This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3532217 Thrust Collar is a component designed to facilitate the smooth operation of heavy-duty truck engines. Its role is significant in maintaining the efficiency and reliability of the engine’s mechanical system. Understanding its function and importance can help in the proper maintenance and operation of heavy-duty trucks.

Basic Concepts of Thrust Collars

A thrust collar is a mechanical component that helps manage axial loads within an engine. It operates by providing a surface against which other moving parts can press, thereby controlling the movement and positioning of these parts. In an engine, the thrust collar plays a role in ensuring that components such as gears and shafts remain properly aligned and function efficiently 1.

Purpose of the 3532217 Thrust Collar

The 3532217 Thrust Collar is specifically designed to interact with other engine components to manage axial loads. It helps in maintaining the proper alignment and operation of the crankshaft and other moving parts within the engine. By doing so, it contributes to the overall stability and performance of the engine 2.

Key Features

The 3532217 Thrust Collar is constructed from high-quality materials that offer durability and resistance to wear. Its design includes precise machining to ensure a proper fit and function within the engine. Additionally, it may feature specific surface treatments or coatings to enhance its performance and longevity.

Benefits

The use of the 3532217 Thrust Collar can lead to improved engine performance by ensuring that components operate within their designed parameters. Its durable construction contributes to the overall reliability of the engine, reducing the likelihood of unexpected failures. Additionally, proper use of this component can enhance the efficiency of the engine, leading to better fuel economy and reduced maintenance costs 3.

Installation Process

Installing the 3532217 Thrust Collar requires careful attention to detail. The process involves cleaning the mating surfaces, aligning the collar correctly within the engine, and securing it in place. Using the appropriate tools and following manufacturer guidelines ensures that the collar is installed correctly and functions as intended.

Troubleshooting

Common issues with the 3532217 Thrust Collar may include wear or damage due to improper installation or operation. Symptoms to watch for include unusual engine noises, reduced performance, or increased wear on other components. Troubleshooting steps may involve inspecting the collar for signs of damage, ensuring proper alignment, and replacing the collar if necessary.

Maintenance Tips

To ensure the longevity and optimal performance of the 3532217 Thrust Collar, regular inspections are recommended. This includes checking for signs of wear or damage and ensuring that all components are properly aligned and secured. Following manufacturer guidelines for maintenance intervals and procedures can help prevent issues and extend the life of the collar.

Compatibility and Applications

The 3532217 Thrust Collar is designed for use in specific types of engines and truck models. Its application is determined by the engine’s design and the requirements of the vehicle. Understanding the compatibility of this component with your engine is important for ensuring proper function and performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins plays a significant role in the automotive and heavy-duty truck industry, providing reliable and efficient power solutions for a wide range of applications.

Cummins Engine Compatibility with Thrust Collar Part 3532217

The Thrust Collar part 3532217, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is essential for maintaining the alignment and stability of the crankshaft within the engine block, ensuring smooth operation and longevity of the engine. Below is a detailed description of the compatibility of this thrust collar with various Cummins engines.

4B3.9, 6B5.9, 6C8.3, B6.7 CM2350 B135B, B6.7S, C GAS PLUS CM556, C8.3 G, G8.3, GTA8.3 CM558

The Thrust Collar part 3532217 is compatible with the older generation Cummins engines such as the 4B3.9, 6B5.9, and 6C8.3. These engines are known for their robust design and are often used in heavy-duty applications. The part also fits the B6.7 CM2350 B135B, B6.7S, C GAS PLUS CM556, C8.3 G, G8.3, and GTA8.3 CM558 engines, which are part of the B-Series and C-Series engines. These engines are widely used in various industries, including construction, agriculture, and marine.

ISB (Chrysler), ISB CM2150, ISB CM550, ISB CM850, ISB/ISD6.7 CM2150 SN, ISB5.9 CM2880 B110, ISB5.9 CM2880 B127, ISB6.7 CM2250, ISB6.7 CM2350 B101

The ISB engines, including the ISB (Chrysler), ISB CM2150, ISB CM550, ISB CM850, ISB/ISD6.7 CM2150 SN, ISB5.9 CM2880 B110, ISB5.9 CM2880 B127, ISB6.7 CM2250, and ISB6.7 CM2350 B101, are part of the Cummins ISB family. These engines are designed for high performance and efficiency, making them suitable for a wide range of applications, from on-highway to off-highway use. The Thrust Collar part 3532217 is engineered to fit these engines, ensuring proper crankshaft alignment and reducing wear and tear.

ISBE CM2150, ISBE CM800, ISBE4 CM850, ISC CM2150, ISC CM554, ISC CM850, ISC8.3 CM2250

The ISBE and ISC engines, such as the ISBE CM2150, ISBE CM800, ISBE4 CM850, ISC CM2150, ISC CM554, ISC CM850, and ISC8.3 CM2250, are part of the Cummins B-Series and C-Series engines. These engines are known for their durability and reliability, making them ideal for heavy-duty applications. The Thrust Collar part 3532217 is designed to fit these engines, providing the necessary support and stability to the crankshaft, which is crucial for maintaining engine performance and longevity.

Role of Part 3532217 Thrust Collar in Engine Systems

The 3532217 Thrust Collar is an integral component in various engine systems, ensuring the smooth operation and longevity of the engine. Here’s how it interfaces with several key components:

Core Assemblies and Heat Exchangers

- Core Assembly Heat Exchanger 35 and 35W: The thrust collar works in conjunction with these assemblies to maintain proper alignment and reduce friction between moving parts. This ensures efficient heat transfer and prolongs the life of the heat exchanger.

- H1E Core Assembly: In this setup, the thrust collar helps in stabilizing the rotor assembly, which is vital for the consistent performance of the heat exchanger.

Turbocharger Systems

- Turbocharger and Turbocharger Actuator: The thrust collar is essential in these systems for managing the axial loads on the turbocharger rotor. It ensures that the rotor remains securely in place, preventing undue wear and potential failure.

- Turbocharger Campaign Kit and Core Repair Kit: When performing repairs or upgrades, the thrust collar plays a role in reassembling the turbocharger, ensuring that all components are correctly aligned and balanced.

Engine and Exhaust Components

- Engine Installation Kit and Engine Piston Kit: During engine installation or overhaul, the thrust collar assists in the precise alignment of the piston and other moving parts, contributing to the engine’s overall efficiency and reliability.

- Exhaust Manifold Kit: The thrust collar indirectly supports the exhaust system by ensuring that the turbocharger, to which the exhaust manifold is often connected, operates smoothly without excessive movement or wear.

Fuel System Components

- Fuel Injection Pump and Fuel Pump Coupling: Although not directly connected, the stable operation of the engine, facilitated by the thrust collar, ensures that the fuel system components deliver fuel efficiently and consistently.

Service and Incomplete Turbocharger Kits

- Service Kit and Incomplete Turbocharger Kit: These kits often include the thrust collar as a replacement part. Its role in these kits is to restore the turbocharger’s operational integrity, ensuring that all components function as intended.

In summary, the 3532217 Thrust Collar is a key component in maintaining the alignment and operational efficiency of various engine and turbocharger systems. Its proper function is essential for the reliable performance of these complex assemblies.

Conclusion

The 3532217 Thrust Collar plays a crucial role in the efficient and reliable operation of Cummins engines. By managing axial loads and ensuring proper alignment of critical components, it contributes to the overall performance and longevity of the engine. Regular maintenance and proper installation are essential to maximize the benefits of this component.

-

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Cummins Inc. Service Manual (5411247). Cummins Inc., 2023.

↩

SPECIFICATIONS

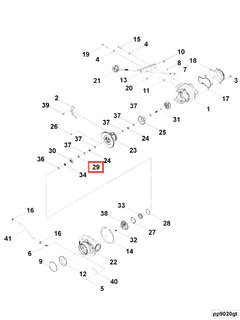

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Turbocharger Bearing | 2 | 3503100 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.