3686755

Vibration Isolator

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3686755 Vibration Isolator is engineered to reduce the transmission of vibrations from the engine to the truck’s frame. This component enhances the operational efficiency and longevity of commercial trucks by mitigating the impact of engine vibrations. The isolator plays a role in maintaining the structural integrity of the truck and contributes to a smoother ride for the driver and passengers.

Basic Concepts of Vibration Isolators

Vibration isolators are devices designed to reduce the transmission of vibrations between mechanical components. They function by absorbing or dampening the vibrations produced by machinery, thereby preventing these vibrations from affecting other parts of the system. The principle of vibration isolation is based on the use of materials or mechanisms that can absorb vibrational energy, thus protecting sensitive equipment from the adverse effects of vibrations 1. This is particularly significant in maintaining the integrity and performance of mechanical systems over time.

Role of the 3686755 Vibration Isolator in Truck Operation

The Cummins 3686755 Vibration Isolator specifically serves to minimize the vibrations transmitted from the engine to the truck’s chassis. By doing so, it contributes to the overall performance and durability of the vehicle. This reduction in vibration helps in preserving the alignment and condition of various truck components, leading to improved operational efficiency and reduced maintenance needs 2.

Key Features

The Cummins 3686755 Vibration Isolator is characterized by its robust design and the use of high-quality materials. Its construction includes features that enhance its ability to absorb and dampen vibrations effectively. The isolator’s design is tailored to fit seamlessly within the truck’s engine system, ensuring compatibility and optimal performance. Additionally, its materials are chosen for their durability and resistance to the harsh conditions encountered in commercial truck operations.

Benefits

Utilizing the Cummins 3686755 Vibration Isolator offers several advantages. It helps in reducing wear and tear on the truck’s components by minimizing the impact of engine vibrations. This leads to a longer lifespan for the vehicle and its parts. Furthermore, by dampening vibrations, it contributes to improved driver comfort and a smoother ride. Enhanced engine performance is also a benefit, as the isolator helps maintain the engine’s operational stability.

Troubleshooting and Maintenance

Common issues with the 3686755 Vibration Isolator may include wear and tear or damage due to extreme conditions. Troubleshooting these problems involves inspecting the isolator for signs of degradation or failure and addressing any issues promptly to prevent further damage. Routine maintenance practices, such as regular inspections and replacements when necessary, are crucial for ensuring the isolator continues to perform optimally.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history rooted in innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company is committed to advancing technology and delivering reliable, high-performance components that meet the demanding needs of commercial vehicle operators.

Compatibility of Cummins 3686755 Vibration Isolator

The Cummins Vibration Isolator part number 3686755 is designed to fit a variety of Cummins engines, ensuring optimal performance and reduced noise levels. This part is engineered to isolate vibrations, thereby enhancing the longevity and efficiency of the engine systems it is used with.

ISX Series Engines

The ISX series engines, including the ISX12, ISX12/ISX11.9, ISX15, and ISX15 CM2350 X101, are compatible with the 3686755 Vibration Isolator. These engines are known for their robust performance and are widely used in heavy-duty applications.

ISX15 CM2250 SN and ISX15 CM2250

The ISX15 CM2250 SN and ISX15 CM2250 engines also benefit from the use of the 3686755 Vibration Isolator. This part is crucial for maintaining the operational integrity of these engines, particularly in environments where vibration can lead to mechanical stress and wear.

QSX Series Engines

The QSX11.9 CM2250 ECF and QSX15 CM2350 X105 engines are also compatible with the 3686755 Vibration Isolator. These engines are designed for high-performance applications, and the isolator helps in mitigating the vibrations that can occur during operation.

X Series Engines

The X series engines, including the X12 CM2350 X119B, X12 CM2670 X121B, X13 CM2670 X122B, X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B, are also suitable for the 3686755 Vibration Isolator. These engines are known for their versatility and are used in a range of applications from construction to transportation.

ISG and CM Series Engines

The ISG12 CM2880 G107 and ISX12 CM2350 X102 engines are also compatible with the 3686755 Vibration Isolator. These engines are part of Cummins’ lineup of reliable and efficient power solutions.

QSG Series Engine

The QSG12/X12 CM2350 G110 engine is also compatible with the 3686755 Vibration Isolator. This engine is designed for specific applications where reduced noise and vibration are critical.

By ensuring that the 3686755 Vibration Isolator is used with the appropriate Cummins engines, operators can maintain the performance and reliability of their equipment while minimizing the impact of vibrations on the engine and its components.

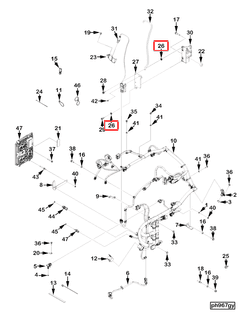

Role of Part 3686755 Vibration Isolator in Engine Systems

The Part 3686755 Vibration Isolator is instrumental in maintaining the stability and efficiency of various engine components. When integrated with the Captive Isolator Cap Screw, it ensures that vibrations are effectively dampened, preventing undue stress on the screw and enhancing the longevity of the assembly.

In conjunction with the Module and Engine Control, the Vibration Isolator plays a significant role in preserving the precision of electronic signals. By reducing mechanical vibrations, it helps maintain the accuracy of the module’s readings and the engine control’s responses, leading to smoother operation and better performance.

The Module Support benefits from the Vibration Isolator by experiencing reduced wear and tear. This support structure, when shielded from excessive vibrations, can maintain its alignment and structural integrity over extended periods, ensuring consistent module performance.

When paired with the Primer in the Fuel System, the Vibration Isolator assists in maintaining a stable fuel delivery. Vibrations can disrupt the priming process, leading to inconsistent fuel pressure. The isolator mitigates this risk, ensuring a reliable fuel supply to the engine.

The Sensor used for monitoring parameters such as nitrogen oxide emissions also relies on the Vibration Isolator. Sensors are highly sensitive to vibrations, which can lead to inaccurate readings. By isolating vibrations, the isolator ensures that the sensor provides precise data, crucial for emission control and overall engine health.

Finally, in the context of Nitrogen Oxide monitoring and control, the Vibration Isolator indirectly contributes to emission reduction efforts. By ensuring that all components, including sensors and control modules, operate within their optimal vibration-free parameters, it helps in maintaining efficient combustion processes and lower emissions.

Conclusion

The Cummins 3686755 Vibration Isolator is a critical component in the maintenance and performance of commercial truck engines. By effectively reducing vibrations, it enhances the longevity and efficiency of the engine and its components, leading to improved operational stability and reduced maintenance needs. Its compatibility with a wide range of Cummins engines ensures that it can be utilized across various applications, providing consistent performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.