This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

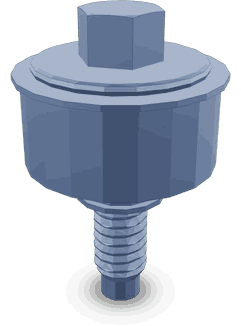

The Cummins 3681037 Noise Isolator is designed to reduce noise levels produced by heavy-duty trucks. It mitigates noise generated by the engine and exhaust system, enhancing driver comfort and ensuring compliance with noise emission regulations.

Basic Concepts of Noise Isolators

A noise isolator reduces the transmission of sound waves from a source to its surroundings. In commercial trucks, these devices minimize engine and exhaust noise, creating a quieter environment for drivers and nearby communities. The effectiveness of a noise isolator depends on its design, material, and placement within the vehicle’s system 1.

Purpose of the Cummins 3681037 Noise Isolator

The Cummins 3681037 Noise Isolator is positioned within the exhaust system of heavy-duty trucks. Its primary function is to absorb and reduce engine exhaust noise. This isolator is designed to fit seamlessly into the exhaust path, dissipating sound waves before they exit the vehicle, thereby reducing the overall noise level produced by the truck 2.

Key Features

The Cummins 3681037 Noise Isolator is constructed from materials effective at absorbing sound, ensuring durability and longevity. Its design maximizes noise reduction while maintaining the efficiency of the exhaust system. It is engineered to withstand the harsh conditions typical of heavy-duty truck operations, ensuring reliable performance over time.

Benefits of Using the Cummins 3681037 Noise Isolator

Incorporating the Cummins 3681037 Noise Isolator into a truck’s exhaust system offers several advantages. It effectively reduces engine and exhaust noise, contributing to a more comfortable driving environment. This reduction in noise can also enhance the overall experience for passengers and reduce disturbance to those in the vicinity of the vehicle. Furthermore, by helping trucks meet noise emission standards, it supports compliance with regulatory requirements, which is important for fleet operations 3.

Installation Process

Installing the Cummins 3681037 Noise Isolator involves several steps to ensure it is properly fitted and functions as intended. The process begins with locating the correct position within the exhaust system. Tools required may include wrenches and possibly a sealant to ensure a tight fit. It is important to follow the manufacturer’s instructions closely to ensure the isolator is securely installed and operates effectively. Proper installation is key to achieving the desired noise reduction and maintaining the efficiency of the exhaust system.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3681037 Noise Isolator is relatively straightforward. Regular inspections should be conducted to ensure it remains securely in place and is free from damage. Common issues may include loosening of the isolator or damage to its structure, which can affect its performance. Troubleshooting typically involves checking for these issues and making necessary adjustments or replacements to maintain optimal noise reduction.

Regulatory Compliance

The Cummins 3681037 Noise Isolator plays a role in helping trucks meet noise emission standards and regulations. Compliance with these standards is important for fleet operations, as it ensures vehicles operate within legal limits and contribute to a reduction in environmental noise pollution. Using noise isolators like the Cummins 3681037 is one way fleets can demonstrate their commitment to operating responsibly and in accordance with regulatory requirements.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to innovation and quality in automotive components. With a history of developing reliable and efficient parts, Cummins has built a reputation for excellence. The company’s focus on advancing technology and meeting the needs of its customers underscores its position as a leader in the industry.

Noise Isolator 3681037 in Cummins Engines

The Noise Isolator part 3681037, manufactured by Cummins, is a component designed to mitigate unwanted noise in various Cummins engine models. This part is engineered to fit seamlessly within the engine’s architecture, ensuring optimal performance and reduced noise levels.

ISX CM570

In the ISX CM570 engine, the Noise Isolator 3681037 is strategically positioned to absorb and dampen vibrations and noise generated during engine operation. This placement is important for maintaining a quieter cabin environment, which is particularly beneficial in applications where noise reduction is a priority, such as in commercial vehicles and heavy machinery.

CM570

Similarly, in the CM570 engine, the Noise Isolator 3681037 plays a pivotal role in noise management. Its design allows it to effectively isolate noise from the engine compartment, contributing to a more comfortable and less disruptive operational environment. This is especially important in settings where prolonged exposure to engine noise could impact worker productivity and well-being.

Role of Part 3681037 Noise Isolator in Engine Systems

The part 3681037 Noise Isolator is instrumental in mitigating unwanted noise generated by various engine components, ensuring a quieter and more efficient operation. When integrated with the Valve Cover, the Noise Isolator effectively dampens the vibrations and sounds produced by the moving parts within the Valve Cover, such as the camshaft and valve train. This reduction in noise not only contributes to a quieter engine environment but also helps in minimizing the wear and tear on surrounding components by stabilizing the vibrations.

Additionally, the Noise Isolator plays a significant role in enhancing the overall performance and longevity of the engine. By reducing the transmission of vibrations, it aids in maintaining the integrity of the Valve Cover seals and gaskets, preventing potential leaks and ensuring optimal engine operation. Furthermore, the Noise Isolator supports the consistent functioning of the engine by providing a stable environment for the Valve Cover to operate, which is essential for precise valve timing and efficient combustion processes.

Conclusion

In summary, the incorporation of the part 3681037 Noise Isolator with the Valve Cover is a strategic approach to achieving a balanced, efficient, and durable engine system. Its role in noise reduction and vibration dampening contributes significantly to the overall performance and longevity of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.