This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

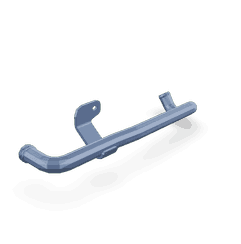

The Compressor Air Inlet Tube, identified by part number 3691510, is a component manufactured by Cummins, a prominent entity in the commercial truck industry. This tube is integral to the operation of heavy-duty trucks, facilitating the intake of air into the compressor and contributing to the overall efficiency and performance of the engine.

Basic Concepts

The operation of a Compressor Air Inlet Tube is grounded in the fundamental principles of air compression. This component plays a role in directing air into the compressor, where it is pressurized before entering the engine’s combustion chamber. The efficiency of this process is vital for optimal engine performance, as it ensures that the engine receives a consistent and adequate supply of pressurized air 1.

Purpose and Function

The primary role of the Compressor Air Inlet Tube is to facilitate the intake of air into the compressor. By providing a direct and unobstructed pathway for air to enter the compressor, this tube contributes to efficient engine function. It ensures that the compressor receives a steady flow of air, which is crucial for maintaining the engine’s performance under various operating conditions 2.

Key Features

The 3691510 Compressor Air Inlet Tube is characterized by several key features that enhance its performance and durability. Its design is engineered to withstand the high pressures and temperatures associated with the air compression process. The materials used in its construction are selected for their strength and resistance to wear, ensuring long-term reliability. Additionally, the tube may feature unique attributes such as reinforced sections or specialized coatings to further improve its performance 3.

Benefits

The advantages provided by the Compressor Air Inlet Tube include improved engine efficiency and reliability. By ensuring a consistent supply of pressurized air to the engine, this component contributes to more efficient combustion, which can lead to better fuel economy. Additionally, its robust construction and design help to minimize the risk of failures, reducing maintenance costs and downtime for fleet operators.

Installation and Integration

Proper installation of the Compressor Air Inlet Tube is crucial for ensuring seamless integration with the truck’s engine system. The installation process may require specific preparations, tools, and steps to ensure that the tube is correctly positioned and securely fastened. Following the manufacturer’s guidelines is recommended to achieve optimal performance and longevity of the component.

Troubleshooting and Maintenance

Identifying common issues related to the Compressor Air Inlet Tube can be facilitated through regular inspections and diagnostic procedures. Maintenance practices such as cleaning the tube to remove any debris or obstructions, checking for signs of wear or damage, and ensuring all connections are secure can help prolong its service life and ensure optimal performance.

Performance Impact

The Compressor Air Inlet Tube influences the overall performance of the truck in several ways. It plays a role in enhancing fuel efficiency by ensuring that the engine receives a consistent supply of pressurized air. This can also contribute to increased power output and reduced emissions, as efficient combustion is a key factor in these areas.

Safety Considerations

When handling, installing, or maintaining the Compressor Air Inlet Tube, it is important to adhere to safety protocols and considerations to prevent accidents. This includes ensuring that the engine is turned off and cooled down before beginning any work, using appropriate personal protective equipment, and following all manufacturer guidelines to ensure compliance with industry standards.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range is designed to meet the demanding requirements of heavy-duty applications, ensuring reliability and performance in various operating conditions.

Compatibility of Compressor Air Inlet Tube Part 3691510 with Cummins Engines

The Compressor Air Inlet Tube part number 3691510, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. Specifically, this part is compatible with the following engine models:

- X15 CM2350 X123B

- X15 CM2350 X116B

These engines share a common architecture that allows the part 3691510 to be used interchangeably. The design ensures that the air inlet tube fits perfectly, providing optimal airflow and efficiency.

Additionally, the part is also compatible with:

- X15 CM2450 X134B

While this engine model differs slightly from the X15 CM2350 series, the design of the Compressor Air Inlet Tube part 3691510 is versatile enough to accommodate the differences, ensuring a proper fit and function.

This compatibility across these engine models highlights the robustness and adaptability of the part, making it a reliable choice for maintenance and repairs.

Role of Part 3691510 Compressor Air Inlet Tube in Engine Systems

The Part 3691510 Compressor Air Inlet Tube is an integral component in the efficient operation of engine systems, particularly in the context of compressor air inlet arrangements and plumbing. This component is designed to facilitate the smooth and uninterrupted flow of air into the compressor, ensuring optimal performance and reliability of the engine system.

In the compressor air inlet arrangement, the Compressor Air Inlet Tube serves as a conduit that directs ambient air from the surroundings into the compressor. This air, once compressed, plays a significant role in the combustion process, contributing to the engine’s power output and efficiency. The design and placement of the tube are engineered to minimize turbulence and ensure a steady airflow, which is essential for maintaining consistent compressor performance.

In terms of plumbing, the Compressor Air Inlet Tube is connected to various components within the engine system. It interfaces with the air filter housing, ensuring that the air entering the compressor is clean and free from contaminants. This connection is vital for protecting the compressor blades and other internal components from damage due to foreign particles. Additionally, the tube may be linked to sensors that monitor air pressure and temperature, providing valuable data for the engine control unit to make real-time adjustments for optimal performance.

The integration of the Compressor Air Inlet Tube within the compressor air inlet system also involves its interaction with other components such as the intercooler (if present) and the throttle body. The tube’s role in these interactions is to maintain a consistent and regulated airflow, which is crucial for the efficient operation of these components. For instance, in turbocharged engines, the tube helps in managing the boost pressure by ensuring that the compressor receives the correct amount of air, thereby enhancing the engine’s responsiveness and power delivery.

Overall, the Compressor Air Inlet Tube is a key element in the engine’s air induction system, playing a significant role in the performance, efficiency, and reliability of the engine. Its proper installation and maintenance are essential for ensuring that the engine operates within its designed parameters, delivering the expected power output and longevity.

Conclusion

The Compressor Air Inlet Tube, part number 3691510, is a critical component in the efficient operation of Cummins engines. Its role in facilitating the intake of air into the compressor ensures optimal engine performance and reliability. The tube’s design and construction are tailored to withstand the demanding conditions of heavy-duty applications, contributing to improved fuel efficiency, increased power output, and reduced emissions. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the benefits of this component and ensuring the longevity of the engine system.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.