This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3649569 Centrifuge is a specialized component designed for use in commercial truck operations. Its primary function is to enhance the efficiency and reliability of the truck’s fuel system by separating water and other contaminants from the diesel fuel. This separation process ensures that the fuel delivered to the engine is clean, which contributes to optimal engine performance and longevity 3.

Basic Concepts of Centrifuges

A centrifuge is a device that uses centrifugal force to separate various components of a fluid. This is achieved by spinning the fluid at high speed within a container, which may be a centrifuge tube or bottle. The denser components of the fluid are pulled to the outer edge of the container, while the less dense components remain closer to the center. This principle is fundamental to the operation of the Cummins 3649569 Centrifuge, which effectively separates water and contaminants from diesel fuel 2.

Purpose of the Cummins 3649569 Centrifuge

The Cummins 3649569 Centrifuge plays a significant role in the operation of commercial trucks by ensuring that the fuel supplied to the engine is free from water and contaminants. This separation process helps maintain the integrity of the fuel system, reduces the risk of engine damage, and enhances overall truck performance. The centrifuge is particularly beneficial in environments where fuel quality may be compromised, such as in regions with high humidity or where fuel storage practices are suboptimal 3.

Key Features

The Cummins 3649569 Centrifuge is designed with several key features that enhance its functionality and durability. These include a robust construction using high-quality materials to withstand the rigors of commercial truck operations. The centrifuge incorporates advanced technological elements such as precise engineering to ensure efficient separation of contaminants from diesel fuel. Additionally, it is designed for easy integration into existing truck fuel systems, minimizing installation complexity 1.

Benefits of Using the Cummins 3649569 Centrifuge

Utilizing the Cummins 3649569 Centrifuge in commercial truck operations offers several advantages. These include improved fuel system efficiency, enhanced engine performance, and increased reliability. By ensuring that the fuel delivered to the engine is clean, the centrifuge helps prevent issues such as engine misfires, reduced power output, and increased wear on engine components. Furthermore, the centrifuge contributes to longer engine life and reduced maintenance costs by minimizing the impact of contaminants on the fuel system 3.

Installation and Integration

Proper installation and integration of the Cummins 3649569 Centrifuge into a truck’s fuel system are crucial for optimal performance. The installation process involves several steps, including ensuring that the fuel system is clean and free from contaminants before installation, mounting the centrifuge in a location that allows for easy access for maintenance, and connecting it to the fuel lines according to the manufacturer’s specifications. It is also important to verify that all connections are secure and that the centrifuge is properly aligned within the fuel system 1.

Operational Procedures

Operating the Cummins 3649569 Centrifuge involves following specific procedures to ensure efficient and safe performance. Startup procedures include verifying that the centrifuge is properly installed and that all connections are secure. During runtime, it is important to monitor the centrifuge’s performance and ensure that it is effectively separating contaminants from the fuel. Shutdown procedures involve allowing the centrifuge to complete its separation cycle before shutting down the truck’s engine to ensure that any remaining contaminants are properly separated from the fuel 3.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3649569 Centrifuge is essential for ensuring its longevity and optimal performance. Maintenance practices include regular inspection of the centrifuge for signs of wear or damage, cleaning the centrifuge according to the manufacturer’s recommendations, and replacing any worn or damaged components as needed. Troubleshooting tips for common issues such as reduced separation efficiency or unusual noises during operation may involve checking for proper installation, ensuring that the fuel system is clean, and verifying that all connections are secure 1.

Common Issues and Solutions

Frequent problems associated with the Cummins 3649569 Centrifuge may include reduced separation efficiency, unusual noises during operation, or leaks in the fuel system. Solutions or workarounds for these issues may involve checking for proper installation, ensuring that the fuel system is clean and free from contaminants, and verifying that all connections are secure. In some cases, replacing worn or damaged components may be necessary to restore optimal performance 3.

Safety Considerations

When working with the Cummins 3649569 Centrifuge, it is important to observe several safety guidelines and precautions to prevent accidents and ensure safe operation. These include wearing appropriate personal protective equipment (PPE) when handling the centrifuge, ensuring that the fuel system is depressurized before performing any maintenance or repairs, and following all manufacturer’s recommendations for installation, operation, and maintenance. Additionally, it is important to be aware of the potential hazards associated with working with diesel fuel, such as flammability and toxicity, and to take appropriate precautions to mitigate these risks 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and fuel systems. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial trucks 3.

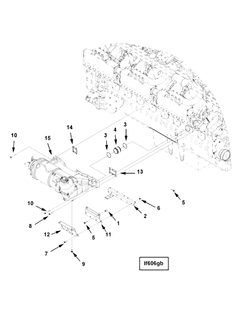

Cummins Engine Part 3649569: Centrifuge Integration

The Cummins part 3649569, identified as a Centrifuge, is integral to the maintenance and operational efficiency of several Cummins engine models. This part is designed to facilitate the separation of fluids and contaminants, ensuring the longevity and optimal performance of the engines.

QSK78 Series

In the QSK78 series, the Centrifuge part 3649569 plays a crucial role in the engine’s lubrication system. It helps in the purification of engine oil by removing particulate matter and other impurities. This ensures that the engine oil remains clean and effective in lubricating the engine’s moving parts, thereby reducing wear and tear 3.

CM500 Series

Similarly, in the CM500 series, the Centrifuge part 3649569 is employed to maintain the cleanliness of the engine’s hydraulic system. By separating contaminants from the hydraulic fluid, it helps in preventing damage to the hydraulic components and ensures smooth operation of the engine’s hydraulic systems 3.

Integration and Functionality

The integration of the Centrifuge part 3649569 in these engines is designed to be straightforward, allowing for easy installation and removal during maintenance procedures. Its placement within the engine’s system is strategically chosen to maximize its efficiency in filtering and separating fluids. This ensures that the engine operates at peak performance levels, with minimal risk of contamination-related failures 3.

Understanding the Role of Part 3649569 Centrifuge in Engine Systems

In the intricate dance of engine components, part 3649569 Centrifuge assumes a significant role, particularly in relation to the filter, lubricating oil, and lubricating oil filter head. This component is instrumental in maintaining the efficiency and longevity of these essential engine elements.

Interaction with the Filter

The Centrifuge works in tandem with the filter to ensure that the engine oil remains clean and free from contaminants. As the oil circulates through the engine, it picks up debris and particles that can cause wear and tear. The Centrifuge aids in this process by spinning the oil at high speeds, allowing heavier particles to separate from the oil and be captured by the filter. This ensures that the oil remains in optimal condition, promoting smoother engine operation 2.

Contribution to Lubricating Oil Efficiency

Lubricating oil is the lifeblood of any engine, reducing friction between moving parts and dissipating heat. Part 3649569 Centrifuge enhances the efficiency of the lubricating oil by ensuring that it is free from impurities. By continuously purifying the oil, the Centrifuge helps maintain the oil’s viscosity and lubricating properties, which are vital for the engine’s performance and durability 2.

Synergy with the Lubricating Oil Filter Head

The lubricating oil filter head is designed to capture contaminants that have been separated from the oil. Part 3649569 Centrifuge complements this function by pre-separating larger particles before they reach the filter head. This not only extends the lifespan of the filter head but also ensures that the oil filtration process is more effective. The Centrifuge’s role in this synergy is to provide a preliminary layer of purification, making the subsequent filtration process more efficient and reliable 2.

Conclusion

In summary, part 3649569 Centrifuge is a valuable component in the engine system, working seamlessly with the filter, lubricating oil, and lubricating oil filter head to ensure that the engine operates at peak performance. Its ability to purify the oil and enhance the efficiency of other components makes it an indispensable part of the engine’s maintenance and operation 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.