This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Feeler Gage .015" (Part #3871428) is a specialized tool designed for precision measurement in the maintenance and operation of commercial trucks. This tool is integral to ensuring the proper functioning of various components within a truck’s engine, particularly in the context of valve clearance and other critical measurements.

Basic Concepts of Feeler Gages

A feeler gage is a thin, flat strip of metal or other material used to measure small gaps or clearances between mechanical parts. It operates on the principle of gauging, where the thickness of the gage is compared to the space between components. Feeler gages are widely used in mechanical and automotive fields for tasks requiring precise clearance measurements, such as valve adjustments in engines 1.

Purpose of the Cummins Feeler Gage .015"

The Cummins Feeler Gage .015" is specifically designed to measure gaps of .015 inches. In the maintenance of commercial trucks, this tool plays a role in ensuring the correct valve clearance, which is vital for the engine’s performance and longevity. Proper valve clearance allows for efficient combustion and reduces the risk of engine damage due to improper valve operation 2.

Key Features

The Cummins Feeler Gage .015" is characterized by its precise measurement capability, allowing for accurate gap measurements to within .015 inches. Its construction is durable, making it suitable for the rigors of heavy-duty applications. The design of the gage ensures ease of use, with clear markings and a robust build that withstands frequent use in demanding environments.

Benefits of Using the Cummins Feeler Gage .015"

Utilizing the Cummins Feeler Gage .015" in truck maintenance offers several advantages. Its accuracy in measurements ensures that components are adjusted to the manufacturer’s specifications, promoting optimal engine performance. The ease of use and reliability of the gage contribute to efficient maintenance procedures, reducing downtime and enhancing the overall reliability of the truck.

Troubleshooting and Maintenance Suggestions

Common issues with feeler gages may include bending or inaccurate measurements due to wear. To address these, regular inspection of the gage for damage is recommended. Maintenance practices such as cleaning the gage after use and storing it in a protective case can help preserve its accuracy and longevity. If a gage becomes bent or shows signs of wear, it should be replaced to ensure continued precision in measurements.

Application in Truck Maintenance

The Cummins Feeler Gage .015" is utilized in various maintenance procedures for commercial trucks, particularly in checking and adjusting valve clearances. This process is crucial for maintaining engine efficiency and preventing damage. The gage is also used in other measurements where precise clearances are required, ensuring all components operate within specified tolerances.

Safety Considerations

When using the Cummins Feeler Gage .015", it is important to observe safety practices to ensure both the user’s safety and the accuracy of measurements. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before making adjustments, and handling the gage with care to avoid damage. Accurate measurements are crucial for the safe and efficient operation of the truck, underscoring the importance of careful and correct use of the feeler gage.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality and innovation in the commercial truck industry. The company’s extensive product range and reputation for reliability make it a preferred choice for truck manufacturers and maintenance professionals alike.

Role of Part 3871428 Feeler Gage .015" in Engine Systems

When working with an engine brake kit, precision is key to ensuring optimal performance and longevity of the engine components. This Cummins part is an indispensable tool in this regard, facilitating accurate measurements that are vital for the proper functioning of the engine brake system.

Valve Clearance Adjustment

One of the primary applications of the Feeler Gage .015" is in the adjustment of valve clearances. In an engine brake kit, maintaining the correct valve clearance is essential for efficient operation. The Feeler Gage allows mechanics to measure the gap between the valve stem and the rocker arm or tappet. A .015" thickness is often used during the initial setup or when fine-tuning the engine to ensure that the valves open and close at the precise moments required for effective braking.

Piston Ring Gap Measurement

Another significant use of the Feeler Gage .015" is in measuring the piston ring gap. In an engine equipped with an engine brake kit, the piston rings must fit snugly within the cylinder bore to create an effective seal. The Feeler Gage helps in verifying that the gap between the ends of the piston ring is within the manufacturer’s specified tolerances, ensuring that compression is maintained and that the engine brake functions as intended.

Clearance in Exhaust Brake Systems

Engine brake kits often include exhaust brake systems that require specific clearances for components such as the butterfly valve or the actuator arm. The Feeler Gage .015" is used to measure these clearances, ensuring that there is no undue friction or binding that could impair the operation of the exhaust brake. Proper clearances are vital for the rapid opening and closing of the butterfly valve, which is crucial for the engine brake’s effectiveness in decelerating the vehicle.

Turbocharger Turbine Housing Gap

In turbocharged engines fitted with an engine brake kit, the turbocharger’s turbine housing may require specific clearances to function optimally. The Feeler Gage .015" can be employed to measure the gap between the turbine wheel and the housing, ensuring that there is adequate space for the turbine to spin freely without contacting the housing. This measurement is particularly important in high-performance applications where even minor clearance issues can lead to significant performance drops or component failure.

Gasket Thickness Verification

Gaskets play a role in sealing various components within the engine brake system. The Feeler Gage .015" is useful for verifying the thickness of these gaskets, ensuring that they provide the correct sealing properties without causing undue stress on mating surfaces. Accurate gasket thickness is essential for maintaining the integrity of the engine brake system and preventing leaks that could compromise performance.

Conclusion

In summary, the Cummins Feeler Gage .015" (Part #3871428) is a versatile tool that aids in the precise measurement and adjustment of various components within an engine brake kit. Its applications range from valve clearance and piston ring gap measurement to ensuring proper clearances in exhaust brake systems and turbocharger housings. Accurate measurements facilitated by this tool are fundamental to the reliable and efficient operation of the engine brake system.

SPECIFICATIONS

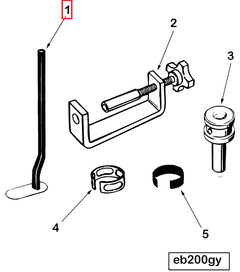

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.