3413129

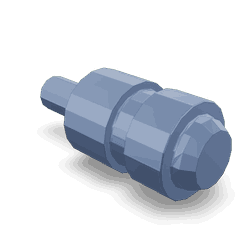

Check Valve

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3413129 Check Valve is a component designed for use in commercial truck systems. Its purpose is to regulate the flow of fluids within the system, ensuring that fluid moves in the intended direction and preventing backflow. This valve is integral to maintaining the efficiency and reliability of the truck’s systems, contributing to overall performance and longevity.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates by using a mechanism that opens when fluid flows in the correct direction and closes when the flow attempts to reverse. This functionality is vital in various fluid systems to prevent contamination, maintain pressure, and ensure the proper operation of equipment. Check valves are commonly used in water, gas, and hydraulic systems, among others 1.

Purpose of the Cummins 3413129 Check Valve

The Cummins 3413129 Check Valve plays a specific role in the operation of a truck, particularly within the fuel, lubrication, or hydraulic systems. It ensures that fluid flows in the correct direction, preventing backflow that could lead to system inefficiencies or damage. By maintaining the integrity of the fluid flow, this valve contributes to the stable operation of the truck’s systems, enhancing performance and reliability.

Key Features

The Cummins 3413129 Check Valve is constructed from durable materials, ensuring it can withstand the pressures and conditions of commercial truck systems. Its design includes elements that enhance its performance, such as a precise sealing mechanism to prevent leaks and a robust body to endure the operational stresses. Unique attributes of this valve may include its compact size for easy installation in tight spaces and its compatibility with a wide range of system configurations.

Benefits

The advantages provided by the Cummins 3413129 Check Valve include improved system efficiency through reliable fluid flow management, enhanced reliability by preventing backflow and system damage, and potential cost savings due to its durability and long service life. These benefits contribute to the overall performance and maintenance costs of commercial trucks 2.

Installation Considerations

When installing the Cummins 3413129 Check Valve, it is important to follow guidelines and best practices to ensure proper function. This includes orienting the valve correctly to allow fluid flow in the intended direction, using the required tools for installation, and ensuring compatibility with other system components. Proper installation is key to maximizing the valve’s performance and longevity.

Troubleshooting Common Issues

Common problems associated with check valves can include leaks, blockages, or failure to open or close properly. Potential causes may range from debris in the fluid to mechanical wear. Recommended troubleshooting steps include inspecting the valve for signs of damage or wear, cleaning or replacing components as necessary, and ensuring the valve is correctly installed and oriented.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3413129 Check Valve, regular maintenance is advised. This includes inspection intervals to check for wear or damage, cleaning procedures to remove any debris that may affect operation, and considering replacement when signs of significant wear or failure are observed. Proper maintenance helps maintain system efficiency and reliability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry for producing reliable and efficient components that contribute to the performance and longevity of commercial vehicles 3.

Compatibility with Cummins Engines

The Cummins Check Valve, identified by part number 3413129, is designed to prevent backflow, thereby maintaining the efficiency and longevity of the engine. Below is a detailed overview of its compatibility with various Cummins engines:

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

The Check Valve is compatible with the ISX series engines, which are known for their robust performance and reliability. These engines are often used in heavy-duty applications, and the Check Valve ensures that the fluid flow remains unidirectional, preventing any potential damage from backflow.

ISX15 Series Engines

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX15 series engines benefit from the Check Valve’s ability to maintain fluid integrity. These engines are designed for high-performance applications, and the Check Valve plays a crucial role in ensuring that the fluid flow is consistent and reliable.

QSX15 Series Engines

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX15 series engines, which are equipped with the Check Valve, are designed for applications that require high power and efficiency. The Check Valve ensures that the fluid flow is optimized, contributing to the overall performance and durability of these engines.

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X15 series engines also rely on the Check Valve to maintain fluid flow integrity. These engines are engineered for demanding applications, and the Check Valve ensures that the fluid flow remains unidirectional, preventing any potential issues that could arise from backflow.

Role of 3413129 Check Valve in Engine Systems

The 3413129 Check Valve is an integral component in the operation of various engine systems, ensuring efficient and reliable performance. In the context of a Brake Campaign Kit, the Check Valve helps maintain consistent pressure within the braking system, preventing any unwanted backflow that could compromise braking efficiency.

When integrated into a Brake Overhaul Kit, the Check Valve assists in the restoration and optimization of the braking system’s performance by ensuring that fluid flows in the correct direction, thereby enhancing the overall safety and reliability of the vehicle’s braking mechanism.

In conjunction with the Engine Brake Lever, the Check Valve plays a supportive role by regulating the pressure applied to the engine braking system. This ensures that the lever operates smoothly and effectively, contributing to the engine’s ability to decelerate the vehicle without unnecessary strain on the braking components.

Within the ISX Brake Tune-Up kit, the Check Valve is essential for fine-tuning the brake system. It helps in maintaining the precise pressure levels required for optimal brake performance, which is vital for the longevity and efficiency of the brake system.

The Rocker Lever and Rocker Lever Assembly also benefit from the inclusion of the Check Valve. By preventing reverse flow, the Check Valve ensures that the pressure applied to these components is consistent, which is important for their smooth operation and durability.

Finally, in the Rocker Lever Top Level Assembly, the Check Valve ensures that the pressure distribution is even and reliable. This is particularly important for the top-level assembly, where precise pressure control can significantly impact the performance and lifespan of the entire rocker lever system.

Conclusion

The Cummins 3413129 Check Valve is a critical component in ensuring the proper flow of fluids within commercial truck systems. Its role in preventing backflow contributes to the efficiency, reliability, and longevity of the truck’s systems. Proper installation, maintenance, and understanding of its compatibility with various Cummins engines are essential for maximizing its performance and benefits.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.