This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

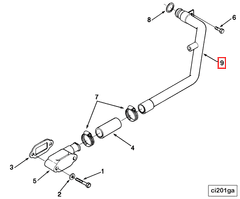

The Compressor Air Inlet Tube, identified by Part #3819462, is a component manufactured by Cummins, a leading name in the commercial truck industry. This part is integral to the air compressor system of heavy-duty trucks, facilitating the intake, filtration, and delivery of air to the compressor. Its role in ensuring the efficient operation of the truck’s air compressor system underscores its significance in maintaining overall engine performance and reliability 2.

Basic Concepts of Compressor Air Inlet Tubes

Compressor air inlet tubes are designed to channel air from the external environment into the air compressor system. Within the broader context of truck engine operation, these tubes play a role in the air intake process by ensuring that the compressor receives a steady and clean supply of air. This air is vital for the compressor’s function, which in turn supports various engine operations, including braking systems and pneumatic tools 1.

Role of the Compressor Air Inlet Tube in Truck Operation

The Compressor Air Inlet Tube (Part #3819462) contributes to the efficient operation of a truck’s air compressor system in several ways. It facilitates the intake of air, which is then filtered to remove contaminants before being delivered to the compressor. This process ensures that the compressor operates with clean air, which is crucial for its efficiency and longevity. The tube’s design and placement within the system are optimized to minimize air resistance and maximize airflow, thereby supporting the compressor’s performance 2.

Key Features of the Cummins Compressor Air Inlet Tube

The Cummins Compressor Air Inlet Tube is characterized by several key features that enhance its durability and efficiency. Constructed from high-quality materials, it is designed to withstand the harsh conditions typical of heavy-duty truck environments. Its design includes elements that reduce turbulence and improve airflow, contributing to the overall efficiency of the air compressor system. Additionally, the tube may feature unique attributes such as reinforced sections or specialized coatings that further enhance its performance and longevity 2.

Benefits of Using the Cummins Compressor Air Inlet Tube

Utilizing the Cummins Compressor Air Inlet Tube offers several advantages. It contributes to improved air compressor performance by ensuring a clean and steady air supply. Its durable construction reduces the likelihood of failures, leading to enhanced reliability. Furthermore, the efficient design of the tube can result in potential cost savings through reduced maintenance needs and extended component lifespan 2.

Troubleshooting and Maintenance Suggestions

Common issues with the Compressor Air Inlet Tube may include blockages, leaks, or damage from environmental factors. Diagnostic steps for identifying problems can involve visual inspections, pressure tests, and performance assessments of the air compressor system. Maintenance practices to ensure longevity and optimal performance include regular cleaning to remove contaminants, checking for signs of wear or damage, and ensuring all connections are secure. Prompt attention to any issues can prevent more significant problems and maintain the efficiency of the air compressor system 2.

Integration with Cummins Engine Systems

The Compressor Air Inlet Tube (Part #3819462) is designed to integrate seamlessly with Cummins engine systems. Its compatibility with various Cummins engine models ensures that it can be relied upon to support the air compressor system across a range of applications. By maintaining a clean and efficient air supply to the compressor, the tube plays a role in supporting overall engine health and performance 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation and quality in the commercial truck industry. Its commitment to advancing technology and improving engine efficiency is evident in its wide range of products, including the Compressor Air Inlet Tube. Cummins’ focus on quality and performance ensures that its components, like the Compressor Air Inlet Tube, are designed to meet the demanding requirements of heavy-duty truck applications 2.

Compatibility of the Cummins Compressor Air Inlet Tube

The Cummins Compressor Air Inlet Tube, part number 3819462, is designed to fit seamlessly with several Cummins engine models. This part is essential for ensuring the efficient operation of the engine’s air intake system. Below is a detailed overview of the compatibility of this part with various Cummins engines:

ISM CM570

The ISM CM570 engine benefits from the precise fit of the Compressor Air Inlet Tube. This part ensures that the air intake system operates efficiently, contributing to the overall performance and reliability of the engine.

L10 Engines

- L10 CELECT

- L10 MECHANICAL

Both the L10 CELECT and L10 MECHANICAL engines are designed to integrate the Compressor Air Inlet Tube without any modifications. This compatibility ensures that the air intake system functions optimally, supporting the engine’s performance and efficiency.

M11 Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines, including the CELECT, CELECT PLUS, and MECHANICAL variants, are all compatible with the Compressor Air Inlet Tube. This part is engineered to fit these engines perfectly, ensuring that the air intake system operates at peak efficiency. The precise fitment of this component is crucial for maintaining the performance and reliability of the M11 engines.

QSM11 CM570

The QSM11 CM570 engine is another model that is designed to work seamlessly with the Compressor Air Inlet Tube. This part is essential for ensuring that the air intake system functions correctly, contributing to the overall efficiency and performance of the engine.

By ensuring that the Compressor Air Inlet Tube fits correctly with these engines, Cummins maintains the high standards of performance and reliability that their customers expect. This compatibility is a testament to Cummins’ commitment to providing high-quality, durable, and efficient engine components 2.

Role of the Compressor Air Inlet Tube in Engine Systems

The Compressor Air Inlet Tube, designated as part 3819462, is an essential component in the arrangement of various engine systems. Its primary function is to facilitate the smooth and efficient flow of air into the compressor section of the engine.

In the context of the compressor air inlet, this tube serves as a direct conduit, ensuring that the air entering the system is free from contaminants and obstructions. This is vital for maintaining the performance and longevity of the compressor, as clean and unobstructed airflow is necessary for optimal operation.

The inlet arrangement benefits significantly from the presence of the Compressor Air Inlet Tube. By providing a dedicated pathway for air, it helps in stabilizing the airflow dynamics within the engine. This stabilization is important for consistent compressor performance, as fluctuations in airflow can lead to inefficiencies and potential damage.

Furthermore, the integration of the Compressor Air Inlet Tube within the compressor air system enhances the overall reliability of the engine. It acts as a buffer, reducing the impact of external environmental factors on the compressor. This is particularly important in high-stress environments where the engine is subjected to varying conditions.

In summary, the Compressor Air Inlet Tube (part 3819462) plays a significant role in the efficient and reliable operation of engine systems by ensuring a steady and clean supply of air to the compressor, thereby contributing to the overall performance and durability of the engine 1.

Conclusion

The Compressor Air Inlet Tube (Part #3819462) is a critical component in the air compressor system of heavy-duty trucks, ensuring efficient and reliable operation. Its role in facilitating the intake, filtration, and delivery of air to the compressor underscores its importance in maintaining overall engine performance and reliability. The tube’s design and features contribute to its durability and efficiency, offering benefits such as improved air compressor performance, enhanced reliability, and potential cost savings. Regular maintenance and prompt troubleshooting are essential for ensuring the longevity and optimal performance of this part. The seamless integration of the Compressor Air Inlet Tube with various Cummins engine models further highlights its significance in supporting engine health and performance 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.