This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

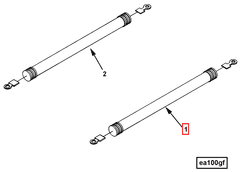

The Cummins 3681337 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. Its role is significant in ensuring the reliable operation of electrical systems within commercial trucks, contributing to overall vehicle performance and safety 1.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It consists of multiple wires bundled together, often protected by a sheath, to prevent damage and reduce the risk of short circuits. Within a vehicle’s electrical system, the wiring harness plays a role in distributing power from the battery to various electrical components, such as lights, sensors, and control units, ensuring they operate correctly 2.

Purpose of the 3681337 Wiring Harness

The Cummins 3681337 Wiring Harness is specifically designed to integrate with the electrical systems of commercial trucks. It facilitates the connection between the truck’s power source and its electrical components, enabling the operation of critical systems such as lighting, engine controls, and diagnostic systems. By providing a structured and protected pathway for electrical signals and power, it plays a role in ensuring the efficient and reliable operation of the truck’s electrical systems 3.

Key Features

The 3681337 Wiring Harness is characterized by its robust design and the quality of materials used in its construction. It is built to withstand the harsh conditions often encountered in commercial truck operations, including exposure to vibrations, temperature extremes, and moisture. The harness is designed with precision to fit specific truck models, ensuring compatibility and ease of installation. Unique characteristics may include specialized connectors for secure attachment and protective coatings to enhance durability 4.

Benefits of Using the 3681337 Wiring Harness

Utilizing the 3681337 Wiring Harness offers several advantages. Its design contributes to the efficiency of the truck’s electrical system by providing a direct and protected pathway for electrical signals and power. The harness is engineered for reliability, reducing the likelihood of electrical failures and enhancing the overall performance of the truck. Additionally, its design facilitates ease of installation, allowing for straightforward integration into the vehicle’s electrical system 5.

Installation Process

Installing the 3681337 Wiring Harness involves several steps to ensure proper integration with the truck’s electrical system. Begin by identifying the correct location for the harness within the truck, following the manufacturer’s guidelines. Securely connect the harness to the power source and route it to the various electrical components it serves. Ensure all connections are tight and protected from potential damage. Testing the electrical system post-installation is recommended to confirm proper operation 6.

Common Issues and Troubleshooting

Wiring harnesses, including the 3681337, may encounter issues such as loose connections, damaged wires, or faulty connectors. These problems can lead to electrical malfunctions or failures. Troubleshooting involves inspecting the harness for visible damage, ensuring all connections are secure, and testing the electrical system for proper operation. Solutions may include repairing or replacing damaged sections of the harness or connectors to restore functionality 7.

Maintenance Tips

Regular maintenance of the 3681337 Wiring Harness is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, ensuring all connections remain secure, and protecting the harness from physical damage or exposure to harsh conditions. Keeping the harness clean and free from debris can also contribute to its reliable operation 8.

Safety Considerations

When working with the 3681337 Wiring Harness, it is important to observe safety protocols to prevent electrical shocks or injuries. This includes disconnecting the battery before beginning any work on the electrical system, using insulated tools, and ensuring the work area is well-lit and free from hazards. Adhering to these safety measures helps protect both the technician and the vehicle’s electrical system 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the commercial truck industry, providing reliable and efficient power solutions. Its commitment to innovation and quality has made it a preferred choice for commercial vehicle operators worldwide.

Cummins Wiring Harness 3681337 Compatibility

The Cummins Wiring Harness part number 3681337 is designed to integrate seamlessly with various Cummins engine models, ensuring reliable electrical connectivity and system functionality. This wiring harness is a component for maintaining the operational integrity of the engine’s electrical system.

ISX CM570

For the ISX CM570 engine, the Wiring Harness 3681337 is engineered to fit precisely, ensuring that all electrical connections are made correctly. This harness is for the proper functioning of the engine’s control systems, sensors, and other electrical components. Its design allows for easy installation and maintenance, reducing downtime and ensuring the engine operates at peak efficiency.

Grouping of Engines

The Wiring Harness 3681337 is not limited to just the ISX CM570 engine; it is also compatible with other Cummins engine models within the same series. This compatibility ensures that technicians and mechanics can use a single part number for multiple engine types, simplifying inventory management and reducing the need for multiple part numbers.

The harness is designed to meet the specific electrical requirements of each engine model, ensuring that it fits perfectly and functions as intended. This design philosophy allows for a standardized approach to engine maintenance and repair, enhancing overall reliability and performance.

Role of Part 3681337 Wiring Harness in Engine Systems

The Part 3681337 Wiring Harness is an integral component in the electrical architecture of engine systems, facilitating the seamless integration and operation of various accessories and electrical components.

Integration with Accessories

This wiring harness is designed to connect a wide array of accessories to the engine system. These accessories may include, but are not limited to, fuel pumps, ignition systems, and emission control devices. By providing a structured pathway for electrical signals and power, the harness ensures that these accessories receive the necessary voltage and current to function correctly. This integration is essential for the accessories to operate in sync with the engine’s performance, enhancing overall efficiency and reliability.

Electrical Component Connectivity

In the realm of electrical components, the Part 3681337 Wiring Harness plays a role in connecting sensors, actuators, and control modules. Sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensor, and Manifold Absolute Pressure (MAP) sensor rely on the harness to transmit data to the Engine Control Unit (ECU). Similarly, actuators like the throttle position actuator and various solenoids depend on the harness for receiving commands from the ECU. This bidirectional flow of information and power is vital for the precise control and monitoring of engine operations.

Enhanced System Performance

The structured and organized nature of the Part 3681337 Wiring Harness reduces the risk of electrical interference and signal loss, which can otherwise lead to malfunctions or reduced performance of connected components. Its design also allows for easier troubleshooting and maintenance, as the harness can be systematically inspected for any signs of wear, corrosion, or damage.

Safety and Reliability

By ensuring a secure and consistent electrical connection, the Part 3681337 Wiring Harness contributes to the safety and reliability of the engine system. It helps in maintaining the integrity of the electrical signals, which is paramount for the accurate operation of safety-critical systems such as the airbag deployment system and anti-lock braking system (ABS).

Conclusion

In summary, the Part 3681337 Wiring Harness is a fundamental component that enhances the functionality, performance, and safety of engine systems by providing a reliable and organized electrical connection to various accessories and electrical components.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Cummins Inc. (n.d.). Service Manual (5579952). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5579952). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5579952). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5579952). Cummins Inc.

↩ -

Cummins Inc. (n.d.). Service Manual (5579952). Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.