This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

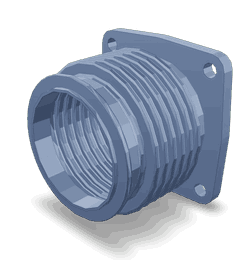

The Expansion Bellows 3637928, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the automotive and heavy-duty truck industries, produces this bellows to address specific operational needs in truck systems. Expansion bellows play a role in accommodating thermal expansion and contraction within various systems, ensuring the integrity and efficiency of the components they connect.

Basic Concepts of Expansion Bellows

Expansion bellows are flexible elements used in systems where components undergo thermal expansion and contraction. They function by allowing for movement and flexibility between connected parts, thereby maintaining system integrity under varying temperatures. These bellows are typically constructed from materials such as stainless steel, which offer durability, resistance to corrosion, and the ability to withstand high temperatures. The choice of material is crucial for ensuring the bellows can perform reliably in demanding environments 1.

Purpose of Expansion Bellows 3637928 in Truck Operations

The Expansion Bellows 3637928 is designed to play a specific role in the operation of commercial trucks. It contributes to the efficiency and reliability of truck systems by accommodating the thermal expansion and contraction of connected components. This function helps prevent stress and potential damage to the system, ensuring smooth operation and longevity of the truck’s components.

Key Features of Expansion Bellows 3637928

The Expansion Bellows 3637928 boasts several key features that enhance its performance and durability. Its design incorporates multiple convolutions, which provide the necessary flexibility and accommodate significant movement. The bellows is constructed from high-quality stainless steel, ensuring resistance to corrosion and high-temperature environments. Additionally, it features precise engineering to ensure a secure fit and optimal performance within the truck’s system.

Benefits of Using Expansion Bellows 3637928

Incorporating the Expansion Bellows 3637928 into truck systems offers several advantages. It contributes to improved system longevity by reducing stress on connected components. The bellows also helps minimize maintenance needs by accommodating thermal expansion and contraction, which can otherwise lead to system failures. Furthermore, its use enhances operational efficiency by ensuring components remain securely connected and functioning optimally under varying temperatures.

Installation Considerations

When installing the Expansion Bellows 3637928, it is important to follow guidelines and best practices to ensure proper integration into the truck’s system. Preparatory steps include ensuring the connected components are clean and free from debris. The use of appropriate tools is necessary to secure the bellows in place without damaging it. Common pitfalls to avoid during installation include over-tightening, which can compromise the bellows’ flexibility, and improper alignment, which can lead to system inefficiencies.

Troubleshooting Common Issues

Common problems associated with expansion bellows, such as leaks or reduced flexibility, can often be traced back to installation errors or environmental factors. Troubleshooting steps may include inspecting the bellows for signs of wear or damage, ensuring it is properly aligned and secured, and checking for any external factors that may be affecting its performance. Regular inspections and maintenance are vital for identifying issues early and ensuring the bellows continues to function effectively.

Maintenance Tips

Ongoing maintenance of the Expansion Bellows 3637928 is key to ensuring optimal performance and longevity. This includes regular cleaning to remove any buildup that could affect its flexibility or sealing capabilities. Inspection routines should be established to check for signs of wear, corrosion, or damage. When considering replacement, it is important to assess the bellows’ condition against its operational requirements and environmental exposure.

Cummins: A Brief Overview

Cummins Inc. is a leader in the automotive and heavy-duty truck industries, known for its commitment to innovation and quality. With a rich history of producing reliable and high-performance components, Cummins offers a wide range of products designed to meet the demanding needs of commercial vehicles. The company’s dedication to advancing technology and improving efficiency is evident in its product lineup, which includes the Expansion Bellows 3637928 2.

Cummins Expansion Bellows Part 3637928

The Cummins Expansion Bellows part number 3637928 is a critical component designed to accommodate thermal expansion and contraction in various Cummins engine models. This part is integral to maintaining the integrity and performance of the engine by allowing for the necessary movement without compromising the engine’s sealing and structural integrity.

Application in Cummins Engines

QSK50 CM2350 K108 and QSK78 CM500

The Expansion Bellows part 3637928 is specifically engineered to fit into the engine architecture of the QSK50 CM2350 K108 and QSK78 CM500 engines. These engines are known for their robust design and high performance, often used in heavy-duty applications such as marine and industrial settings. The bellows are strategically placed to manage the thermal stresses that occur during engine operation, ensuring that the engine components remain aligned and sealed effectively.

Compatibility and Installation

When installing the Expansion Bellows part 3637928 in these engines, it is essential to follow the manufacturer’s guidelines to ensure proper fit and function. The bellows must be correctly aligned with the mating surfaces to prevent leaks and maintain the engine’s operational efficiency. Technicians should also verify that the bellows is not damaged during installation and that it is securely fastened to avoid any potential failure points.

Maintenance and Inspection

Regular inspection of the Expansion Bellows is crucial to maintaining engine performance. Technicians should check for signs of wear, such as cracks or excessive deformation, which could indicate that the bellows need to be replaced. Proper maintenance of this component can extend the lifespan of the engine and prevent costly downtime due to unexpected failures.

Role of Part 3637928 Expansion Bellows in Engine Systems

The Expansion Bellows (part 3637928) is an essential component in the arrangement of various engine systems, particularly in the context of the turbocharger.

In the turbocharger setup, the Expansion Bellows is strategically positioned between the exhaust manifold and the turbine housing. Its primary function is to accommodate the thermal expansion and contraction that occur due to the high temperatures and pressures within the exhaust system. This flexibility helps maintain the integrity of the connection, preventing stress and potential failure of the joints.

Additionally, the Expansion Bellows plays a significant role in reducing vibrations transmitted from the exhaust manifold to the turbocharger. By absorbing these vibrations, it contributes to the overall stability and longevity of the turbocharger assembly.

Furthermore, in the engine arrangement, the Expansion Bellows aids in managing the varying lengths of the exhaust pipes due to thermal expansion. This ensures that the exhaust flow remains consistent, optimizing the performance of the turbocharger and enhancing the engine’s efficiency.

Conclusion

In summary, the incorporation of the Expansion Bellows (part 3637928) in the engine systems, especially within the turbocharger arrangement, is vital for maintaining structural integrity, reducing vibrations, and ensuring consistent exhaust flow. Regular maintenance and proper installation are key to maximizing the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.