This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3645409 Bellows is a component designed for use in commercial truck operations. Its purpose is to facilitate the connection between various systems or components within the truck, ensuring smooth and efficient operation. This part plays a role in maintaining the integrity and performance of these connections, contributing to the overall reliability and efficiency of the vehicle.

Basic Concepts of Bellows

Bellows are flexible elements used in mechanical systems to connect components that move relative to each other. They operate by accommodating motion, vibration, and misalignment between connected parts, while maintaining a seal to prevent leaks. Commonly constructed from materials such as rubber, metal, or a combination of both, bellows are chosen for their specific properties, including flexibility, durability, and resistance to environmental factors like temperature and pressure variations 1.

Purpose of the 3645409 Bellows in Truck Operations

The 3645409 Bellows serves a specific role in the operation of commercial trucks by connecting systems or components that require flexibility and movement. It facilitates the transfer of fluids, gases, or mechanical motion between parts that may not be perfectly aligned or that move relative to each other. This connection ensures that the systems can operate efficiently without the risk of leaks or damage due to misalignment.

Key Features of the 3645409 Bellows

The design and construction of the 3645409 Bellows include features that enhance its durability, flexibility, and resistance to environmental factors. Its construction materials are selected to withstand the temperature and pressure variations encountered in commercial truck operations. The bellows is engineered to provide a reliable seal and accommodate the necessary movements and vibrations, ensuring long-term performance and reliability.

Benefits of Using the 3645409 Bellows

The advantages of using the 3645409 Bellows include improved performance, reliability, and maintenance ease. By providing a flexible and secure connection between moving parts, it contributes to the overall efficiency and longevity of the truck’s systems. Its design reduces the likelihood of leaks and damage, leading to fewer maintenance requirements and enhanced operational reliability.

Installation and Integration

Proper installation and integration of the 3645409 Bellows within the truck’s systems are crucial for its effective function. Guidelines for installation include ensuring compatibility with other components and adhering to specific requirements to maintain the integrity of the connection. Careful attention to these guidelines ensures that the bellows operates as intended, contributing to the vehicle’s performance and reliability.

Troubleshooting Common Issues

Common problems associated with bellows can include leaks, damage due to wear and tear, or failure to accommodate movement between connected parts. A step-by-step troubleshooting guide can help diagnose and resolve issues related to the 3645409 Bellows, ensuring that any problems are addressed promptly to maintain the efficiency and safety of the truck’s operations.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the 3645409 Bellows. These practices include inspection procedures to check for signs of wear or damage, cleaning methods to remove contaminants that could affect performance, and replacement guidelines to ensure that the bellows is replaced before it fails, maintaining the integrity of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a leader in the commercial truck industry, known for its commitment to innovation, quality, and customer satisfaction. The company designs and manufactures a wide range of automotive components, including the 3645409 Bellows, with a focus on enhancing the performance, reliability, and efficiency of commercial vehicles. Cummins’ dedication to excellence in engineering and manufacturing ensures that its products meet the high demands of the industry.

Bellows Part 3645409 in Cummins Engines

The Bellows part 3645409, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to provide flexibility and durability, ensuring that the engine operates smoothly and efficiently.

QSK50 CM2350 K108

In the QSK50 CM2350 K108 engine, the Bellows part 3645409 plays a vital role in maintaining the integrity of the engine’s sealing system. It is strategically placed to accommodate the natural movements and vibrations that occur during engine operation, preventing leaks and ensuring that the engine’s internal components remain protected from contaminants.

QST30 CM2350 T101

Similarly, in the QST30 CM2350 T101 engine, the Bellows part 3645409 is integral to the engine’s sealing mechanism. Its design allows it to flex and bend as needed, providing a reliable seal that is essential for maintaining the engine’s performance and longevity. This part is particularly important in environments where the engine is exposed to varying temperatures and pressures, as it helps to mitigate the effects of thermal expansion and contraction.

Grouping of Engines

Both the QSK50 CM2350 K108 and QST30 CM2350 T101 engines share a common requirement for the Bellows part 3645409. This part’s ability to adapt to the dynamic conditions within the engine makes it a crucial component in ensuring the reliability and efficiency of these engines. Its design and material properties are tailored to meet the specific needs of these engine models, providing a seamless fit and optimal performance.

Role of Part 3645409 Bellows in Engine Systems

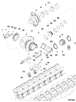

Turbocharger Integration

Part 3645409 Bellows is instrumental in the turbocharger arrangement of engine systems. It is positioned between the exhaust manifold and the turbocharger turbine housing. This placement allows it to absorb and accommodate the thermal expansion and contraction that occur due to the high temperatures and pressures within the exhaust system. By doing so, the Bellows ensures a secure and flexible connection, which is essential for maintaining the integrity of the turbocharger system. This flexibility helps in reducing stress on the joints and connections, thereby enhancing the durability and efficiency of the turbocharger.

Exhaust Manifold Arrangement

In the exhaust manifold arrangement, Part 3645409 Bellows plays a significant role by providing a flexible link between the engine block and the exhaust manifold. This flexibility is vital as it allows for the natural movement and expansion of the engine components during operation. The Bellows helps in mitigating the effects of thermal cycling, which can lead to cracking or failure of rigid connections. By ensuring a robust and reliable connection, the Bellows contributes to the overall performance and longevity of the exhaust system.

Overall Engine System Benefits

The incorporation of Part 3645409 Bellows in these engine components results in several benefits. It enhances the reliability of the turbocharger by preventing stress-induced failures. Additionally, it improves the efficiency of the exhaust system by maintaining a secure and flexible connection. This, in turn, contributes to the overall performance and durability of the engine system. The Bellows’ ability to adapt to the dynamic conditions within the engine ensures that the components remain connected and functional, even under extreme operating conditions.

Conclusion

The Cummins 3645409 Bellows is a vital component in commercial truck operations, offering flexibility, durability, and resistance to environmental factors. Its role in connecting various systems within the truck ensures smooth and efficient operation, contributing to the vehicle’s overall reliability and efficiency. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this Cummins part, ensuring long-term performance and reliability in commercial truck engines.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.