3688012

Lubricating Oil Drain Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Lubricating Oil Drain Tubes

Definition and Basic Concepts

A lubricating oil drain tube is a critical component in the engine system, designed to facilitate the efficient drainage of used oil from the engine. Proper oil drainage is essential for maintaining engine health, as it ensures that contaminants and degraded oil are removed, allowing fresh oil to circulate and provide optimal lubrication. The lubricating oil drain tube plays a pivotal role in this process by providing a reliable pathway for oil to exit the engine, thereby supporting consistent engine performance and longevity 1.

Role in Engine Operation

Lubricating oil is fundamental to engine performance, reducing friction between moving parts, dissipating heat, and cleaning the engine internally. The lubricating oil drain tube aids in maintaining optimal oil levels and cleanliness by allowing for the regular and efficient removal of used oil. This ensures that the engine operates smoothly, with minimal wear and tear on its components 2.

Detailed Overview of Cummins 3688012 Lubricating Oil Drain Tube

Design and Construction

The Cummins 3688012 lubricating oil drain tube is engineered with precision, utilizing high-quality materials to ensure durability and reliability. Its design incorporates robust construction features, such as corrosion-resistant coatings and precise threading, which contribute to its effectiveness in withstanding the harsh conditions within an engine environment. The tube’s physical characteristics are tailored to fit seamlessly within Cummins engines, ensuring a secure and leak-free connection 3.

Function in Cummins Engines

Within Cummins engines, the 3688012 lubricating oil drain tube operates as a vital component in the oil drainage system. It facilitates the smooth and efficient removal of used oil from the engine, playing a crucial role in the maintenance of optimal oil levels and cleanliness. This process is essential for preserving engine performance and extending its operational lifespan.

Importance of the 3688012 Lubricating Oil Drain Tube in Truck Operations

Enhancing Engine Efficiency

The 3688012 lubricating oil drain tube significantly contributes to engine efficiency by ensuring that the engine operates with clean, fresh oil. This reduces friction and wear on engine components, leading to improved fuel consumption and overall engine performance. Efficient oil drainage also helps in maintaining the engine’s thermal efficiency, further enhancing its operational capabilities.

Maintenance and Longevity

Regular maintenance of the 3688012 lubricating oil drain tube is crucial for extending the life of the engine and reducing downtime. Proper maintenance ensures that the drain tube remains in optimal condition, free from blockages or leaks, which could otherwise lead to engine damage or failure. By adhering to recommended maintenance schedules, truck operators can ensure the longevity and reliability of their engines.

Troubleshooting and Maintenance of the 3688012 Lubricating Oil Drain Tube

Common Issues and Solutions

Common problems associated with the 3688012 lubricating oil drain tube include blockages, leaks, and corrosion. To address these issues, a step-by-step troubleshooting guide can be followed:

- Inspect the drain tube for any visible signs of damage or corrosion.

- Check for blockages by attempting to drain the oil; if the flow is restricted, the tube may be clogged.

- For leaks, ensure that all connections are tight and free from debris.

- If corrosion is detected, consider replacing the drain tube to prevent further damage.

Maintenance Best Practices

Recommended maintenance procedures for the 3688012 lubricating oil drain tube include regular inspection during oil changes, cleaning the tube and its connections to remove any buildup, and ensuring that all seals and connections are intact. Additionally, following the manufacturer’s guidelines for maintenance intervals will help in ensuring the longevity and reliability of the component.

Cummins: A Leader in Engine Technology

Company Overview

Cummins Inc. has a rich history of innovation and excellence in the engine industry. Founded in 1919, Cummins has grown to become a global leader in the design, manufacture, and distribution of engines and related technologies. The company’s reputation for producing high-quality engine components is well-established, making it a trusted name among mechanics and engineers.

Commitment to Innovation and Quality

Cummins’ dedication to innovation and quality is evident in its product lineup, including the 3688012 lubricating oil drain tube. This component exemplifies Cummins’ commitment to excellence, offering reliable performance and durability that meets the demanding requirements of heavy-duty applications.

Expert Insights and Best Practices

Insights from Industry Experts

Industry experts emphasize the critical role of the 3688012 lubricating oil drain tube in maintaining engine health and performance. Real-world examples illustrate how proper maintenance and timely replacement of this component can significantly impact engine reliability and efficiency.

Best Practices for Truck Operators and Mechanics

For truck operators and mechanics, the effective use and maintenance of the 3688012 lubricating oil drain tube are paramount. Recommendations include adhering to regular maintenance schedules, inspecting the drain tube during each oil change, and addressing any issues promptly to ensure optimal engine performance and reliability. By following these best practices, operators can maximize the efficiency and longevity of their engines.

Cummins Engine Compatibility with Lubricating Oil Drain Tube Part 3688012

The Cummins lubricating oil drain tube part number 3688012 is designed to fit a variety of Cummins engines, ensuring efficient oil drainage and maintenance. This part is integral to the engine’s lubrication system, facilitating the removal of used oil from the engine’s sump. Below is a detailed look at the compatibility of this part with specific engine models.

ISX15 Series Engines

The ISX15 CM2250 and ISX15 CM2350 X101 engines are part of the ISX15 series, known for their robust performance and reliability. The lubricating oil drain tube part 3688012 is engineered to fit seamlessly with these engines, ensuring optimal oil flow and preventing contamination.

QSX15 Series Engines

The QSX15 CM2250 and QSX15 CM2250 ECF engines are also compatible with the part 3688012. This tube is designed to handle the specific oil drainage requirements of these models, ensuring that the lubrication system operates efficiently.

Enhanced Efficiency Models

The QSX15 CM2350 X105 engine, which is part of the enhanced efficiency models, is another engine that benefits from the use of the lubricating oil drain tube part 3688012. This part is specifically designed to meet the stringent requirements of these high-performance engines.

Advanced Performance Models

The X15 CM2350 X116B engine, known for its advanced performance, also integrates the lubricating oil drain tube part 3688012. This part ensures that the engine’s lubrication system functions smoothly, contributing to the overall reliability and longevity of the engine.

By ensuring compatibility with these engines, the lubricating oil drain tube part 3688012 plays a crucial role in maintaining the performance and longevity of Cummins engines.

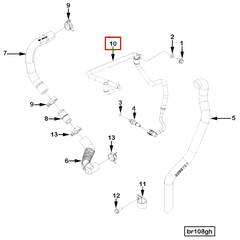

Role of Part 3688012 Lubricating Oil Drain Tube in Engine Systems

The lubricating oil drain tube, identified as part 3688012, is an essential component in the maintenance and operation of various engine systems. Its primary function is to facilitate the efficient drainage of lubricating oil from the crankcase, ensuring that the engine operates smoothly and that oil levels are maintained within optimal ranges.

Integration with the Crankcase

The crankcase is a vital part of the engine, housing the crankshaft and connecting rods. It is imperative that the crankcase maintains a clean and lubricated environment to ensure the longevity and efficiency of these components. The lubricating oil drain tube plays a significant role here by allowing for the periodic removal of old or contaminated oil, which can accumulate sludge and debris over time. This process helps in preserving the integrity of the crankcase and its internal components.

Interaction with the Breather System

A well-functioning breather system is essential for maintaining the correct pressure within the crankcase. The crankcase breather allows gases produced during combustion to escape, preventing the buildup of pressure that could lead to leaks or damage. The lubricating oil drain tube works in conjunction with this system by ensuring that the oil level does not rise to a point where it could be drawn into the breather, which would contaminate the air intake system and reduce engine efficiency.

Plumbing Considerations

In the context of engine plumbing, the lubricating oil drain tube is a key component that connects to the oil pan or sump where the lubricating oil is stored. Proper plumbing ensures that the oil can be drained efficiently and without spillage, which is important for both maintenance procedures and environmental considerations. The tube must be correctly installed to avoid any kinks or obstructions that could impede the flow of oil during drainage.

Maintenance and Operational Efficiency

Regular maintenance of the lubricating oil is fundamental to engine health. The lubricating oil drain tube simplifies the oil change process, allowing for quick and clean drainage. This efficiency is particularly important in high-performance or high-stress engine applications where frequent oil changes are necessary to maintain optimal lubrication and prevent engine wear.

Conclusion

In summary, the lubricating oil drain tube (part 3688012) is a component that enhances the functionality and maintenance of engine systems by ensuring efficient oil drainage, supporting the breather system, and contributing to the overall plumbing integrity of the engine. Proper maintenance and timely replacement of this part are crucial for maintaining engine health, efficiency, and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.