This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

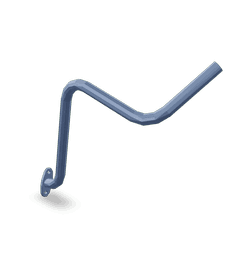

The Tur Oil Drain Tube, part number 3820428, manufactured by Cummins, is a vital component in the maintenance of heavy-duty trucks. This part facilitates the efficient drainage of oil from the engine, ensuring the vehicle’s operation and maintenance are conducted smoothly. Cummins, a leader in the automotive industry, ensures this part meets the stringent standards required for heavy-duty applications 1.

Function and Operation

The Tur Oil Drain Tube serves as a conduit within the oil drainage system of a truck engine. It allows for the smooth and controlled release of oil during maintenance, connecting to the engine’s oil pan to provide a safe and efficient pathway for oil to exit the system. This process is essential for regular maintenance routines, ensuring old oil is effectively removed and replaced, which is fundamental for maintaining engine health and performance 2.

Key Features

This Cummins part is constructed from durable materials designed to withstand the harsh conditions of heavy-duty truck engines. Its design includes a robust connection mechanism that ensures a secure fit within the engine system, minimizing the risk of leaks. Additionally, the tube’s design allows for easy installation and removal, facilitating routine maintenance tasks 3.

Benefits

Utilizing the Tur Oil Drain Tube offers several advantages. It contributes to improved engine performance by ensuring efficient oil drainage, which is crucial for maintaining the engine’s lubrication system. The tube’s design also aids in reducing the time required for maintenance tasks, allowing for quicker turnaround times. Furthermore, by facilitating effective oil drainage, the tube plays a role in extending the engine’s lifespan, underscoring its value in heavy-duty truck maintenance.

Installation and Usage

Proper installation of the Tur Oil Drain Tube involves several steps to ensure a secure and leak-free connection. Preparatory steps include ensuring the engine is cool and the oil has been allowed to settle, minimizing the risk of spillage. The fitting procedure requires careful alignment with the engine’s oil pan, followed by a thorough check to confirm the connection is secure. Regular use of the tube in maintenance schedules is recommended to ensure the engine’s oil system remains in optimal condition.

Troubleshooting and Maintenance

Common issues with oil drain tubes can include leaks or blockages, which may arise from improper installation or wear over time. Identifying these issues early is important for maintaining the efficiency of the oil drainage system. Maintenance tips for the Tur Oil Drain Tube include regular inspections for signs of wear or damage, and cleaning the tube and its connections to prevent buildup that could impede its function. These practices help ensure the tube remains effective throughout its service life.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a provider of reliable and innovative solutions for the automotive industry. The company’s commitment to quality and innovation is evident in its wide range of products, designed to meet the demanding requirements of various applications, including heavy-duty trucks. Cummins’ emphasis on using manufacturer-recommended parts underscores its dedication to ensuring optimal performance and safety in its products.

Tur Oil Drain Tube for Cummins Engines

The Tur Oil Drain Tube, part number 3820428, manufactured by Cummins, is a critical component designed to facilitate the drainage of lubricating oil from various engine systems. This part is integral to maintaining the operational integrity of the engines by ensuring that oil is effectively removed from the turbocharger and other related components.

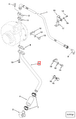

Application in L10 Engines

The Tur Oil Drain Tube is compatible with the L10 GAS and L10 MECHANICAL engines. In these engines, the part plays a pivotal role in the oil management system, ensuring that oil is efficiently drained from the turbocharger. This is essential for preventing oil accumulation, which can lead to overheating and potential damage to the turbocharger and associated parts.

Grouping by Engine Type

- L10 GAS: This engine variant utilizes the Tur Oil Drain Tube to manage oil flow from the turbocharger, ensuring that the system operates smoothly and efficiently.

- L10 MECHANICAL: Similarly, in the L10 MECHANICAL engine, the part is crucial for maintaining the oil drainage process, contributing to the overall reliability and performance of the engine.

By integrating the Tur Oil Drain Tube into the design of these engines, Cummins ensures that the oil management system is robust and capable of handling the demands of high-performance applications. This part is a testament to Cummins’ commitment to providing reliable and durable components for their engines.

Role of Part 3820428 Tur Oil Drain Tube in Engine Systems

The 3820428 Tur Oil Drain Tube is an essential component in the maintenance and operation of turbocharged engine systems. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Plumbing Systems

In the context of engine plumbing, the Tur Oil Drain Tube is connected to the oil return lines. This connection allows for the continuous circulation of oil, which is vital for the cooling and lubrication of the turbocharger’s moving parts. The tube directs the used oil back to the sump or oil pan, where it can be filtered and recirculated. This process is integral to maintaining the integrity of the oil, preventing contamination, and ensuring that the oil’s viscosity remains consistent.

Interaction with the Turbocharger

The turbocharger relies on a steady supply of clean oil for its operation. The Tur Oil Drain Tube plays a significant role in this by ensuring that any excess or contaminated oil is efficiently removed from the turbocharger. This drainage is essential for preventing oil buildup, which can lead to increased temperatures and potential damage to the turbocharger’s bearings and seals.

By maintaining a clean oil supply, the Tur Oil Drain Tube contributes to the turbocharger’s ability to compress intake air effectively, thereby enhancing engine performance and reliability. The efficient drainage also helps in reducing the risk of oil leaks, which can be detrimental to both the turbocharger and the overall engine system.

Conclusion

In summary, the 3820428 Tur Oil Drain Tube is a key component in the maintenance of turbocharged engine systems, ensuring that the lubrication and cooling processes are maintained at optimal levels. Its integration with the engine’s plumbing and direct interaction with the turbocharger underscore its importance in the overall functionality and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.