could lead to engine damage 1.

Purpose and Role in Truck Operation

Within the truck’s engine system, the 3400718 Compressor Water Outlet Tube directs coolant flow from the compressor to the engine’s cooling circuits. This function is integral to maintaining optimal engine temperature, which in turn supports consistent engine performance and prevents overheating. By ensuring that the engine operates within its designed temperature range, the tube contributes to the longevity and efficiency of the engine 2.

Key Features

The 3400718 Compressor Water Outlet Tube is characterized by its robust material composition and precise construction. These features are designed to withstand the high pressures and temperatures typical of heavy-duty truck engines. Its design includes specific attributes that enhance both its performance and durability, ensuring it can operate effectively under demanding conditions.

Benefits

The use of the 3400718 Compressor Water Outlet Tube offers several advantages. It contributes to improved engine efficiency by ensuring that coolant is effectively circulated throughout the engine. This efficient coolant flow reduces the risk of overheating and supports the enhanced longevity of engine components. The tube’s design and material also contribute to its reliability and performance under various operating conditions.

Installation and Compatibility

Proper installation of the 3400718 Compressor Water Outlet Tube is important for ensuring its effectiveness and compatibility with the truck’s engine system. Specific procedures and considerations should be followed to ensure that the tube is correctly fitted and functions as intended within the engine’s cooling system.

Maintenance and Troubleshooting

Routine maintenance practices are important for ensuring the optimal performance of the 3400718 Compressor Water Outlet Tube. Regular checks for leaks or blockages, and addressing any issues promptly, can help maintain the efficiency of the cooling system. Troubleshooting common issues such as leaks or blockages involves inspecting the tube and its connections, and making necessary repairs or replacements.

Performance and Reliability

The 3400718 Compressor Water Outlet Tube is designed to offer high performance and reliability. Its construction and material are chosen to withstand the rigors of heavy-duty truck operation, ensuring it can perform effectively over time. Testing and certification standards may be applied to demonstrate its quality and durability, providing confidence in its performance.

Environmental Impact and Efficiency

The efficient operation of the 3400718 Compressor Water Outlet Tube contributes to reducing emissions and improving fuel efficiency in heavy-duty truck operations. By ensuring that the engine operates within its optimal temperature range, the tube supports the engine’s efficiency, which can lead to lower fuel consumption and reduced emissions 3.

Cummins Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industries, known for its wide range of products and strong reputation for quality and innovation. The company’s history and product offerings reflect its commitment to providing reliable and efficient solutions for the transportation sector.

Role of Part 3400718 Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube (Part 3400718) is integral to the efficient operation of the compressor coolant arrangement and compressor coolant plumbing. This component facilitates the controlled exit of coolant from the compressor, ensuring that the coolant system maintains optimal pressure and temperature levels.

In the compressor coolant arrangement, the outlet tube works in conjunction with the inlet tube and the compressor housing to create a sealed environment. This arrangement allows for the precise circulation of coolant, which absorbs heat generated by the compressor during operation. The consistent flow of coolant helps in dissipating this heat, thereby protecting the compressor from overheating and potential damage.

Within the compressor coolant plumbing, the outlet tube is a key connector that links various segments of the coolant pathway. It ensures that coolant is efficiently routed from the compressor to the heat exchanger or radiator, where it can release absorbed heat and return to the system at a lower temperature. This continuous cycle is essential for maintaining the compressor’s performance and longevity.

The integration of Part 3400718 into these systems underscores its importance in the overall thermal management of engine components. Proper installation and maintenance of this tube are necessary to ensure the reliability and efficiency of the coolant system.

Conclusion

The 3400718 Compressor Water Outlet Tube plays a vital role in the cooling systems of heavy-duty trucks, ensuring efficient coolant circulation and thermal management. Its robust design and precise construction contribute to the reliability and performance of the engine, supporting both efficiency and longevity. Proper maintenance and installation are essential to maximize the benefits of this Cummins part.

-

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Osgood, Libby, Cameron, Gayla, and Christensen, Emma. Engineering Mechanics: Statics. Creative Commons, 2024.

↩ -

Hiereth, Hermann, Prenninger, Peter, and Drexl, Klaus W. Charging the Internal Combustion Engine. Springer, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.