This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

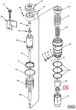

The Cummins Injector Cup (Part #3609797) is a component designed to facilitate the operation of fuel injectors in heavy-duty trucks. Its role is to ensure the proper functioning of the fuel injection system by maintaining fuel pressure and providing a secure seal for the injector. This Cummins part is integral to the efficient and reliable performance of Cummins engines, contributing to their reputation for durability and power 3.

Function and Operation

The Injector Cup operates within the fuel injection system by housing the fuel injector and creating a seal that prevents fuel leakage. It plays a role in maintaining consistent fuel pressure, which is vital for the precise delivery of fuel to the engine’s combustion chambers. The cup’s design allows it to withstand the high pressures and temperatures associated with diesel fuel injection, ensuring that the injector functions correctly under various operating conditions 1.

Key Features

The Cummins Injector Cup is characterized by its robust design and material composition. It is constructed from high-quality materials that offer durability and resistance to the high pressures and temperatures encountered in diesel engines. The cup’s design ensures compatibility with Cummins engines, providing a reliable seal that contributes to the overall efficiency and performance of the fuel injection system 2.

Benefits

The use of the Cummins Injector Cup offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered under consistent pressure, which enhances combustion efficiency. Additionally, the cup helps to maintain engine performance by providing a secure seal that prevents fuel leaks. This not only protects the engine from potential damage but also reduces the risk of environmental contamination from fuel spills 3.

Installation and Maintenance

Proper installation of the Injector Cup is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure a secure fit and proper sealing. Regular maintenance, including inspection for wear or damage, is recommended to prevent issues such as leaks or performance decline. Following the manufacturer’s maintenance schedule can help extend the life of the Injector Cup and maintain engine efficiency 1.

Troubleshooting Common Issues

Common issues associated with injector cups may include leaks or a decline in engine performance. These problems can often be traced back to wear, damage, or improper installation. Diagnostic procedures may involve inspecting the cup for signs of wear, checking the seal integrity, and ensuring that the injector is correctly seated. Repair or replacement of the Injector Cup may be necessary to resolve these issues and restore engine performance 2.

Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a strong reputation in the heavy-duty truck industry, Cummins is known for producing reliable and high-performance engines. The company’s commitment to quality and customer satisfaction is reflected in its extensive product range and the durability of its components, such as the Injector Cup 3.

Conclusion

The Cummins Injector Cup (Part #3609797) is a critical component in the fuel injection system of Cummins engines. Its robust design and material composition ensure durability and resistance to high pressures and temperatures. The Injector Cup contributes to improved fuel efficiency, maintains engine performance, and prevents fuel leaks, making it an essential part of the engine’s fuel delivery system. Proper installation and regular maintenance are key to ensuring the longevity and efficiency of this Cummins part.

-

Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Ben Watson, Cengage Learning, 2011.

↩ ↩ -

Heavy Duty Truck Systems, Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011.

↩ ↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.