This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

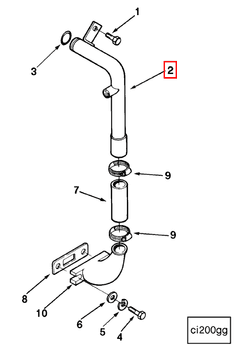

The Cummins 3819470 Compressor Air Inlet Tube is a component designed for use in heavy-duty trucks. It serves a specific role within the truck’s air compressor system, facilitating the intake of air necessary for the compressor’s operation. This part is integral to maintaining the efficiency and performance of the truck’s air system, which is vital for various functions including braking and suspension 1.

Function and Operation

The Compressor Air Inlet Tube operates as a conduit for air entering the truck’s air compressor. Air is drawn in through the inlet tube, where it is then compressed and stored in reservoirs for use in the vehicle’s air brake system and other pneumatic applications. The design of the tube ensures a smooth and uninterrupted flow of air from the environment into the compressor, which is crucial for the compressor’s ability to generate the required air pressure 2.

Purpose of the Compressor Air Inlet Tube

The primary role of the Compressor Air Inlet Tube is to provide a dedicated pathway for air to enter the compressor. By ensuring a consistent and efficient air intake, the tube contributes to the compressor’s ability to maintain optimal performance. This, in turn, supports the overall functionality of the truck’s air system, which is dependent on a reliable supply of compressed air 3.

Key Features

The Cummins 3819470 Compressor Air Inlet Tube is constructed from durable materials that are resistant to the rigors of heavy-duty truck operation. Its design includes features that enhance air flow efficiency, such as a smooth interior surface to minimize turbulence and resistance. Additionally, the tube may incorporate elements that protect against contaminants, ensuring that only clean air enters the compressor.

Benefits

The benefits of the Compressor Air Inlet Tube include improved air flow to the compressor, which can lead to enhanced compressor efficiency. This can potentially contribute to better fuel economy, as a more efficient compressor may require less power to operate. Furthermore, by ensuring clean air intake, the tube can help reduce the frequency of compressor maintenance, leading to lower overall maintenance costs.

Installation Considerations

Proper installation of the Compressor Air Inlet Tube is important to ensure it functions as intended. This includes correct fitting and alignment within the truck’s air compressor system. Attention to these details during installation helps to maintain the integrity of the air flow path and ensures that the compressor receives the necessary air supply for efficient operation.

Troubleshooting Common Issues

Common issues with the Compressor Air Inlet Tube may include leaks, blockages, or physical damage. Troubleshooting these problems involves inspecting the tube for signs of wear or damage, checking for proper alignment and fit within the system, and ensuring that there are no obstructions in the air flow path. Addressing these issues promptly can help maintain the performance of the truck’s air system.

Maintenance Tips

Regular maintenance of the Compressor Air Inlet Tube is important for ensuring its longevity and reliable performance. This includes periodic cleaning to remove any accumulated dirt or debris, inspection for signs of wear or damage, and replacement when necessary. Following these maintenance practices can help prevent issues with the air compressor system and ensure consistent performance.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a history of producing diesel engines and related components. The company is known for its commitment to quality and innovation in the automotive industry. Cummins’ products, including the 3819470 Compressor Air Inlet Tube, are designed with a focus on durability, performance, and compatibility with a wide range of heavy-duty truck applications.

Compatibility with Cummins Engines

The Compressor Air Inlet Tube, identified by part number 3819470, is a critical component in the air intake system of several Cummins engines. This part is designed to ensure that the engine receives a consistent and uncontaminated air supply, which is essential for optimal performance and efficiency.

ISM CM570

The ISM CM570 engine benefits from the precise fit and function of the Compressor Air Inlet Tube. This part is integral in maintaining the air quality entering the engine, which is crucial for the engine’s electronic control system.

L10 Engines

For the L10 engines, both the L10 CELECT and L10 MECHANICAL variants, the Compressor Air Inlet Tube plays a vital role in the air intake process. The design of this part ensures that the air entering the engine is free from contaminants, which is particularly important for the mechanical variant where precise air management can affect performance.

M11 Engines

The M11 CELECT and M11 CELECT PLUS engines also rely on the Compressor Air Inlet Tube for efficient air intake. This part is engineered to work seamlessly with the electronic control systems of these engines, ensuring that the air entering the engine is clean and at the correct pressure.

Similarly, the M11 MECHANICAL engine uses this part to maintain the integrity of the air intake system. The design of the Compressor Air Inlet Tube is such that it complements the mechanical nature of this engine, providing a reliable and consistent air supply.

QSM11 CM570

The QSM11 CM570 engine also incorporates the Compressor Air Inlet Tube in its air intake system. This part is designed to work with the engine’s electronic control system, ensuring that the air entering the engine is of high quality and at the correct pressure.

Understanding the Role of 3819470 in Engine Systems

In the intricate network of an engine system, the 3819470 Compressor Air Inlet Tube serves as a vital conduit for the efficient operation of the compressor. This component is integral to the air intake process, ensuring that the compressor receives a steady and uncontaminated supply of air.

Integration with Compressor Air Inlet

The Compressor Air Inlet is the gateway through which ambient air enters the compressor. The 3819470 Compressor Air Inlet Tube is meticulously designed to connect seamlessly with this inlet, forming a secure and airtight seal. This connection is essential for maintaining the integrity of the air supply, preventing any leaks that could compromise compressor performance.

Connection to Air Compressor Inlet

The Air Compressor Inlet is another key component where the 3819470 Compressor Air Inlet Tube plays a significant role. This tube ensures a direct and unobstructed path for air to flow from the external environment into the compressor. The design of the tube minimizes turbulence and resistance, allowing for optimal airflow and efficiency.

Role in the Overall Arrangement

Within the engine system, the arrangement of components is meticulously planned to maximize performance and reliability. The 3819470 Compressor Air Inlet Tube is strategically positioned to facilitate the smooth transition of air from the external environment to the compressor. Its painted surface not only enhances durability but also aids in identifying the component during maintenance procedures.

Ensuring a Painted Air Compressor Tube

The Painted Air Compressor Tube aspect of 3819470 is not merely aesthetic. The paint serves multiple purposes, including corrosion resistance and ease of identification. This protective coating ensures that the tube remains functional over extended periods, even in harsh operating environments.

Conclusion

In summary, the 3819470 Compressor Air Inlet Tube is a fundamental component in the engine system, facilitating the efficient intake of air into the compressor. Its precise connection with the Compressor Air Inlet and Air Compressor Inlet, along with its durable painted surface, underscores its importance in maintaining the overall performance and reliability of the engine system.

-

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ -

Konrad Reif, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems (Springer Vieweg, 2014).

↩ -

Michael Hilgers, Entire Vehicle: Second Edition (Springer Nature, 2023).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.