This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

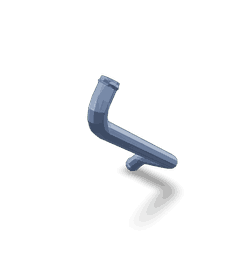

The Compressor Air Inlet Tube, identified by part number 3684455, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This tube is integral to the air system of heavy-duty trucks, facilitating the efficient operation of the compressor. Cummins is renowned for its commitment to producing high-quality components that enhance the performance and reliability of vehicles 1.

Basic Concepts and Functionality

The Compressor Air Inlet Tube operates on the fundamental principle of directing air into the compressor with minimal resistance. Within the truck’s air system, it serves as a conduit that ensures a steady and efficient supply of air to the compressor. This role is vital for maintaining the compressor’s efficiency and, by extension, the overall performance of the truck’s air system 2.

Purpose and Role in Truck Operation

This Cummins part is designed to contribute to the efficient operation of heavy-duty trucks. By providing a direct and unobstructed path for air to reach the compressor, it helps maintain the compressor’s efficiency. This, in turn, supports the truck’s overall system performance and reliability, ensuring that the air system operates smoothly under various conditions.

Key Features

The Compressor Air Inlet Tube is characterized by several key features that enhance its functionality and durability. These include its material composition, which is designed to withstand the rigors of heavy-duty truck operations, and its design elements that ensure efficient air flow. Additionally, any unique characteristics that further enhance its performance are incorporated into its design.

Benefits

The advantages of this part include improved air flow, which contributes to the compressor’s efficiency. It also helps in reducing noise levels associated with air intake, enhancing the overall driving experience. Furthermore, its durable construction ensures long-term reliability, and it may contribute to fuel efficiency and emissions reduction by optimizing the air supply to the compressor 3.

Installation and Integration

Proper installation and integration of the Compressor Air Inlet Tube within the truck’s air system are crucial for its optimal performance. This process involves ensuring compatibility with other components and making any necessary adjustments to facilitate a seamless fit. Detailed guidelines and considerations for this process are provided to ensure a successful integration.

Troubleshooting and Maintenance

Common issues that may arise with the Compressor Air Inlet Tube include blockages or damage that can impede air flow. Diagnostic procedures for identifying these problems are outlined, along with recommended maintenance practices. These practices are designed to ensure the tube’s optimal performance and longevity, minimizing the risk of operational disruptions.

Cummins Overview

Cummins has a long-standing reputation in the industry for manufacturing high-quality automotive components. With a history of innovation and commitment to excellence, Cummins continues to be a trusted name among professionals in the automotive and heavy-duty truck sectors. Their products, including the Compressor Air Inlet Tube, are a testament to their dedication to quality and performance 4.

Compatibility

The 3684455 is engineered to fit seamlessly with various Cummins engine models, ensuring optimal performance and reliability.

ISX CM871 Engines

The ISX CM871 engine series, known for its robust performance and efficiency, is one of the many models compatible with the Compressor Air Inlet Tube. This part is specifically designed to interface with the intricate design of the ISX CM871, providing a precise fit that enhances the engine’s overall air intake system. The compatibility ensures that the air entering the compressor is clean and free from obstructions, which is vital for maintaining the engine’s power output and efficiency.

Other Cummins Engines

Beyond the ISX CM871, the Compressor Air Inlet Tube is also compatible with a range of other Cummins engine models. This versatility makes it a valuable component for technicians and fleet managers who operate multiple engine types. The design of the tube is standardized to fit various engine configurations, ensuring that it can be used across different models without compromising performance. This compatibility is particularly beneficial for businesses that maintain a diverse fleet of vehicles powered by Cummins engines, as it allows for a more streamlined maintenance process.

Role of Part 3684455 Compressor Air Inlet Tube in Engine Systems

The Compressor Air Inlet Tube (part number 3684455) is a component in the air intake system of various engine setups. It is specifically designed to facilitate the smooth and efficient transfer of air from the compressor to the engine’s intake manifold.

Integration with Compressor Air Inlet Plumbing

When integrated with the Compressor Air Inlet Plumbing, the Compressor Air Inlet Tube ensures that the pressurized air from the compressor is directed without turbulence or loss of pressure. This setup is vital for maintaining the efficiency of the engine, as it ensures that the air-fuel mixture entering the combustion chamber is optimal.

The tube’s design allows for minimal resistance, which is important for high-performance engines where every bit of efficiency counts. It connects seamlessly with the compressor outlet and the intake manifold, creating a sealed pathway that prevents air leaks. This sealed system is necessary for maintaining the correct air pressure and volume required for combustion.

Conclusion

In summary, the Compressor Air Inlet Tube (part number 3684455) plays a significant role in the air intake system by ensuring that the air from the compressor is delivered efficiently to the engine, thereby supporting optimal engine performance and reliability.

-

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.