This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

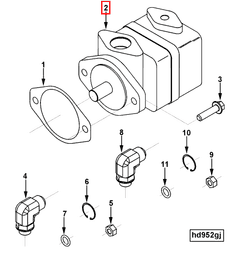

The Cummins 3415378 Hydraulic Pump is a component designed for use in commercial trucks. It serves a significant role in the hydraulic systems of these vehicles, contributing to various operational functions that enhance performance and efficiency.

Basic Concepts of Hydraulic Pumps

Hydraulic systems utilize pressurized fluid to transfer power. At the heart of these systems are hydraulic pumps, which convert mechanical energy into hydraulic energy. This process involves drawing in fluid at low pressure and expelling it at a higher pressure, thereby enabling the operation of hydraulic actuators and other components. The efficiency and reliability of these pumps are vital for the smooth functioning of hydraulic systems 1.

Purpose of the Cummins 3415378 Hydraulic Pump

This Cummins part is specifically designed to meet the demanding requirements of commercial truck operations. It plays a role in powering various hydraulic functions within the truck, such as braking systems, steering mechanisms, and other auxiliary systems that rely on hydraulic pressure. Its design ensures consistent performance under varying load conditions, contributing to the overall efficiency and safety of the vehicle.

Key Features

This part boasts several key features that enhance its performance and durability. Its design incorporates high-quality materials that resist wear and corrosion, ensuring longevity. Technological advancements within the pump improve its efficiency and reliability, making it a robust choice for commercial applications.

Benefits

The advantages of this part include enhanced efficiency, which leads to better fuel economy and reduced operational costs. Its reliable performance ensures minimal downtime, contributing to increased productivity. Additionally, the pump’s design allows for improved performance under a wide range of operating conditions, making it a versatile component for commercial trucks.

Installation and Integration

When installing this part, it is important to consider compatibility with the truck’s existing systems. Proper installation involves following manufacturer guidelines to ensure the pump integrates seamlessly with the vehicle’s hydraulic system. This process includes verifying connections, ensuring proper alignment, and conducting initial tests to confirm functionality.

Troubleshooting Common Issues

Common issues with hydraulic pumps can include leaks, unusual noises, or a decrease in performance. Diagnosing these problems involves a systematic approach, starting with a visual inspection for leaks or damage. Further diagnostic steps may include pressure testing and analyzing the pump’s operation under load. Addressing these issues promptly can prevent more significant problems and ensure the pump’s optimal performance.

Maintenance Practices

Regular maintenance of this part is crucial for its longevity and efficiency. This includes routine inspections for wear and damage, changing the hydraulic fluid at recommended intervals, and checking for proper operation of all components. Adhering to a maintenance schedule helps prevent unexpected failures and extends the lifespan of the pump.

Safety Considerations

Working with hydraulic systems requires adherence to safety practices to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the system is depressurized before performing maintenance, and following all manufacturer guidelines for safe operation and handling of hydraulic fluids.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and automotive markets. The company’s reputation for reliability and performance is reflected in its wide range of products, including the Cummins 3415378 Hydraulic Pump.

Cummins Hydraulic Pump 3415378 Compatibility

This part is designed to be compatible with a range of Cummins engines, ensuring reliable hydraulic performance across various applications. This hydraulic pump is engineered to fit seamlessly with the following engines:

Cummins 6C8.3

The 6C8.3 engine is a robust and efficient power unit, often utilized in heavy-duty applications. The hydraulic pump 3415378 is engineered to integrate smoothly with this engine, providing the necessary hydraulic support for various functions.

Cummins B5.9 GAS PLUS CM556 and C GAS PLUS CM556

Both the B5.9 GAS PLUS CM556 and C GAS PLUS CM556 engines benefit from the hydraulic pump 3415378. These engines are known for their reliability and performance in demanding environments. The hydraulic pump ensures that these engines maintain optimal hydraulic pressure, enhancing overall efficiency and functionality.

Cummins ISL9 CM2150 SN and ISL9.5 CM2880 L138

The ISL9 CM2150 SN and ISL9.5 CM2880 L138 engines are part of Cummins’ high-performance lineup, often used in applications requiring significant power and durability. The hydraulic pump 3415378 is designed to work with these engines, ensuring that they deliver consistent hydraulic performance, which is crucial for the smooth operation of various systems.

Cummins L8.9

The L8.9 engine is another high-performance unit from Cummins, known for its strength and reliability. The hydraulic pump 3415378 is compatible with this engine, providing the necessary hydraulic support to maintain the engine’s operational efficiency and performance.

Role of Part 3415378 Hydraulic Pump in Engine Systems

The hydraulic pump, specifically part 3415378, is an integral component within various engine systems, facilitating the movement of hydraulic fluid to generate power and control mechanisms. Its role can be understood through its interaction with several key components:

Interaction with the Pump System

The hydraulic pump, part 3415378, works in conjunction with the primary pump system to ensure consistent fluid circulation. This interaction is essential for maintaining pressure levels within the hydraulic lines, which in turn drives the actuators and other hydraulic components. The pump’s efficiency directly influences the performance and reliability of the entire hydraulic system.

Contribution to Auxiliary Systems

In auxiliary systems, the hydraulic pump plays a significant role in powering secondary functions such as steering, braking, and suspension adjustments. By providing the necessary hydraulic pressure, it enables these systems to operate smoothly and responsively. The pump’s ability to deliver precise fluid volumes ensures that auxiliary components function within their optimal parameters, enhancing overall vehicle performance and safety.

Enhancing System Integration

The integration of part 3415378 within the engine systems allows for seamless operation between mechanical and hydraulic components. This pump ensures that hydraulic functions are synchronized with engine operations, contributing to efficient power transmission and control. Its reliable performance is key to maintaining the balance and effectiveness of the interconnected systems.

Supporting Complex Operations

In more complex engine setups, the hydraulic pump assists in managing multiple functions simultaneously. Whether it’s controlling variable valve timing or powering advanced fuel injection systems, the pump’s role is vital. Its consistent performance under varying conditions ensures that these sophisticated operations are executed with precision and reliability.

Through its interactions with the pump and auxiliary systems, part 3415378 hydraulic pump significantly enhances the functionality and efficiency of engine systems. Its reliable operation is fundamental to the smooth and effective performance of both primary and secondary hydraulic functions.

Conclusion

The Cummins 3415378 Hydraulic Pump is a critical component in the hydraulic systems of commercial trucks, designed to enhance performance and efficiency. Its key features, benefits, and compatibility with various Cummins engines make it a reliable choice for demanding applications. Proper installation, maintenance, and adherence to safety practices are essential for maximizing the pump’s performance and longevity.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.