3558828

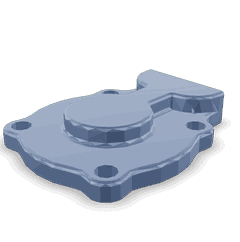

Unloading Valve Body

Cummins®

IN STOCK

3 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3558828 Unloading Valve Body is a component designed for use in commercial trucks, specifically within their hydraulic systems. Its purpose is to regulate hydraulic pressure, ensuring the system operates efficiently and safely. The significance of this part lies in its ability to maintain optimal pressure levels, which is vital for the performance and longevity of the truck’s hydraulic components 1.

Basic Concepts of Unloading Valve Body

An Unloading Valve Body functions within hydraulic systems to manage and regulate pressure. It operates on the principle of diverting excess hydraulic fluid back to the reservoir when pressure exceeds a predetermined threshold. This mechanism prevents over-pressurization, which could lead to system damage or failure. The valve body plays a role in maintaining system stability and efficiency by ensuring that pressure levels remain within safe operating limits 2.

Purpose and Function

The Cummins 3558828 Unloading Valve Body is integral to the operation of a truck’s hydraulic system. It manages hydraulic pressure by redirecting excess fluid, thus preventing system over-pressurization. This function is crucial for the efficient operation of hydraulic components, such as brakes and steering systems, ensuring they perform reliably under varying conditions. The valve body contributes to the overall system performance by maintaining consistent pressure levels, which is essential for the smooth operation of the truck 3.

Key Features

The Cummins 3558828 Unloading Valve Body is characterized by its robust design and the use of high-quality materials, which enhance its performance and durability. Key features include precision engineering for accurate pressure regulation, corrosion-resistant materials to withstand harsh operating environments, and a compact design that facilitates easy integration into existing hydraulic systems. These features collectively contribute to the valve body’s reliability and efficiency in commercial truck applications.

Benefits

The incorporation of the Cummins 3558828 Unloading Valve Body into a truck’s hydraulic system offers several advantages. It improves system efficiency by ensuring optimal pressure levels, which can lead to enhanced performance of hydraulic components. Additionally, the valve body’s design and materials contribute to reduced maintenance requirements, as it is built to withstand the rigors of commercial use. The overall performance of the truck’s hydraulic system is enhanced, leading to more reliable operation and potentially lower operating costs over time.

Installation and Integration

Proper installation and integration of the Cummins 3558828 Unloading Valve Body within a truck’s hydraulic system are crucial for its effective operation. It is important to follow manufacturer guidelines for installation to ensure compatibility and optimal performance. Considerations should include proper alignment, secure mounting, and verification of system compatibility. Careful attention to these details during installation will help ensure the valve body functions as intended within the hydraulic system.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are key to ensuring the longevity and efficiency of the Cummins 3558828 Unloading Valve Body. Common issues may include pressure inconsistencies or leaks, which can often be addressed through routine checks and maintenance. Recommended practices include regular inspection for wear or damage, ensuring all connections are secure, and monitoring system pressure levels. Adhering to these maintenance practices will help maintain the valve body’s performance and extend its operational life.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient automotive components. The company’s dedication to advancing technology and meeting the needs of its customers is evident in its extensive product line, which includes components like the Cummins 3558828 Unloading Valve Body.

Compatibility of Cummins Unloading Valve Body Part 3558828

The Cummins Unloading Valve Body part number 3558828 is a critical component in the engine’s exhaust brake system. It is designed to manage the exhaust flow and pressure, ensuring efficient engine braking and performance. This part is compatible with a variety of Cummins engines, grouped as follows:

Small Bore Engines

- 4B3.9

- 6B5.9

- B5.9 G

- QSB5.9 44 CM550

Medium Bore Engines

- 6C8.3

- C8.3 G

- QSC8.3 CM554

Large Bore Engines

- C GAS PLUS CM556

- ISB CM550

- ISC CM554

- ISL CM554

- ISM CM570

- QSM11 CM570

Specialized Engines

- L10 CELECT

- L10 GAS

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

- N14 CELECT PLUS

- N14 MECHANICAL

Industrial Engines

- NH/NT 855

This part is engineered to fit seamlessly into the exhaust systems of these engines, ensuring optimal performance and reliability.

Role of Part 3558828 Unloading Valve Body in Engine Systems

The Part 3558828 Unloading Valve Body is an integral component in various engine systems, particularly within air compressor assemblies and QE unloader service kits. Its primary function is to regulate the unloading process of the compressor, ensuring efficient operation and longevity of the system.

Integration with Air Compressor Systems

In air compressor systems, the Unloading Valve Body works in conjunction with the compressor conversion kit and various head assemblies (such as QE/B, QE/C, QE/M, and QE/STD head assy kits). It manages the transition between loaded and unloaded states of the compressor. This regulation helps in maintaining optimal pressure levels, reducing wear and tear on the compressor components, and enhancing overall system performance.

Function within QE Unloader Service Kits

The QE Unloader Service Kits, which include components like the QE Unloader SER and QE Unloader SERV assemblies, rely on the Unloading Valve Body to facilitate smooth operation. By accurately controlling the unloading process, it prevents sudden pressure spikes that could damage the compressor or other connected components. This precise control is essential for the reliable functioning of the QE component service kits, ensuring that the compressor operates within safe parameters.

Contribution to System Efficiency

The Unloading Valve Body’s role extends to improving the efficiency of the entire system. By effectively managing the unloading cycles, it helps in reducing energy consumption and enhancing the compressor’s operational lifespan. This is particularly beneficial in high-demand environments where the compressor is frequently cycled on and off.

Maintenance and Service

Regular maintenance of the Unloading Valve Body is essential to ensure its continued effective operation. Service kits often include this component to facilitate easy replacement and upkeep. Proper maintenance not only ensures the longevity of the Unloading Valve Body but also contributes to the overall reliability and performance of the engine system.

Conclusion

The Cummins 3558828 Unloading Valve Body is a key element in the efficient and reliable operation of air compressor and QE unloader service systems. Its role in regulating the unloading process is vital for maintaining system performance, reducing wear, and ensuring safe operation. Regular maintenance and proper integration are essential for maximizing the benefits of this part in commercial truck applications.

-

Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines, Hua Zhao, CRC Press, 2010

↩ -

A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition, Allan Bonnick and Derek Newbold, Elsevier Ltd, 2011

↩ -

An Introduction to Modern Vehicle Design, Julian Happian-Smith, Butterworth-Heinemann, 2002

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.