This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Check Ball Part #3680700 is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s systems, contributing to the overall efficiency and reliability of the truck’s operation. Understanding its purpose and significance can help fleet operators and technicians maintain optimal performance of their vehicles.

Basic Concepts of Check Balls

A check ball is a small, spherical valve used in hydraulic or fuel systems to regulate the flow of fluid. It allows fluid to pass in one direction while preventing backflow in the opposite direction. This function is vital for maintaining system integrity, ensuring that fluid moves through the system as intended without unwanted reversals that could lead to inefficiencies or damage 1.

Purpose of Cummins Check Ball Part #3680700

This Cummins part plays a role in the operation of a truck by functioning within the fuel injection system or hydraulic circuits. It ensures that fuel or hydraulic fluid flows in the correct direction, which is important for the proper operation of these systems. By preventing backflow, it helps maintain consistent pressure and flow, which is necessary for the efficient and reliable performance of the truck 2.

Key Features

The Cummins Check Ball Part #3680700 is characterized by its precise design and material composition. It is typically made from durable materials that can withstand the pressures and temperatures within a truck’s systems. Its design ensures a snug fit within the system, minimizing the risk of leaks and ensuring effective operation. These features contribute to its performance and durability, making it a reliable component for commercial truck applications.

Benefits

Using the Cummins Check Ball Part #3680700 can lead to improved system efficiency and reliability. By ensuring proper fluid flow, it helps maintain the performance of the fuel injection or hydraulic systems. This can result in better overall truck performance and potentially lower maintenance costs for fleet operators, as a well-maintained system is less likely to experience failures or require frequent repairs.

Installation and Usage

Proper installation of this part is important for its effective operation. It should be installed according to the manufacturer’s guidelines, which may include specific procedures or precautions to ensure it fits correctly and functions as intended. Regular checks and maintenance can help ensure its continued effectiveness within the system.

Troubleshooting and Maintenance

Common issues with this Cummins part may include blockages or wear that affects its ability to regulate fluid flow. Regular maintenance, such as cleaning and inspection, can help identify and address these issues before they lead to system failures. Signs of wear or failure, such as inconsistent system performance or leaks, may indicate the need for replacement.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and industrial markets. The company is known for its commitment to reliability and performance, making its parts, including the Cummins Check Ball Part #3680700, a trusted choice for fleet operators and technicians.

Compatibility

This check ball is compatible with several Cummins engine models, including the ISX, ISX15, QSX, and X15 series. It is integral to maintaining the fluid dynamics within these engines, ensuring optimal performance and longevity.

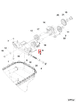

Role in Engine Systems

The Check Ball plays a significant role in various engine systems, ensuring the proper functioning and efficiency of these systems. Its primary role is to regulate the flow of lubricating oil within the engine, thereby maintaining optimal lubrication and performance.

Lubricating Oil Pump

In the lubricating oil pump, the Check Ball ensures that oil flows in the correct direction, preventing backflow which could lead to inefficient lubrication. This is particularly important in high-pressure systems where consistent oil delivery is necessary to protect moving parts from wear and tear.

Lubricating Pump Kit

When integrated into a lubricating pump kit, the Check Ball contributes to the overall efficiency of the lubrication system. It helps in maintaining the desired pressure levels, ensuring that all engine components receive adequate lubrication.

Overhaul Kit

In an overhaul kit, the Check Ball is often included to replace worn-out or damaged components during engine maintenance. Its role here is to restore the proper function of the lubrication system, ensuring that the engine operates smoothly post-overhaul.

General Pump Applications

Across various pump applications within the engine system, the Check Ball ensures that oil is directed correctly and maintains the necessary pressure. This is essential for the efficient operation of the pump, as it prevents issues such as cavitation and ensures that the pump can deliver oil consistently to all required areas of the engine.

Lubricating Oil System

In the broader lubricating oil system, the Check Ball helps in regulating the flow of oil to critical engine components. By preventing backflow and ensuring consistent pressure, it plays a key role in maintaining the integrity of the lubrication system.

Conclusion

The Cummins Check Ball Part #3680700 is a critical component in maintaining the efficiency and reliability of commercial truck engines. Its role in regulating fluid flow within various systems ensures optimal performance and longevity of the engine. Proper installation, regular maintenance, and understanding its compatibility with different Cummins engine models are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.