This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3684513 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. The significance of this wiring harness lies in its ability to ensure reliable and efficient electrical performance, which is vital for the overall operation and safety of the truck.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals throughout a vehicle. It consists of multiple wires bundled together, often protected by a sheath or conduit. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured and organized method for routing electrical signals and power to different components, ensuring they function correctly and efficiently 1.

Purpose of the 3684513 Wiring Harness

This Cummins part is designed to play a role in the electrical system of a truck by connecting various electrical components to the power source. It integrates with other electrical systems, such as the engine control module, lighting systems, and sensors, to ensure they receive the necessary power and signals to operate. This integration is vital for the coordinated function of the truck’s electrical systems, contributing to its overall performance and reliability 2.

Key Features

The 3684513 Wiring Harness is characterized by several key features that enhance its functionality and durability. Its design includes a robust construction with high-quality materials that are resistant to wear, corrosion, and environmental factors. The harness is engineered to meet the demanding conditions of commercial truck operations, ensuring long-lasting performance. Additionally, it may feature unique characteristics such as specialized connectors or protective coatings to further enhance its reliability and efficiency.

Benefits

The use of the 3684513 Wiring Harness in truck operations provides several benefits. It contributes to improved reliability by ensuring stable and consistent electrical connections. This reliability is crucial for the safe and efficient operation of the truck. Additionally, the harness enhances efficiency by optimizing the routing of electrical signals and power, reducing the risk of electrical faults. Safety is also improved, as a well-maintained and properly installed wiring harness reduces the likelihood of electrical fires or malfunctions 3.

Installation Process

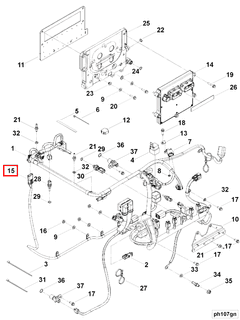

Installing the 3684513 Wiring Harness involves several steps to ensure it is correctly integrated into the truck’s electrical system. The process begins with preparing the installation area, ensuring all necessary tools and components are available. The harness is then routed through the truck, following the manufacturer’s guidelines to avoid interference with other components. Connections are made to the power source and various electrical components, with care taken to ensure all connections are secure and correctly aligned. Finally, the installation is tested to confirm proper functionality and to identify any potential issues.

Troubleshooting Common Issues

Common issues with the 3684513 Wiring Harness may include loose connections, damaged wires, or faulty connectors. Troubleshooting these issues involves a systematic approach to identify the root cause. This may include visual inspections for physical damage, testing electrical connections for continuity, and using diagnostic tools to pinpoint specific problems. Addressing these issues promptly is important to maintain the harness’s performance and to prevent more serious electrical problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3684513 Wiring Harness, regular maintenance is recommended. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the harness and its connections can prevent the buildup of dirt and debris, which may interfere with electrical conductivity. Additionally, ensuring that all connections are tight and secure can help maintain reliable electrical performance. Following the manufacturer’s maintenance guidelines is also important for preserving the harness’s integrity.

Safety Considerations

When working with the 3684513 Wiring Harness, several safety considerations should be kept in mind. Proper handling of the harness and its components is important to avoid damage. During installation and maintenance, ensuring the truck’s electrical system is de-energized can prevent electrical shocks. Additionally, following safety protocols and using appropriate personal protective equipment (PPE) can help protect against injuries. Adhering to these safety practices is important for the well-being of those working on the harness and for the safe operation of the truck.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the 3684513 Wiring Harness, which is designed to meet the high standards of performance and durability expected in commercial truck applications.

Cummins Wiring Harness 3684513 Compatibility

The Cummins Wiring Harness 3684513 is a critical component designed to ensure seamless electrical connectivity within various Cummins engine models. This wiring harness is engineered to interface with the electrical systems of the ISX CM871 engines, providing a reliable conduit for power and signals between different engine components.

In the context of the ISX CM871 engines, the wiring harness 3684513 is meticulously crafted to meet the specific electrical requirements of these engines. It ensures that all necessary electrical connections are made efficiently, supporting the engine’s operation and performance. The harness is designed to withstand the rigors of engine operation, including exposure to heat, vibration, and other environmental factors that could otherwise compromise its integrity.

The compatibility of the wiring harness 3684513 extends to ensuring that it can be integrated with other components within the engine’s electrical system. This includes connections to the engine control module (ECM), sensors, actuators, and other critical systems that rely on electrical signals to function correctly. The harness is engineered to provide a secure and stable connection, minimizing the risk of electrical faults or failures that could impact engine performance.

For the ISX CM871 engines, the wiring harness 3684513 is a vital part of the engine’s overall electrical architecture. It is designed to work in harmony with the engine’s other components, ensuring that the electrical system operates smoothly and efficiently. This compatibility is crucial for maintaining the engine’s performance and reliability over time.

Role of Part 3684513 Wiring Harness in Engine Systems

The part 3684513 Wiring Harness is an essential component that facilitates the electrical connections within engine systems. It serves as the conduit for transmitting signals and power between various engine components and the Engine Control Module (ECM).

Integration with the Engine Control Module (ECM)

The wiring harness is meticulously designed to interface with the ECM, ensuring that all necessary signals are accurately transmitted. This includes data from sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and the Manifold Absolute Pressure (MAP) sensor. These signals are vital for the ECM to make real-time adjustments to fuel injection, ignition timing, and other parameters to optimize engine performance and efficiency.

Power Distribution

Beyond signal transmission, the wiring harness is responsible for distributing power to various actuators and components. This includes the fuel injectors, ignition coils, and various solenoids. The harness ensures that these components receive the correct voltage and current, allowing them to function correctly under varying engine conditions.

Grounding and Noise Reduction

An often-overlooked function of the wiring harness is its role in providing reliable grounding paths. Proper grounding is essential for reducing electrical noise and ensuring signal integrity. The harness incorporates multiple ground points to maintain a stable electrical environment, which is particularly important in modern engines with numerous electronic components.

Safety and Redundancy

In many engine systems, the wiring harness incorporates safety features and redundancy to prevent failures. For instance, it may include fuses and relays that protect sensitive components from voltage spikes or short circuits. Additionally, some harnesses are designed with redundant paths to ensure continued operation even if a section of the wiring is damaged.

Diagnostic Capabilities

Modern wiring harnesses are equipped with diagnostic capabilities that allow for easier troubleshooting. They often include connectors for On-Board Diagnostics (OBD) systems, enabling mechanics to quickly identify and address issues. This integration streamlines the diagnostic process, reducing downtime and improving overall engine reliability.

Conclusion

In summary, the part 3684513 Wiring Harness plays a multifaceted role in engine systems, ensuring seamless communication between the ECM and various engine components, reliable power distribution, effective grounding, enhanced safety, and improved diagnostic capabilities. Its robust design and compatibility with Cummins engines make it a critical component for maintaining the performance and reliability of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.