This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

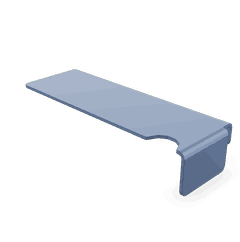

The Cummins 3606670 Heat Shield is a component designed to manage and mitigate heat in commercial trucks. Its purpose is to protect various parts of the vehicle from excessive heat generated during operation, ensuring the longevity and efficiency of the truck’s systems.

Basic Concepts of Heat Shields

A heat shield is a protective barrier that reduces the transfer of heat from high-temperature areas to other parts of a vehicle. It functions by reflecting and dissipating heat, thereby maintaining optimal operating temperatures for sensitive components. Heat shields are typically made from materials such as aluminum, stainless steel, or high-temperature alloys, chosen for their heat resistance and durability 1.

Purpose of the Cummins 3606670 Heat Shield

The Cummins 3606670 Heat Shield plays a specific role in the operation of a truck by protecting certain areas and components from excessive heat. It is positioned to shield parts such as the engine block, exhaust system, and nearby wiring harnesses. By doing so, it helps maintain the integrity and performance of these components, preventing heat-related damage and ensuring reliable operation.

Key Features

The Cummins 3606670 Heat Shield is designed with several features that enhance its performance. It is constructed from high-quality materials that offer excellent heat resistance. The shield’s shape is engineered to provide maximum coverage and protection for the targeted areas. Additionally, it may include unique attributes such as heat-reflective coatings or reinforced edges to improve its effectiveness.

Benefits of Using the Cummins 3606670 Heat Shield

Using the Cummins 3606670 Heat Shield offers several advantages. It contributes to improved safety by reducing the risk of heat-related failures. The shield also enhances the durability of nearby components by preventing heat damage, which can extend the lifespan of the truck’s systems. Furthermore, by maintaining optimal temperatures, the heat shield can contribute to increased operational efficiency 2.

Installation Considerations

When installing the Cummins 3606670 Heat Shield, it is important to follow guidelines and best practices to ensure proper functionality. This includes positioning the shield correctly to cover the intended areas and securing it in place using appropriate methods. Prerequisites for installation may include ensuring the area is clean and free from obstructions to allow for effective heat management.

Troubleshooting and Maintenance

Common issues with heat shields may include damage from physical impact or degradation over time. Troubleshooting steps involve inspecting the shield for signs of wear or damage and addressing any issues promptly. Maintenance tips include regular checks for proper positioning and securing, as well as cleaning the shield to remove any debris that may affect its performance.

Regulatory and Safety Standards

Heat shields in commercial trucks are subject to regulatory standards and safety certifications to ensure they meet specific performance and safety criteria. The Cummins 3606670 Heat Shield complies with these standards, demonstrating its adherence to industry requirements for heat management and protection.

Compatibility with Cummins Engines

This Cummins part is designed to fit a variety of Cummins engines, providing thermal protection and reducing heat transfer in critical areas. It is compatible with engines such as the ISM CM570, QSM11 CM570, ISM11 CM876 SN, M11 series (M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL), and L10 GAS. By fitting this part, these engines can operate more efficiently, with reduced risk of overheating and related damage 3.

Role of 3606670 Heat Shield in Engine Systems

This part is an essential component in managing thermal conditions within various engine systems. It is strategically positioned to protect adjacent components from excessive heat generated by the engine.

Integration with Oil Cooler

In systems equipped with an oil cooler, the heat shield plays a significant role. The oil cooler is designed to regulate the temperature of the engine oil, ensuring it remains within optimal operating ranges. The heat shield is placed near the oil cooler to prevent heat transfer to nearby components, maintaining the efficiency of the oil cooling process. This protection helps in preserving the integrity of the oil cooler and enhances the overall performance of the engine by ensuring that the oil remains at the correct temperature.

Interaction with Water Plumbing

The heat shield also interacts with the water plumbing system of the engine. The water plumbing, which includes hoses, pipes, and the water pump, is responsible for circulating coolant throughout the engine to manage its temperature. The heat shield is positioned to shield these components from direct heat exposure, which can otherwise lead to degradation of hoses, warping of pipes, and inefficient operation of the water pump. By maintaining a stable environment around the water plumbing, the heat shield contributes to the consistent and reliable operation of the cooling system.

Overall Thermal Management

Beyond specific components, the heat shield aids in the overall thermal management of the engine. It helps in creating a controlled thermal environment, reducing the risk of heat-related damage to sensitive engine parts. This not only enhances the durability of the engine but also contributes to its efficient operation under various conditions.

The effective use of the heat shield in conjunction with the oil cooler and water plumbing demonstrates its importance in maintaining the intricate balance of temperatures within the engine system.

Conclusion

The Cummins 3606670 Heat Shield is a vital component in the thermal management of commercial trucks. By protecting critical engine components from excessive heat, it ensures the longevity, safety, and efficiency of the vehicle’s systems. Proper installation, regular maintenance, and adherence to regulatory standards are essential for maximizing the benefits of this part.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ -

Fuel Consumption and Consumption Optimization, Second Edition, Michael Hilgers, Springer Nature, 2023

↩ -

Automotive Technician Training, Second Edition, Tom Denton and Hayley Pells, Routledge, 2022

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.