3417970

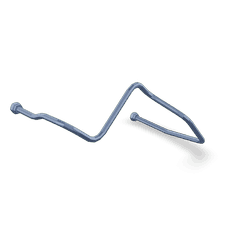

Compressor Water Outlet Tube

Cummins®

IN STOCK

10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Compressor Water Outlet Tube, identified by part number 3417970, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This tube is integral to the cooling system of heavy-duty trucks, ensuring the compressor operates within optimal temperature ranges. Cummins is renowned for its commitment to quality and innovation in manufacturing components that enhance the performance and reliability of vehicle systems 1.

Function and Operation

The Compressor Water Outlet Tube facilitates the flow of coolant from the compressor to other parts of the truck’s cooling system. It plays a role in managing coolant distribution, which is vital for maintaining the compressor’s temperature. By ensuring a consistent flow of coolant, the tube helps prevent overheating, which can lead to compressor failure or reduced efficiency 2.

Purpose of the Compressor Water Outlet Tube

In the operation of a truck, the Compressor Water Outlet Tube contributes to the efficiency and reliability of the compressor system. It ensures that the compressor remains at an optimal operating temperature, which is crucial for its performance and longevity. By managing coolant flow effectively, the tube supports the overall efficiency of the truck’s cooling system 3.

Key Features

The Compressor Water Outlet Tube is designed with several features that enhance its performance and durability. It is typically made from high-quality materials resistant to corrosion and high temperatures. The design may include specific fittings or connections that ensure a secure and leak-free attachment to the compressor and other components of the cooling system. These features contribute to the tube’s ability to withstand the demanding conditions of heavy-duty truck operations.

Benefits

The use of the Compressor Water Outlet Tube offers several advantages. It contributes to improved compressor longevity by ensuring optimal temperature management. Enhanced system efficiency is another benefit, as effective coolant flow supports the overall performance of the truck’s cooling system. Additionally, by reducing the risk of compressor failure, the tube can lead to potential cost savings for fleet operators through reduced maintenance and repair needs.

Installation and Compatibility

Proper installation of the Compressor Water Outlet Tube is crucial for its effective operation. It is important to follow manufacturer guidelines to ensure compatibility with various truck models and compressor systems. Specific requirements may include the use of compatible fittings or adapters, and careful attention to the tube’s orientation and connection points to prevent leaks and ensure efficient coolant flow.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the longevity and optimal performance of the Compressor Water Outlet Tube. This may include regular inspections for signs of wear, corrosion, or leaks, and cleaning or replacing the tube as necessary. Troubleshooting common issues, such as leaks or reduced coolant flow, may involve checking connections, inspecting for damage, and ensuring the tube is properly installed and compatible with the system.

Safety Considerations

When working with the Compressor Water Outlet Tube, it is important to observe safety protocols and precautions. This includes proper handling during installation and maintenance to prevent injury or damage to the component. Following manufacturer guidelines for installation and maintenance procedures can help minimize risks associated with working on the truck’s cooling system.

Environmental Impact

The production, use, and disposal of the Compressor Water Outlet Tube have environmental implications. Cummins is committed to mitigating its ecological footprint through various efforts, including the use of sustainable materials and manufacturing processes, and programs for the recycling and responsible disposal of components. Understanding these impacts and the manufacturer’s efforts can inform more environmentally conscious decisions in the selection and maintenance of truck components.

Cummins Overview

Cummins has a long-standing reputation in the industry for its innovation and quality in manufacturing automotive components. With a history of developing reliable and efficient solutions for the transportation sector, Cummins continues to lead in the design and production of parts that enhance vehicle performance and durability. Its commitment to excellence is evident in the design and functionality of components like the Compressor Water Outlet Tube.

Compatibility of Compressor Water Outlet Tube (Part 3417970) with Cummins Engines

The Compressor Water Outlet Tube (Part 3417970) manufactured by Cummins is designed to fit a range of Cummins engines, ensuring efficient water flow management within the engine’s cooling system. Here is a detailed overview of its compatibility with various Cummins engine models:

ISM Series Engines

- ISM CM570: This engine model is compatible with the Compressor Water Outlet Tube, ensuring proper water flow from the compressor to the cooling system.

- ISM CM570/870: This dual-model engine benefits from the precise fit of the part, maintaining optimal cooling efficiency.

- ISM CM876: The ISM CM876 engine also integrates seamlessly with the Compressor Water Outlet Tube, enhancing the cooling process.

ISM11 Series Engines

- ISM11 CM876 SN: This variant of the ISM11 series is engineered to work with the Compressor Water Outlet Tube, ensuring that the cooling system operates at peak performance.

M11 Series Engines

- M11 CELECT PLUS: The M11 CELECT PLUS engine is designed to utilize the Compressor Water Outlet Tube, providing reliable water flow management.

- M11 MECHANICAL: This mechanical version of the M11 engine also fits the part, ensuring that the cooling system functions effectively.

QSM11 Series Engines

- QSM11 CM570: The QSM11 CM570 engine is compatible with the Compressor Water Outlet Tube, ensuring that the cooling system maintains its efficiency.

Each of these engine models relies on the Compressor Water Outlet Tube to manage water flow effectively, ensuring that the engine operates within optimal temperature ranges. This compatibility highlights the versatility and reliability of the part across different engine configurations.

Role of Part 3417970 Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube, identified by part number 3417970, is an essential component in the thermal management system of engine setups. Its primary function is to facilitate the efficient flow of coolant from the compressor to other parts of the engine system.

In the context of the compressor coolant arrangement, the Compressor Water Outlet Tube acts as a conduit. It ensures that the coolant, after absorbing heat from the compressor, is effectively directed towards the radiator or other cooling components. This process is vital for maintaining optimal operating temperatures, thereby enhancing the overall performance and longevity of the compressor.

Moreover, the tube’s design and placement within the engine system allow for minimal resistance to coolant flow. This characteristic is important for preventing hotspots and ensuring uniform cooling across the compressor and adjacent components. The consistent flow of coolant helps in stabilizing the temperature, which is particularly beneficial during high-stress operations or in environments where the engine is subjected to extreme conditions.

Additionally, the integration of the Compressor Water Outlet Tube within the coolant arrangement supports the engine’s thermal efficiency. By efficiently managing the heat dissipation process, the tube contributes to the stability of the compressor’s performance, reducing the risk of thermal-related failures.

Conclusion

In summary, the Compressor Water Outlet Tube (part 3417970) plays a significant role in the thermal management of engine systems by ensuring effective coolant flow from the compressor to other cooling components, thereby supporting the engine’s performance and reliability. Proper installation, maintenance, and understanding of its compatibility with various Cummins engines are crucial for maximizing its benefits and ensuring the longevity of the compressor system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.