FINAL SALE. No returns or exchanges.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

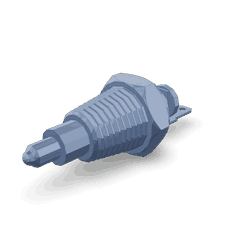

The Switch, Temperature (Part #3419045), manufactured by Cummins, is a critical component designed to monitor and regulate engine temperature in heavy-duty truck systems. This part ensures that the engine operates within safe temperature ranges, contributing to optimal performance and longevity 4.

Basic Concepts of Temperature Switches

Temperature switches are devices that monitor temperature changes and trigger electrical responses based on those changes. Within automotive systems, these switches function by detecting temperature variations and activating or deactivating circuits to maintain optimal operating conditions. The principle of operation involves thermal expansion and electrical conductivity, where a bimetallic strip within the switch bends in response to temperature changes, making or breaking an electrical contact 1.

Purpose and Role in Truck Operation

The Switch, Temperature in heavy-duty trucks is designed to monitor and regulate engine temperature. It ensures that the engine does not overheat by activating cooling systems when necessary. This contributes to the overall efficiency and safety of truck operations by preventing engine damage and ensuring consistent performance under varying conditions 2.

Key Features

The Cummins Switch, Temperature (Part #3419045) features a robust design that includes high-quality materials to withstand the harsh conditions of heavy-duty truck environments. The switch is constructed with durable metals and precision-engineered components to ensure reliable performance. Additionally, it may incorporate unique technological integrations such as corrosion-resistant coatings and advanced thermal sensors to enhance accuracy and longevity 3.

Benefits

The Switch, Temperature offers several benefits, including improved engine performance through precise temperature regulation. It enhances safety features by preventing engine overheating, which can lead to severe damage. Fleet operators may also experience potential cost savings due to reduced maintenance needs and extended engine life resulting from consistent temperature management 4.

Installation and Integration

Proper installation of the Switch, Temperature within a truck’s engine system involves connecting it to the appropriate sensors and control units. It should be integrated with other components such as the engine control module (ECM) and cooling system to ensure optimal functionality. Following manufacturer guidelines during installation is important to maintain the switch’s performance and reliability 1.

Troubleshooting and Maintenance

Common issues associated with temperature switches include inaccurate readings and failure to activate cooling systems. Solutions may involve recalibrating the switch or replacing faulty components. Maintenance tips to ensure the longevity and reliability of the Switch, Temperature include regular inspection for signs of wear or corrosion, and ensuring that all connections are secure and free from debris. Diagnostic procedures for identifying faults may involve testing the electrical continuity and verifying the accuracy of temperature readings 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company is committed to delivering reliable and efficient components that meet the demanding requirements of heavy-duty applications 3.

Role of Part 3419045 Switch, Temperature in Engine Systems

The part 3419045 Switch, Temperature is an integral component in the thermal management of engine systems. It operates in conjunction with the coolant temperature sensor to monitor the temperature of the engine coolant. When the coolant reaches a specific threshold, the switch activates, signaling the engine control unit (ECU) to adjust various parameters to maintain optimal engine performance.

In the context of the engine’s cooling system, the switch works alongside the thermostat, radiator, and water pump. The thermostat regulates the flow of coolant based on temperature readings from the switch. If the coolant is too hot, the thermostat opens to allow more coolant to flow through the radiator, where it is cooled before returning to the engine. Conversely, if the coolant is too cold, the thermostat restricts flow to warm the engine more quickly.

The water pump plays a role in circulating the coolant throughout the engine and radiator. The switch ensures that the water pump operates efficiently by providing accurate temperature data to the ECU. This helps prevent overheating and ensures the engine operates within its designed temperature range.

Additionally, the switch interacts with the ECU to control the operation of the engine’s cooling fan. When the coolant temperature exceeds a certain point, the switch signals the ECU to turn on the fan, which draws air through the radiator to cool the coolant more rapidly. This interaction is vital for preventing overheating during periods of high engine load or in hot ambient conditions.

Overall, the part 3419045 Switch, Temperature is a key component in the engine’s thermal management system, ensuring that the engine maintains optimal operating temperatures under varying conditions 4.

Conclusion

The Switch, Temperature (Part #3419045) by Cummins is a vital component in the thermal management of heavy-duty truck engines. Its role in monitoring and regulating engine temperature ensures optimal performance, safety, and longevity of the engine. Proper installation, regular maintenance, and understanding its integration within the engine’s cooling system are essential for maximizing the benefits of this part.

-

Rob Thompson, Automotive Maintenance: Light Repair, Cengage Learning, 2019.

↩ ↩ -

P. A. Lakshminarayanan, Avinash Kumar Agarwal, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer, 2019.

↩ ↩ -

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ ↩ -

Thorsten Boger, Willard Cutler, Reducing Particulate Emissions in Gasoline Engines, SAE International, 2018.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.