This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3633178 Tube Connector is a specialized component designed for use in commercial truck systems. Tube connectors serve as links in fluid systems, facilitating the transfer of various fluids such as fuel, coolant, or hydraulic fluid between different parts of the system. This part plays a role in ensuring the efficient and reliable operation of these systems by providing a secure and leak-free connection.

Basic Concepts of Tube Connectors

Tube connectors are designed to join tubes and other components in fluid systems, ensuring a tight seal and maintaining the integrity of the system. These connectors are typically made from durable materials such as brass, stainless steel, or high-grade plastics, chosen for their resistance to corrosion and ability to withstand high pressures and temperatures 1. The design of tube connectors varies depending on the specific application, but they generally feature threaded or compression fittings to ensure a secure connection. Proper sealing and connection integrity are vital in fluid systems to prevent leaks, maintain system pressure, and ensure the efficient transfer of fluids.

Purpose of the 3633178 Tube Connector

The Cummins 3633178 Tube Connector is designed to connect specific systems within a truck, handling various fluids essential for the vehicle’s operation. It plays a role in linking components within the fuel, coolant, or hydraulic systems, ensuring that fluids are transferred efficiently and without leakage. By providing a reliable connection point, the 3633178 Tube Connector contributes to the overall performance and reliability of the truck’s fluid systems.

Key Features

The Cummins 3633178 Tube Connector boasts several key features that enhance its performance and durability. It is constructed from high-quality materials resistant to corrosion and capable of withstanding the pressures and temperatures encountered in commercial truck applications. The connector features a precise design that ensures a secure fit and leak-free operation. Additionally, it may include unique attributes such as reinforced seals or specialized coatings to further improve its performance in demanding environments.

Benefits

Using the Cummins 3633178 Tube Connector offers several benefits. It contributes to improved system efficiency by ensuring a secure and leak-free connection, which helps maintain system pressure and fluid flow. The connector’s reliable design enhances the overall reliability of the truck’s fluid systems, reducing the risk of downtime due to leaks or failures. Ease of installation is another advantage, as the connector is designed for straightforward fitting into the system. Moreover, its durable construction and resistance to corrosion make it a low-maintenance component, contributing to the truck’s longevity 2.

Installation Considerations

When installing the Cummins 3633178 Tube Connector, it is important to follow guidelines and best practices to ensure a secure and leak-free connection. Proper torque specifications should be adhered to when tightening the connector to avoid over-tightening, which can damage the fitting, or under-tightening, which can lead to leaks. Alignment is crucial; the connector should be properly aligned with the tubes it is joining to ensure a smooth and efficient fluid transfer. Sealing techniques, such as the use of thread sealant or compression fittings, should be employed as recommended to enhance the integrity of the connection.

Troubleshooting Common Issues

Common problems associated with tube connectors include leaks, corrosion, and improper connections. To troubleshoot these issues, first, inspect the connector and surrounding components for signs of damage or wear. Check for proper alignment and ensure that the connector is tightened to the correct torque specifications. If a leak is detected, verify the integrity of the seals and consider reapplying thread sealant or replacing damaged components. Corrosion can often be addressed by cleaning the affected areas and applying a corrosion-resistant coating. Improper connections may require realigning the components or replacing the connector if it is damaged.

Maintenance Tips

Regular maintenance of the Cummins 3633178 Tube Connector is key to ensuring optimal performance and longevity. Inspection intervals should be established based on the truck’s usage and operating conditions, with more frequent checks for vehicles operating in harsh environments. Cleaning the connector and surrounding components can help prevent corrosion and ensure a secure fit. When signs of wear or damage are detected, such as leaks or corrosion, the connector should be repaired or replaced to maintain system integrity. Following these maintenance tips will help ensure the reliable operation of the truck’s fluid systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for its commitment to quality and innovation. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications. Cummins’ dedication to excellence is evident in its manufacturing processes, which emphasize precision, durability, and performance, ensuring that its components, including the 3633178 Tube Connector, deliver reliable service in the field 3.

Compatibility with Cummins Engines

The Tube Connector part number 3633178, manufactured by Cummins, is designed to integrate seamlessly with several Cummins engine models. This part is essential for maintaining the structural integrity and operational efficiency of the engine by ensuring proper fluid flow and pressure management.

K38 and K50 Engines

For the K38 and K50 engines, the Tube Connector 3633178 is a critical component that fits into the engine’s design to facilitate the connection between various fluid lines. These engines, known for their robust performance and reliability, benefit from the precision engineering of this connector. The part’s design ensures a secure and leak-proof connection, which is vital for the engine’s overall functionality.

The Tube Connector 3633178 is engineered to withstand the high pressures and temperatures typical in these engines, ensuring longevity and consistent performance. Its compatibility with the K38 and K50 engines underscores Cummins’ commitment to providing high-quality, durable parts that enhance engine performance and reliability.

Role of the 3633178 Tube Connector in Engine Systems

The 3633178 Tube Connector is an essential component in the integration and functionality of various engine systems. Its primary role is to facilitate secure and efficient connections between different parts of the engine, ensuring optimal performance and reliability.

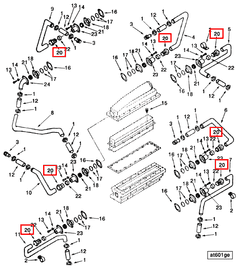

Integration with Aftercooler Mounting

In systems where aftercoolers are utilized, the 3633178 Tube Connector plays a significant role. It ensures a tight and leak-proof connection between the aftercooler and the surrounding components. This is vital for maintaining the efficiency of the aftercooler, which is responsible for cooling the compressed air from the turbocharger before it enters the engine. A secure connection prevents any loss of pressure and ensures that the aftercooler operates within its designed parameters.

Connection to Performance Parts

When it comes to performance parts, the 3633178 Tube Connector is often used to link high-flow intercoolers, turbochargers, and other performance-enhancing components. Its robust design allows it to handle increased air flow and pressure, which are common in performance-tuned engines. This ensures that all performance parts work in unison, maximizing the engine’s potential without compromising safety or efficiency.

Plumbing Applications

In the context of engine plumbing, the 3633178 Tube Connector is invaluable. It is used to connect various hoses and pipes that transport fluids such as coolant, oil, and fuel throughout the engine system. Its design allows for easy installation and removal, which is particularly useful during maintenance or upgrades. Additionally, it provides a secure seal that prevents leaks, which could lead to engine damage or reduced performance.

Aftercooler Water System

For engines equipped with an aftercooler water system, the 3633178 Tube Connector is used to connect the water lines to the aftercooler. This ensures that the water flow is consistent and unrestricted, which is essential for effective cooling. Proper cooling is necessary to prevent overheating and to maintain the engine’s efficiency and longevity.

Protective Cover Applications

In some engine designs, the 3633178 Tube Connector is also used in conjunction with protective covers. These covers are designed to shield sensitive components from debris, extreme temperatures, and other environmental factors. The tube connector ensures that the protective covers are securely attached, providing an additional layer of security and durability to the engine system.

Conclusion

Overall, the 3633178 Tube Connector is a versatile and reliable component that enhances the functionality and performance of various engine systems. Its ability to provide secure, leak-proof connections makes it an indispensable part in the maintenance and upgrade of modern engines.

-

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩ -

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.