This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

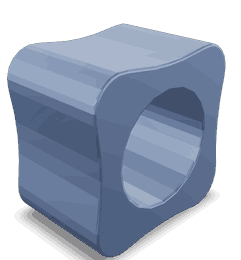

Introduction to Vibration Isolators

Vibration isolators are specialized components designed to minimize the transmission of vibrations from one part of a system to another. In the context of commercial trucks, these devices play a crucial role in ensuring the smooth operation of the vehicle by reducing the impact of engine vibrations on the truck’s chassis and other components. Cummins, a leading name in the automotive industry, has developed the 3681906 vibration isolator to meet the demanding requirements of heavy-duty applications. This component is integral to maintaining the efficiency and longevity of Cummins engines, ensuring that trucks operate smoothly and reliably under various conditions 1.

How a Vibration Isolator Works

The mechanics of vibration isolation involve the use of materials and designs that absorb and dampen vibrations. A typical vibration isolator consists of an elastomeric material, often rubber, encased in metal mounts. The elastomeric core provides the necessary elasticity to absorb vibrations, while the metal mounts offer structural support and durability. Damping, the process of reducing the amplitude of vibrations over time, is achieved through the inherent properties of the elastomeric material, which converts vibrational energy into heat 2.

Purpose of the 3681906 Vibration Isolator

The 3681906 vibration isolator is specifically designed for use in Cummins engines, where it plays a vital role in reducing engine vibration. By effectively isolating the engine from the truck’s chassis, this component helps to improve operational efficiency, reduce wear and tear on engine mounts and other components, and enhance the overall performance and longevity of the truck. The isolator contributes to a smoother ride, increased driver comfort, and reduced maintenance costs, making it an essential part of the engine system 3.

Troubleshooting and Maintenance

Common issues associated with vibration isolators include wear and tear, cracking, and loss of elasticity, which can lead to increased engine vibration and reduced effectiveness. Diagnostic techniques for identifying problems with the 3681906 vibration isolator include visual inspection for signs of damage, measuring vibration levels with specialized equipment, and assessing the overall condition of the isolator. Maintenance practices to ensure optimal performance include regular inspection, cleaning, and replacement of the isolator as needed. It is recommended to follow the manufacturer’s guidelines for servicing intervals to ensure the isolator remains in top condition.

Expert Insights on Cummins Vibration Isolators

Industry experts highlight the effectiveness of Cummins vibration isolators in reducing engine vibrations and improving truck performance. Case studies and real-world applications demonstrate the significant impact these components have on the longevity and reliability of Cummins engines. Testimonials from engineers and mechanics underscore the importance of proper installation and maintenance to ensure the isolator functions as intended.

Role of Part 3681906 Vibration Isolator in Engine Systems

The 3681906 vibration isolator is instrumental in maintaining the operational integrity of various engine components by mitigating vibrations that can adversely affect performance and longevity.

In the context of the Cooler system, the vibration isolator ensures that the Engine Oil Cooler operates efficiently. By reducing vibrations, it helps maintain the structural integrity of the Oil Cooler Tube, preventing potential leaks or damage that could compromise the cooling efficiency of the engine oil.

When integrated with the Engine Oil system, the vibration isolator supports the Lubricating Oil Filter Head and the Lubricating Oil Filter Head Kit. This integration is vital for ensuring that the filter head remains securely in place and functions optimally, thereby enhancing the filtration process and protecting the engine from contaminants.

Overall, the vibration isolator plays a significant role in preserving the stability and efficiency of these interconnected components, contributing to the smooth and reliable operation of the engine system.

Conclusion

The 3681906 vibration isolator by Cummins is a critical component in the engine system of commercial trucks, playing a vital role in reducing engine vibrations and improving operational efficiency. By understanding the function and maintenance of this component, mechanics and engineers can ensure the smooth and reliable operation of Cummins engines, contributing to the overall performance and longevity of the truck.

Additional Resources

For further reading and technical documents, visit the Cummins website. For support and service, contact Cummins directly using the information provided on their official site.

-

Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, Haoran Hu, Simon J Baseley and Xubin Song, SAE International, 2021.

↩ -

Automotive Transmissions Fundamentals Selection Design and Application, Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Springer Vieweg, 2011.

↩ -

Automotive Braking Systems, Nicholas Goodnight and Kirk Van Gelder, Jones & Bartlett Learning, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.