This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3641239 Shock Absorber is engineered for commercial trucks, aiming to enhance the suspension system by managing spring oscillations. This contributes to a smoother ride, improved vehicle control, and enhanced overall performance, especially under varying load conditions and road surfaces 1.

Basic Concepts of Shock Absorbers

Shock absorbers are vital for vehicle suspension systems, designed to dampen spring oscillations caused by road irregularities. They convert kinetic energy into heat, maintaining tire contact with the road, which is essential for steering, braking, and vehicle stability 2.

Role of the 3641239 Shock Absorber in Truck Operation

This Cummins part is crucial for managing spring oscillations in commercial trucks, contributing to ride comfort by reducing road irregularity impacts on occupants. It also enhances vehicle control by ensuring consistent tire contact, crucial for safe maneuvering and braking. The truck’s handling and stability are significantly influenced by the effective operation of this shock absorber 3.

Key Features of the 3641239 Shock Absorber

The 3641239 Shock Absorber features advanced technology for efficient damping, constructed with durable materials resistant to harsh conditions. Its precision engineering and high-quality components ensure reliable performance under demanding conditions 4.

Benefits of Using the 3641239 Shock Absorber

Utilizing this shock absorber improves handling through consistent tire contact, enhances safety with increased vehicle stability, and offers enhanced comfort by dampening road irregularities. It also potentially increases fuel efficiency by maintaining optimal tire contact 5.

Troubleshooting Common Issues with Shock Absorbers

Common issues with shock absorbers include leaks, unusual noises, and decreased performance. Diagnostic steps involve visual inspections, listening for noises, and assessing ride quality. Promptly addressing these issues prevents more significant problems 6.

Maintenance Tips for Shock Absorbers

Regular maintenance of the 3641239 Shock Absorber is essential for its longevity and optimal performance. This includes regular inspections for wear and tear, ensuring proper lubrication, and compatibility with the vehicle’s suspension system 7.

Cummins: A Brief Overview

Cummins Inc. is renowned in the commercial vehicle industry for its commitment to quality and innovation. Its product range enhances the efficiency, reliability, and performance of commercial vehicles, reflecting its leadership in the industry 8.

Shock Absorber 3641239 Compatibility with Cummins Engines

The 3641239 Shock Absorber is compatible with several Cummins engine models, including the QSK50 CM2150 MCRS, QSK60 CM500, and QSK60 CM850 MCRS. It plays a crucial role in maintaining engine stability and performance by mitigating vibrations and shocks 9.

Installation Considerations

Proper installation of the 3641239 Shock Absorber is vital for enhancing engine performance and lifespan. Following manufacturer guidelines ensures effective reduction of unwanted vibrations and shocks 10.

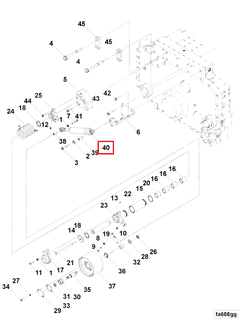

Role of Part 3641239 Shock Absorber in Engine Systems

In engine systems, the 3641239 Shock Absorber is integral to maintaining stability and efficiency. It mitigates vibrations in the Drive system, prolonging component lifespan, and stabilizes the Fan system’s movement, ensuring consistent airflow for effective engine cooling 11.

Conclusion

The Cummins 3641239 Shock Absorber is a critical component for commercial trucks, enhancing ride comfort, vehicle control, and overall performance. Its advanced features, compatibility with various Cummins engines, and the importance of proper maintenance and installation underscore its value in the commercial vehicle industry.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ -

Cummins Inc. (n.d.). Service Manual (5659653).

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ -

Cummins Inc. (n.d.). Service Manual (5659653).

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.