This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3500334 Thrust Collar is a component designed for use in heavy-duty truck engines. Its purpose is to manage axial loads and maintain proper alignment within the engine, contributing to the overall efficiency and reliability of the engine system.

Basic Concepts of Thrust Collars

A thrust collar is a mechanical component that plays a role in controlling axial movement within an engine. It interacts with other engine components to ensure that parts remain properly aligned and that excessive movement is minimized. This helps in maintaining the integrity and performance of the engine over time 1.

Purpose of the 3500334 Thrust Collar

The 3500334 Thrust Collar is specifically designed to manage axial loads in truck engines. It helps in maintaining the proper alignment of engine components, which is vital for the smooth operation of the engine. By controlling axial movement, it contributes to the stability and durability of the engine system 2.

Key Features

The 3500334 Thrust Collar is characterized by its robust design and material composition. It is crafted from high-quality materials that offer durability and resistance to wear. These features enhance its performance and ensure it can withstand the demanding conditions within a heavy-duty truck engine.

Benefits

The use of the 3500334 Thrust Collar offers several advantages. It contributes to improved engine efficiency by ensuring components remain properly aligned. This reduces wear on connecting components and enhances the overall performance of the engine. Additionally, it helps in maintaining consistent engine operation, which is crucial for heavy-duty applications 3.

Installation and Compatibility

Proper installation of the 3500334 Thrust Collar is important for its effective function. It requires careful alignment and may necessitate specific preparatory steps to ensure it fits correctly within the engine system. Compatibility with various engine models should be verified to ensure optimal performance and integration.

Maintenance and Troubleshooting

Regular maintenance of the 3500334 Thrust Collar is recommended to ensure its longevity and optimal performance. This includes periodic inspections for wear and proper alignment. Common issues may include misalignment or wear, which can be addressed through proper troubleshooting and, if necessary, replacement of the component.

Performance Impact

The 3500334 Thrust Collar contributes to the overall performance and reliability of the engine. By managing axial loads and maintaining component alignment, it plays a role in enhancing fuel efficiency and power output. Its proper function is integral to the consistent and efficient operation of the engine.

Cummins Corporation

Cummins Inc. is a well-established manufacturer in the heavy-duty truck industry, known for its wide range of engine and component products. The company has a history of innovation and quality, providing solutions that meet the demanding requirements of heavy-duty applications.

Cummins Thrust Collar 3500334 in Engine Applications

The Cummins Thrust Collar, part number 3500334, is a critical component in various engine configurations. This part is integral to the operational integrity of engines, ensuring that the rotating components are properly aligned and supported.

L10 MECHANICAL Engines

In the L10 MECHANICAL engines, the thrust collar plays a pivotal role in maintaining the alignment of the crankshaft. It helps to counteract the axial thrust generated by the pistons, ensuring that the engine operates smoothly and efficiently. The L10 MECHANICAL engines, known for their robust design and reliability, benefit significantly from the precision engineering of the thrust collar.

Group Applications

The thrust collar is also used in various engine groups where it provides essential support and alignment. Its design ensures that the rotational forces are evenly distributed, reducing wear and tear on other engine components. This makes it a vital part in maintaining the longevity and performance of the engines.

The use of the thrust collar in these engines underscores Cummins’ commitment to quality and durability, ensuring that the engines perform optimally under various conditions.

Role of Part 3500334 Thrust Collar in Engine Systems

The 3500334 Thrust Collar is an integral component in the efficient operation of various engine systems, particularly those involving turbochargers. This component works in conjunction with several key elements to ensure optimal performance and longevity of the turbocharger and associated systems.

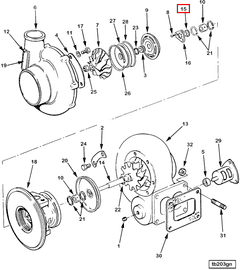

Integration with Turbocharger Components

In the context of an Aftermarket Turbocharger, the Thrust Collar plays a significant role in maintaining the axial position of the rotor assembly. It interfaces directly with the Turbocharger Core Assembly and the Turbocharger Rotor Assembly, providing necessary support and stability during high-speed operations.

Functionality in Core and Housing Systems

When considering the Core and Housing Kit or a Pre-set Turbine Housing Kit, the Thrust Collar ensures that the internal components, such as the Turbocharger Actuator Kit and the Turbocharger and Connection systems, operate within specified tolerances. This is essential for preventing undue wear and tear on the Turbocharger Core Assembly.

Performance and Repair Applications

For systems utilizing Performance Parts or Performance Parts AFC and Non AFC, the Thrust Collar is vital in enhancing the durability and efficiency of the turbocharger. In scenarios where a Turbocharger Repair Kit is employed, the correct installation and function of the Thrust Collar are paramount to restoring the turbocharger to its peak operational condition.

Specific Turbocharger Models

In the H2 Turbocharger and Turbocharger H2C models, the Thrust Collar is designed to handle the specific demands of these high-performance units. It ensures that the Rotor Assembly remains stable, even under extreme conditions, thereby contributing to the overall reliability of the turbocharger.

Application in Diverse Turbocharger Systems

Whether dealing with a standard Turbocharger or a more complex Dina Mexico Conv system, the Thrust Collar’s role remains consistent: to provide axial support and stability to the turbocharger’s moving parts. This is particularly important in maintaining the integrity of the Turbocharger Location within the engine system.

Conclusion

In summary, the 3500334 Thrust Collar is a key component in various turbocharger systems, ensuring the stable and efficient operation of the turbocharger’s internal components. Its proper function is essential for the longevity and performance of the turbocharger in diverse engine applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.