This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

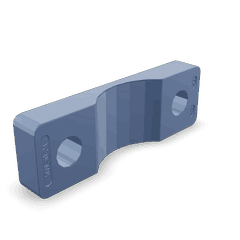

The Cummins 3636628 Wear Pad is a component designed to enhance the operational efficiency and longevity of commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of Wear Pads

Wear pads are components used in mechanical systems to reduce friction and wear between moving parts. They are typically made from materials that can withstand high levels of stress and abrasion. In applications such as commercial trucks, wear pads play a role in protecting critical components from damage, thereby extending the lifespan of the machinery and reducing the frequency of required maintenance 1.

Purpose of the Cummins 3636628 Wear Pad

The Cummins 3636628 Wear Pad is designed to operate within the mechanical system of a truck, specifically to mitigate wear and tear on adjacent components. By providing a sacrificial surface that absorbs friction and impact, this wear pad helps maintain the integrity of more complex and costly parts, ensuring smoother operation and potentially reducing downtime.

Key Features

This Cummins part is characterized by its robust material composition, which is engineered to endure the harsh conditions typical of commercial truck operations. Its design incorporates features that enhance its durability and effectiveness, such as a precise fit that ensures optimal performance within the truck’s mechanical system.

Benefits

The advantages of the Cummins 3636628 Wear Pad include improved durability, which contributes to the overall reliability of the truck. It also reduces the need for frequent maintenance, as its presence helps protect other components from premature wear. Additionally, the wear pad enhances operational efficiency by ensuring that the mechanical system operates smoothly, which can lead to better fuel economy and performance 2.

Installation Considerations

Proper installation of the Cummins 3636628 Wear Pad is important to ensure its effectiveness. This process may involve preparatory steps such as cleaning the installation area and inspecting other components for wear or damage. The use of appropriate tools and following manufacturer guidelines can help achieve a secure and proper fit, maximizing the wear pad’s performance.

Troubleshooting Common Issues

Frequent problems associated with wear pads can include premature wear, misalignment, or failure to adequately protect adjacent components. Diagnosing these issues may involve inspecting the wear pad for signs of damage or excessive wear, as well as examining the condition of nearby parts. Resolving these issues often requires replacing the wear pad and, in some cases, addressing underlying problems within the mechanical system.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3636628 Wear Pad, regular maintenance practices are recommended. This includes periodic inspections for signs of wear or damage, cleaning the area around the wear pad to prevent contamination, and replacing the pad according to the manufacturer’s guidelines or as needed based on the condition of the truck’s mechanical system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles 3.

Cummins Engine Part 3636628: Wear Pad Compatibility

The Cummins part number 3636628, identified as a Wear Pad, is designed to fit a variety of Cummins engines. This wear pad is a critical component that ensures the longevity and efficiency of the engine by reducing wear and tear on specific parts. Below is a detailed breakdown of the engines with which this wear pad is compatible.

K50 Series

- K50

- The K50 engine series benefits from the wear pad in maintaining the integrity of its components, ensuring smooth operation and reducing maintenance needs.

KTA38 Series

- KTA38GC CM558

- The KTA38GC CM558 engine utilizes the wear pad to protect critical areas from excessive wear, contributing to the engine’s durability and performance.

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

- Both the QSK38 CM2150 MCRS and QSK38 CM850 MCRS engines incorporate the wear pad to enhance operational efficiency and reduce wear on specific parts.

QSK50 Series

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- The QSK50 series engines, including the QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK50 CM2350 K108, all utilize the wear pad to ensure that moving parts operate smoothly and with minimal friction.

QSK60 Series

- QSK60 CM850 MCRS

- The QSK60 CM850 MCRS engine also relies on the wear pad to maintain the performance and longevity of its components.

QSK78 Series

- QSK78 CM500

- The QSK78 CM500 engine incorporates the wear pad to protect against wear and tear, ensuring reliable operation.

QSK95 Series

- QSK95 CM2350 K111

- QSK95 CM2350 K113

- The QSK95 series engines, specifically the QSK95 CM2350 K111 and QSK95 CM2350 K113, use the wear pad to enhance durability and reduce maintenance requirements.

By ensuring that the wear pad is correctly installed and maintained, operators can significantly extend the lifespan of these engines and maintain their performance.

Role of Part 3636628 Wear Pad in Engine Systems

The 3636628 Wear Pad is an essential component in the operation of various engine systems, particularly those involving fluid dynamics and thermal management. Its primary function is to mitigate wear and tear on moving parts, ensuring longevity and efficiency of the system.

In the auxiliary cooling system, the Wear Pad plays a significant role by reducing friction between the moving parts of the system. This is particularly important in the manifold where different fluid pathways converge and diverge. The Wear Pad ensures smooth operation by preventing metal-to-metal contact, which can lead to increased wear and potential system failure.

Within the water system, the Wear Pad is utilized in areas where water flow is turbulent or where components experience high levels of stress. For instance, in the water bypass tube and water transfer tube, the Wear Pad helps in maintaining the integrity of the tube walls by absorbing vibrations and reducing the impact of water flow.

Conclusion

In summary, the 3636628 Wear Pad is a vital component in enhancing the durability and performance of engine systems by providing necessary protection against wear in high-stress areas. Proper installation, maintenance, and understanding of its role within the engine system are crucial for maximizing its benefits and ensuring the longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.