3400884

Idler Pulley

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

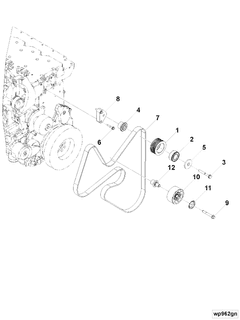

The Cummins 3400884 Idler Pulley is a component designed for use in commercial trucks. It serves a specific function within the engine’s accessory drive system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance can help in maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley used in belt drive systems to guide and maintain tension in the belt. It does not directly drive any component but ensures that the belt remains properly aligned and under the correct tension. This helps in the efficient transfer of power and reduces wear on both the belt and the driven components. In mechanical systems, idler pulleys play a role in ensuring smooth operation and longevity of the belt drive system 1.

Purpose of the 3400884 Idler Pulley

The Cummins 3400884 Idler Pulley is specifically designed to function within the engine’s accessory drive system of a truck. Its role is to maintain the proper tension of the belt that drives various engine accessories, such as the alternator, water pump, and air conditioning compressor. By keeping the belt tension consistent, the idler pulley helps ensure that these accessories operate efficiently and reliably.

Key Features

The Cummins 3400884 Idler Pulley is constructed with high-quality materials to ensure durability and performance. It typically features a robust housing, often made from cast iron or high-grade steel, which provides strength and resistance to wear. The pulley itself is usually made from a durable polymer or metal, designed to withstand the rigors of continuous operation. Additionally, the pulley may include features such as a built-in bearing to reduce friction and enhance smooth operation 2.

Benefits of Using the 3400884 Idler Pulley

Using the Cummins 3400884 Idler Pulley offers several advantages. It helps in maintaining optimal belt tension, which reduces the risk of belt slippage and associated wear on other components. This contributes to the overall efficiency of the engine’s accessory drive system. Additionally, by ensuring proper belt alignment and tension, the idler pulley can help extend the lifespan of the belt and the driven accessories, leading to reduced maintenance costs and improved reliability 3.

Installation Considerations

When installing the Cummins 3400884 Idler Pulley, it is important to follow best practices to ensure proper function and longevity. This includes ensuring that the engine is cool before beginning the installation process. The necessary tools, such as wrenches and alignment tools, should be prepared beforehand. Careful alignment of the pulley is crucial to maintain the correct belt tension and path. Following the manufacturer’s guidelines for torque specifications and alignment will help ensure a successful installation 4.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3400884 Idler Pulley is important to ensure its continued reliable operation. This includes periodic inspection for signs of wear or damage, such as cracks in the housing or excessive wear on the pulley surface. Lubricating the bearing, if applicable, can help reduce friction and wear. Common issues that may arise include belt slippage or noise, which can often be addressed by adjusting the tension or replacing worn components.

Compatibility and Application

The Cummins 3400884 Idler Pulley is designed for use in specific types of trucks and engine models. It is important to verify compatibility with the specific make and model of the truck to ensure proper fit and function. Application notes provided by Cummins can offer additional guidance on installation and usage.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Idler Pulley 3400884 Compatibility with Cummins Engines

The Idler Pulley 3400884, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part plays a role in the engine’s belt-driven systems, ensuring the smooth operation of ancillary components such as the alternator, water pump, and air conditioning compressor.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

The ISM series engines, including the ISM CM570, ISM CM570/870, ISM CM876, and ISM11 CM876 SN, are medium-duty diesel engines that are widely used in various applications such as trucks, buses, and construction equipment. The Idler Pulley 3400884 is compatible with these engines, ensuring that the belt-driven systems operate efficiently and reliably.

QSB Series Engines

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The QSB series engines, including the QSB6.7 CM850 (CM2850) and QSB7 CM2880 B117, are high-performance diesel engines designed for demanding applications such as agricultural machinery, marine vessels, and generators. The Idler Pulley 3400884 is engineered to fit these engines, providing the necessary support and alignment for the belt-driven systems.

QSM Series Engines

- QSM11 CM570

- QSM11 CM876

The QSM series engines, including the QSM11 CM570 and QSM11 CM876, are medium-duty diesel engines used in a variety of applications such as trucks, buses, and industrial equipment. The Idler Pulley 3400884 is compatible with these engines, ensuring that the belt-driven systems function optimally.

By ensuring compatibility with these engines, the Idler Pulley 3400884 helps maintain the performance and longevity of the belt-driven systems, contributing to the overall reliability and efficiency of the engine.

Role of Part 3400884 Idler Pulley in Engine Systems

The 3400884 Idler Pulley is an integral component within various engine systems, facilitating the smooth operation of several key elements.

In the drive system, the idler pulley works in conjunction with the drive belt to maintain proper tension. This ensures efficient power transmission from the engine to auxiliary components, enhancing overall engine performance.

When integrated with the fan system, the idler pulley helps in regulating the belt tension for the fan. This regulation is essential for optimal cooling of the engine, preventing overheating during operation.

Within the water pump system, the idler pulley plays a role in maintaining consistent belt tension. This consistency is vital for the water pump’s efficient operation, ensuring proper circulation of coolant throughout the engine.

In the mounting system, the idler pulley provides stability and support to the belt, reducing wear and tear on both the belt and the pulley itself. This contributes to the longevity of the engine components.

Lastly, in the alternator system, the idler pulley assists in keeping the belt taut, which is necessary for the alternator to generate electricity efficiently. This electricity is used to power the vehicle’s electrical systems and recharge the battery.

Overall, the 3400884 Idler Pulley is a fundamental component that supports the reliable and efficient operation of these engine systems.

Conclusion

The Cummins 3400884 Idler Pulley is a critical component in the accessory drive system of commercial trucks. Its role in maintaining proper belt tension ensures the efficient and reliable operation of engine accessories. Constructed with durable materials and designed for specific engine models, this part contributes to the overall performance and longevity of the vehicle. Regular maintenance and proper installation are essential to maximize its benefits and ensure the continued reliability of the truck’s engine system.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.