This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

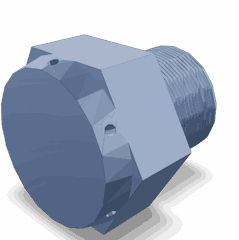

The Damper Cooling Nozzle (Part #3421180), manufactured by Cummins, is a component designed to enhance the cooling efficiency of heavy-duty truck engines. Its purpose is to facilitate the cooling process by directing coolant flow to critical areas within the engine, thereby maintaining optimal operating temperatures and ensuring reliable performance 1.

Basic Concepts of Damper Cooling Nozzles

A damper cooling nozzle is a specialized component within an engine’s cooling system. It functions by regulating the flow of coolant to specific engine components, such as the piston crown or cylinder head, where cooling is most needed. The principles behind its operation involve the strategic placement and design of the nozzle to maximize cooling efficiency while minimizing the risk of coolant leakage or blockage 2.

Role of the Damper Cooling Nozzle in Truck Operation

This Cummins part plays a significant role in the operation of a truck by contributing to the engine’s cooling system. It helps maintain the engine’s temperature within a safe range, which is vital for preventing overheating and ensuring consistent performance. By directing coolant to areas prone to high temperatures, the nozzle aids in dissipating heat more effectively, which can lead to improved engine longevity and reliability 3.

Key Features of the Cummins Damper Cooling Nozzle

The Damper Cooling Nozzle (Part #3421180) is characterized by several key features that enhance its functionality. Its design is engineered to provide precise coolant distribution, ensuring that critical engine components receive adequate cooling. The materials used in its construction are selected for their durability and resistance to corrosion, which contributes to the nozzle’s longevity and reliability in demanding operating conditions.

Benefits of Using the Cummins Damper Cooling Nozzle

Utilizing the Damper Cooling Nozzle (Part #3421180) offers several benefits. It contributes to improved engine efficiency by maintaining optimal operating temperatures, which can lead to better fuel economy. Additionally, by reducing the thermal stress on engine components, it helps minimize wear and tear, potentially extending the engine’s lifespan. Enhanced overall performance is another advantage, as the efficient cooling provided by the nozzle allows the engine to operate more reliably under various conditions.

Troubleshooting and Maintenance Suggestions

To ensure the Damper Cooling Nozzle (Part #3421180) operates effectively, regular maintenance and troubleshooting are recommended. Inspecting the nozzle for signs of wear, corrosion, or blockage can help identify potential issues early. Ensuring that the coolant system is free of contaminants and that the coolant level is maintained at the appropriate level are also important maintenance practices. If issues arise, such as reduced cooling efficiency or coolant leaks, addressing them promptly can help maintain the nozzle’s performance and longevity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. Its product range includes engines and components designed to meet the demanding requirements of various applications, from on-highway to off-highway and industrial uses.

Integration with Cummins Engines

This part is designed to fit seamlessly with a range of Cummins engines. For the QSV81G and QSV91G engines, the Damper Cooling Nozzle is engineered to integrate smoothly, providing efficient cooling and maintaining the engine’s operational temperature. In the case of the QSW/QSV82 engines, the nozzle is specifically tailored to fit the unique design of these models, ensuring that the cooling system operates at peak efficiency. The QSW27 and QSW36 engines also benefit from this part, with the Damper Cooling Nozzle designed to fit perfectly within their cooling systems, contributing to the overall reliability and performance of the engine. Lastly, the QSW73 engine incorporates the Damper Cooling Nozzle as a critical component, ensuring that the engine’s cooling system functions optimally, thereby enhancing the engine’s durability and efficiency.

Role of Part 3421180 Damper Cooling Nozzle in Engine Systems

The Damper Cooling Nozzle, identified by part number 3421180, is an integral component in the thermal management of various engine systems. Its primary function is to direct cooling fluid to the damper assembly, ensuring optimal operating temperatures are maintained.

Integration with Engine Components

-

Assembly Housing Gear and Camshaft: The nozzle is strategically positioned to cool the assembly housing gear and the camshaft. This helps in reducing thermal expansion and maintaining precise clearances between the cam and the gear, which is essential for smooth engine operation.

-

L8+V16 Assy and CCW Drive: In engines with L8+V16 assemblies and counter-clockwise (CCW) drives, the damper cooling nozzle plays a significant role. It ensures that the drive components remain within their thermal limits, preventing overheating that could lead to mechanical failures.

-

Accessory Drive and Front Gear Train Accessory: The nozzle also aids in cooling the accessory drive and the front gear train accessory. This is particularly important in high-performance engines where these components are subjected to significant thermal loads.

-

Heat Exchanger: The damper cooling nozzle works in conjunction with the heat exchanger to manage the overall thermal environment of the engine. Efficient cooling of the damper assembly contributes to the effectiveness of the heat exchanger in dissipating heat away from critical engine components.

-

Free End Cover Assembly and Gear Assembly Housing: Cooling the free end cover assembly and the gear assembly housing is vital for the longevity and reliability of these components. The nozzle ensures that these parts do not exceed their maximum operating temperatures, thereby prolonging their service life.

-

Gear Equipped Housing and Gear Mounting Housing: These housings are often in close proximity to high-heat areas of the engine. The damper cooling nozzle helps in maintaining a stable temperature, which is essential for the structural integrity and functional reliability of these housings.

Conclusion

In summary, the Damper Cooling Nozzle (part 3421180) is a key component in the thermal management strategy of modern engine systems. Its effective placement and function ensure that various engine components operate within their designed thermal envelopes, contributing to overall engine performance and durability.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Watson, Ben. Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning, 2011.

↩ -

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.