This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

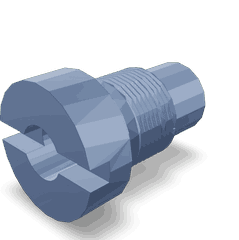

The Cummins 3417166 Check Valve is a specialized component designed for use in commercial truck systems. Its primary role is to ensure the unidirectional flow of fluids within the system, preventing backflow which could lead to inefficiencies or damage. This valve is integral to maintaining the optimal performance and reliability of commercial trucks, particularly in their fuel, lubrication, or hydraulic systems.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a passive device that allows fluid to flow through it in only one direction. It operates using a mechanism that opens when the fluid flows in the correct direction and closes when the flow attempts to reverse. This mechanism can be a spring-loaded plunger, a swing gate, or a ball. Check valves are commonly used in various fluid systems to prevent backflow, protect equipment, and maintain system integrity 1.

Purpose of the Cummins 3417166 Check Valve

The Cummins 3417166 Check Valve plays a specific role in the operation of commercial trucks by ensuring the proper flow of fluids within the system. In the fuel system, it prevents fuel from flowing back into the supply line, which could cause contamination or pressure issues. In lubrication systems, it maintains consistent oil flow to critical components, ensuring they remain properly lubricated. For hydraulic systems, the valve helps maintain pressure and prevents hydraulic fluid from returning to the reservoir, which could lead to system malfunctions 2.

Key Features

The Cummins 3417166 Check Valve is constructed from durable materials, typically including high-grade metals and synthetic rubber seals, to withstand the harsh conditions of commercial truck operations. Its design incorporates a spring-loaded mechanism that ensures reliable operation under varying pressure conditions. Unique attributes such as corrosion resistance and high-temperature tolerance enhance its performance and longevity in demanding environments 3.

Benefits

The Cummins 3417166 Check Valve offers several advantages. It improves system efficiency by ensuring unidirectional fluid flow, which reduces the risk of contamination and system wear. By preventing backflow, it protects sensitive components from damage. Additionally, the valve contributes to overall system reliability, minimizing the likelihood of unexpected failures and reducing maintenance requirements 4.

Installation Considerations

When installing the Cummins 3417166 Check Valve, it is important to follow guidelines to ensure proper function. The valve should be oriented correctly, with the flow arrow indicating the direction of fluid movement. Required tools include wrenches for securing connections and a torque wrench for tightening fittings to the manufacturer’s specifications. Preparatory steps may involve cleaning the installation site and inspecting the valve for any damage prior to installation 5.

Troubleshooting Common Issues

Frequent problems associated with check valves include leaks and malfunctions. Leaks may occur due to worn seals or improper installation, while malfunctions can result from debris blocking the valve or a failed spring mechanism. Diagnostic steps include inspecting the valve for physical damage, checking for proper orientation, and ensuring there is no obstruction in the flow path. Solutions may involve cleaning the valve, replacing worn components, or reinstalling the valve correctly 6.

Maintenance Tips

Routine maintenance of the Cummins 3417166 Check Valve is crucial for prolonged performance. Inspection intervals should be aligned with the truck’s maintenance schedule, typically every six months or as recommended by the manufacturer. Cleaning procedures involve removing the valve and flushing it with a compatible solvent to remove any contaminants. Replacement should be considered if there are signs of wear, corrosion, or if the valve fails to operate correctly during routine checks 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for innovation and quality in the commercial truck industry. The company offers a wide range of products, including engines, powertrains, and aftermarket parts, designed to meet the demanding requirements of commercial transportation. Cummins is recognized for its commitment to customer satisfaction and technological advancement 8.

Compatibility of Cummins Check Valve 3417166

The Cummins Check Valve part number 3417166 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This check valve is engineered to prevent backflow, which is crucial in maintaining the integrity of the engine’s hydraulic and fuel systems.

ISX Series Engines

The ISX CM570 and ISX CM870 engines are part of Cummins’ high-performance lineup, known for their robust design and efficiency. The check valve 3417166 is specifically tailored to fit these engines, providing a reliable barrier against reverse flow in the fuel and hydraulic systems. This ensures that the engine operates smoothly, maintaining consistent pressure and flow rates.

QSK Series Engines

The QSK19 CM500 engine is another high-output engine from Cummins, designed for demanding applications. The check valve 3417166 is compatible with this engine, ensuring that the hydraulic and fuel systems function without the risk of backflow. This compatibility is crucial for maintaining the engine’s performance and longevity.

VTA Series Engines

The VTA903 CM2250 V105 engine is a powerful and versatile engine, often used in heavy-duty applications. The check valve 3417166 is engineered to fit this engine, providing essential protection against backflow. This ensures that the engine’s hydraulic and fuel systems operate efficiently, contributing to the overall reliability and performance of the engine.

By integrating the check valve 3417166 into these engines, Cummins ensures that the hydraulic and fuel systems are protected, leading to improved engine performance and longevity. This compatibility highlights Cummins’ commitment to providing high-quality components that enhance the functionality of their engines 9.

Role of Part 3417166 Check Valve in Engine Systems

The 3417166 Check Valve is an essential component in maintaining the integrity and efficiency of various engine systems. Its primary function is to allow fluid flow in one direction while preventing backflow, which is vital for the consistent operation of fuel systems.

Integration with Fuel Control Housing

When integrated into the fuel control housing, the 3417166 Check Valve ensures that fuel flows smoothly into the housing without any reverse flow. This unidirectional flow is important for maintaining the precise fuel-air mixture required for optimal engine performance. The check valve helps in stabilizing the fuel pressure within the housing, which is essential for the accurate functioning of the fuel control module.

Functionality in Fuel Control Module

In the fuel control module, the 3417166 Check Valve plays a significant role in regulating fuel delivery. By preventing backflow, it ensures that the fuel control module receives a consistent supply of fuel, allowing it to modulate the fuel injection process effectively. This results in improved fuel efficiency and reduced emissions.

Role in Fuel Pump Systems

When used in conjunction with a fuel pump, particularly a gear fuel pump, the 3417166 Check Valve helps maintain a steady fuel flow. The gear fuel pump generates high-pressure fuel, and the check valve ensures that this pressure is not lost due to backflow. This consistent pressure is necessary for the fuel pump to deliver fuel efficiently to the engine’s combustion chambers.

Ensuring Efficient Gear Fuel Pump Operation

In gear fuel pump systems, the 3417166 Check Valve is positioned to prevent fuel from flowing back into the pump once it has been pressurized. This ensures that the gear fuel pump operates under optimal conditions, reducing the risk of cavitation and improving the overall reliability of the fuel system. The check valve also contributes to the longevity of the gear fuel pump by maintaining stable pressure levels 10.

Conclusion

The Cummins 3417166 Check Valve is a critical component in the maintenance and operation of commercial truck systems. By ensuring unidirectional fluid flow, it enhances system efficiency, protects sensitive components, and contributes to overall system reliability. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the performance and longevity of this Cummins part.

-

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659765.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659765.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5659765.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Engine Compatibility Guide. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Engine System Integration Guide. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.