This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

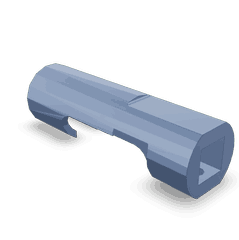

The Cummins 3822747 Hexagon Sensor Socket is a specialized component designed for use in commercial truck maintenance and operation. This part facilitates the interaction between sensors and the truck’s engine system, playing a significant role in ensuring the accurate collection of data and maintaining optimal system performance. Its design and functionality are tailored to meet the demanding requirements of commercial trucking environments.

Purpose and Function

This Cummins part serves as an interface between sensors and various components within the engine system of commercial trucks. By providing a secure and precise connection, it enables sensors to accurately monitor engine parameters such as temperature, pressure, and other critical metrics. This accurate data collection is vital for the engine control unit (ECU) to make informed adjustments, thereby enhancing overall engine performance and efficiency 1.

Key Features

The Cummins 3822747 Hexagon Sensor Socket is characterized by its hexagonal design, which offers a robust and secure fit for sensors. Constructed from high-quality materials, it is engineered to withstand the harsh conditions typical of commercial trucking operations. Its unique attributes include enhanced durability, resistance to corrosion, and a design that minimizes the risk of sensor misalignment, contributing to reliable and consistent performance 2.

Benefits

Utilizing the Cummins 3822747 Hexagon Sensor Socket offers several advantages. It contributes to improved sensor accuracy, which is crucial for precise engine management. Its durable construction ensures longevity, reducing the frequency of replacements and associated costs. Additionally, by facilitating efficient maintenance practices, it can lead to potential cost savings for fleet operators.

Installation and Usage

Proper installation of the Cummins 3822747 Hexagon Sensor Socket involves ensuring a clean and dry connection point on the engine. The socket should be aligned correctly with the sensor before being securely fastened. It is important to follow manufacturer guidelines to ensure optimal performance and longevity. Regular inspections and maintenance checks are recommended to verify the integrity of the connection and the socket’s condition.

Troubleshooting and Maintenance

Common issues with the Cummins 3822747 Hexagon Sensor Socket may include sensor misalignment or corrosion. Troubleshooting steps involve checking the alignment and condition of the socket and sensor, cleaning any corrosion, and ensuring a secure fit. Regular maintenance, such as inspecting for signs of wear or damage and cleaning the connection points, can help prolong the lifespan of the socket and ensure consistent performance.

Safety Considerations

When working with the Cummins 3822747 Hexagon Sensor Socket, it is important to observe safety guidelines. This includes ensuring the engine is off and cool before beginning any work, using appropriate personal protective equipment (PPE), and following all manufacturer instructions for installation and maintenance. Proper handling and care of the socket and sensors are crucial to prevent accidents and ensure user safety.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s focus on customer satisfaction is evident in the design and manufacturing of its automotive components, including the Cummins 3822747 Hexagon Sensor Socket.

Conclusion

The Cummins 3822747 Hexagon Sensor Socket is a vital component in the maintenance and operation of commercial trucks, ensuring accurate sensor data collection and enhancing engine performance. Its robust design, durability, and ease of maintenance make it a valuable asset for fleet operators, contributing to efficient and reliable truck operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.