This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

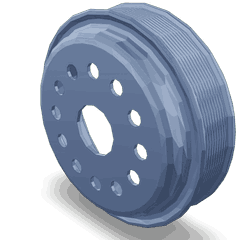

The Crankshaft Pulley 3680190, manufactured by Cummins, is a component designed for use in commercial truck engines. Cummins, a well-established name in the engine manufacturing industry, produces this pulley to meet the demanding requirements of heavy-duty applications. This part is integral to the efficient operation of truck engines, contributing to their performance and reliability.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a component attached to the front of an engine’s crankshaft. Its primary function is to drive various engine accessories through a belt or chain system. In the context of a truck’s powertrain, the crankshaft pulley transmits rotational force from the crankshaft to components such as the alternator, water pump, and air conditioning compressor, enabling these systems to operate 1.

Purpose of the 3680190 Crankshaft Pulley

The 3680190 Crankshaft Pulley plays a role in the operation of a truck by facilitating the transfer of power from the crankshaft to essential engine accessories. It interacts with the engine’s timing belt or chain, ensuring synchronized operation of components like the alternator and water pump. This pulley contributes to overall engine performance by maintaining the efficiency and reliability of these accessory systems 2.

Key Features

The 3680190 Crankshaft Pulley is characterized by specific design and construction features that enhance its functionality and durability. These include a robust material composition, precise balancing to minimize vibrations, and secure attachment mechanisms that ensure stable operation under the high stresses of heavy-duty use 3.

Benefits

The advantages provided by the 3680190 Crankshaft Pulley include improved engine efficiency through reliable power transmission to accessories, reduced wear on connected components due to its balanced design, and enhanced reliability in heavy-duty applications, ensuring consistent performance under demanding conditions 4.

Installation and Compatibility

Proper installation of the 3680190 Crankshaft Pulley involves following manufacturer guidelines to ensure correct alignment and secure attachment. This may require specific tools and precautions to avoid damage to the pulley or engine. Compatibility with various Cummins engine models is ensured through careful design and engineering, allowing for seamless integration into the engine system.

Maintenance and Troubleshooting

Routine maintenance practices for the 3680190 Crankshaft Pulley include regular inspection for signs of wear or damage, ensuring the belt or chain remains in good condition, and addressing any unusual noises or vibrations promptly. Common issues may involve belt slippage or pulley misalignment, which can often be resolved through adjustment or replacement of worn components.

Performance Enhancements

Upgrades or modifications to the 3680190 Crankshaft Pulley can affect engine performance by potentially increasing power output and efficiency. These enhancements may include the use of higher-quality materials or designs that reduce friction and improve power transmission, contributing to overall engine performance.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of engine products and commitment to quality and innovation. With a history of producing reliable and efficient engine components, Cummins has established a reputation for excellence in the heavy-duty truck market, continually advancing engine technology to meet the evolving needs of its customers.

Conclusion

The Crankshaft Pulley 3680190 by Cummins is a vital component in the operation of commercial truck engines, ensuring efficient power transmission to essential accessories and contributing to the overall performance and reliability of the engine. Its robust design, precise balancing, and compatibility with various Cummins engine models make it a reliable choice for heavy-duty applications.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩ -

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.