This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

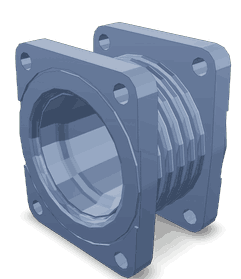

Bellows are flexible elements used in various mechanical systems to accommodate movement, vibration, and thermal expansion while maintaining a seal between connected components. They operate by flexing and expanding to allow for relative motion between parts, ensuring that fluids or gases can pass through without leakage. Bellows are commonly employed in industries such as automotive, aerospace, and manufacturing, where they play a vital role in maintaining system integrity and efficiency 1.

Purpose of the 3649076 Bellows in Truck Operations

The 3649076 Bellows serves a specific function within the operation of commercial trucks. It is designed to connect various components in the truck’s system, allowing for movement and flexibility while ensuring a secure seal. This bellows plays a role in accommodating the dynamic movements and vibrations that occur during truck operation, which helps maintain the integrity of the system and ensures efficient performance. By providing a flexible connection, it contributes to the overall reliability and durability of the vehicle 3.

Key Features of the 3649076 Bellows

The 3649076 Bellows is characterized by several distinctive features that enhance its performance and durability. Constructed from high-quality materials, it is designed to withstand the rigors of truck operation. The bellows utilizes advanced construction techniques to ensure flexibility and strength. Its unique design includes multiple convolutions that allow for significant movement and expansion, while maintaining a tight seal. These features contribute to its longevity and effectiveness in demanding applications 2.

Benefits of Using the 3649076 Bellows

The 3649076 Bellows offers several advantages that contribute to the longevity and reliability of commercial trucks. Its improved flexibility allows it to accommodate a wide range of movements and vibrations, reducing the risk of wear and tear on connected components. The bellows’ resistance to environmental factors ensures durable performance over time. Additionally, its enhanced sealing capabilities help prevent leaks, maintaining system efficiency and safety. These benefits make the 3649076 Bellows a valuable component in truck operations 1.

Troubleshooting and Maintenance Suggestions

To ensure optimal performance of the 3649076 Bellows, it is important to be aware of common issues such as leaks or reduced flexibility. Regular inspection for signs of wear, damage, or deformation is recommended. Cleaning the bellows and its surrounding areas can help prevent buildup that may affect its function. If any issues are detected, prompt repair or replacement is advised to maintain system integrity. Following manufacturer guidelines for maintenance will help ensure the bellows continues to perform effectively 3.

Installation and Compatibility

Proper installation of the 3649076 Bellows is crucial for its effective function. It is important to follow specific requirements and precautions during installation to ensure a secure and proper fit. Compatibility with various truck models and systems should be considered to ensure the bellows integrates seamlessly into the existing setup. Adhering to installation guidelines will help achieve the best performance and longevity from the component 2.

Cummins: A Brief Overview

Cummins Inc. is a renowned leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. With a rich history of innovation and quality, Cummins has established itself as a trusted name in the automotive industry. The company’s commitment to advancing engine technology and providing reliable solutions has made it a preferred choice for commercial vehicle applications. Cummins continues to push the boundaries of engine performance and efficiency, contributing to the success of its customers worldwide 3.

Bellows Part 3649076 in Cummins Engines

The Bellows part 3649076, manufactured by Cummins, is an essential component in several engine models. This part is designed to provide flexibility and durability, ensuring smooth operation and longevity of the engine.

QSV91-G4 CM558/CM700 V102 and QSV91G Engines

In the QSV91-G4 CM558/CM700 V102 and QSV91G engines, the Bellows part 3649076 plays a crucial role in maintaining the integrity of the engine’s sealing system. This part is typically used to connect different sections of the engine, allowing for movement and expansion without compromising the seal. Its flexibility helps in accommodating thermal expansion and contraction, thereby preventing leaks and maintaining optimal engine performance.

The Bellows part 3649076 is engineered to withstand the high temperatures and pressures typical in these engines, ensuring that it can endure the demanding conditions of engine operation. Its robust design and material composition make it a reliable choice for these applications, contributing to the overall efficiency and reliability of the engine.

By integrating this part into the engine design, Cummins ensures that the engines can operate smoothly and efficiently, with minimal maintenance requirements. The Bellows part 3649076 is a testament to Cummins’ commitment to quality and durability in their engine components 3.

Role of Part 3649076 Bellows in Engine Systems

The 3649076 Bellows is an essential component in various engine systems, particularly in the exhaust system. Its primary function is to accommodate the thermal expansion and contraction that occur within the exhaust system due to the high temperatures generated during engine operation.

Exhaust Manifold

In the exhaust manifold, the 3649076 Bellows is positioned between the engine block and the manifold itself. This placement allows it to absorb the differential expansion rates between the engine block and the manifold. As the engine heats up, both components expand, but at different rates. The bellows flexes to accommodate this movement, preventing stress and potential cracking in the manifold or the engine block.

Exhaust Outlet Kit

When integrated into an exhaust outlet kit, the 3649076 Bellows serves a similar purpose. It is often found between the exhaust manifold and the downpipe. This connection point experiences significant thermal cycling, and the bellows ensures that the joint remains intact and leak-free despite the constant expansion and contraction.

Manifold Connections

In manifold-to-manifold connections, especially in V-configuration engines, the 3649076 Bellows is used to connect the two manifolds. This application is particularly important in high-performance engines where thermal expansion is more pronounced. The bellows allows for the necessary flexibility to maintain a secure and sealed connection, ensuring efficient exhaust flow and reducing the risk of exhaust leaks.

Exhaust System Flexibility

Throughout the exhaust system, the 3649076 Bellows is employed in various joints to provide flexibility. Whether connecting the downpipe to the catalytic converter or linking different sections of the exhaust pipe, the bellows ensures that the system can withstand the thermal stresses without compromising integrity. This flexibility is vital for maintaining the overall performance and durability of the exhaust system.

Conclusion

In summary, the 3649076 Bellows plays a significant role in enhancing the durability and efficiency of engine systems by providing necessary flexibility in high-stress, high-temperature environments. Its integration into Cummins engines exemplifies the importance of this component in maintaining system integrity and performance 3.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ ↩ -

Pawel Drozdziel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ ↩ -

Konrad Reif Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.