This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 3888312 Corrosion Inhibitor is a specialized product designed by Cummins to protect the metal components of commercial trucks from corrosion. Its purpose is to enhance the longevity and reliability of truck engines by preventing the degradation of metal surfaces. This inhibitor plays a significant role in the maintenance and operation of commercial trucks, ensuring that engine components remain in optimal condition over time.

Basic Concepts of Corrosion Inhibitors

Corrosion inhibitors are substances that, when added to a system, reduce the rate of corrosion of metal surfaces. They function by forming a protective layer on the metal, which prevents corrosive agents from coming into contact with the metal surface. The chemical processes involved in corrosion inhibition typically include the adsorption of inhibitor molecules onto the metal surface, creating a barrier that impedes the electrochemical reactions that lead to corrosion 1.

Purpose of the 3888312 Corrosion Inhibitor

The 3888312 Corrosion Inhibitor is specifically formulated to protect the engine components and other metal parts of commercial trucks. It helps in preserving the integrity of these components by forming a protective layer that prevents corrosive agents from causing damage. This protection is vital for maintaining the performance and longevity of the truck’s engine.

Key Features

The 3888312 Corrosion Inhibitor boasts several key features that make it an effective solution for corrosion protection. Its chemical composition is designed to provide robust protection against a variety of corrosive environments. The application method is straightforward, allowing for easy integration into maintenance routines. Additionally, it is compatible with various engine types, ensuring versatility across different truck models.

Benefits

Using the 3888312 Corrosion Inhibitor offers several benefits. It contributes to extended engine life by preventing corrosion-related damage. This, in turn, leads to reduced maintenance costs, as the need for repairs and replacements decreases. Furthermore, the inhibitor helps in improving the overall performance of the truck by ensuring that engine components operate efficiently and reliably.

Application and Usage

Proper application of the 3888312 Corrosion Inhibitor is crucial for its effectiveness. Guidelines recommend specific dosages and application intervals to ensure optimal protection. These guidelines vary depending on the type of engine, allowing for tailored application that meets the specific needs of different truck models. Following these recommendations ensures that the inhibitor is effectively protecting the engine components 2.

Troubleshooting and Maintenance

In cases where corrosion issues arise, the 3888312 Corrosion Inhibitor can be part of the solution. Troubleshooting common corrosion-related problems may involve assessing the application of the inhibitor and ensuring that it is being used correctly. Regular maintenance checks can help ensure that the inhibitor continues to provide effective protection, contributing to the overall reliability of the truck’s engine.

Safety and Handling

The safe handling and storage of the 3888312 Corrosion Inhibitor are important to ensure the well-being of those using it. Necessary personal protective equipment (PPE) should be worn during application to prevent exposure. Additionally, the inhibitor should be stored in a cool, dry place, away from incompatible substances, to maintain its effectiveness and safety.

Environmental Impact

The environmental impact of using corrosion inhibitors is an important consideration. The 3888312 Corrosion Inhibitor is designed with eco-friendly aspects in mind, aiming to minimize its environmental footprint. It complies with environmental regulations, ensuring that its use does not harm the environment while providing effective corrosion protection.

Compatibility of Corrosion Inhibitor Part 3888312 with Cummins Engines

The 3888312 Corrosion Inhibitor, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is crucial for maintaining the integrity of engine components by preventing corrosion, which can lead to significant engine damage and reduced performance over time.

K-Series Engines

The K-Series engines, including K19, K38, and K50, are robust and widely used in various applications. The Corrosion Inhibitor part 3888312 is engineered to fit seamlessly within these engines, ensuring that the internal components remain protected from corrosive elements.

KTA19GC Series

The KTA19GC series, including variants like KTA19GC CM558, benefit from the use of the Corrosion Inhibitor part 3888312. This part is specifically designed to integrate with the KTA19GC engines, providing essential protection against corrosion that can occur in high-stress environments.

QSK19 Series

The QSK19 series engines, such as QSK19 CM2350 K105, QSK19 CM2350 K114, QSK19 CM2350 K144G, QSK19 CM500, QSK19 CM850 MCRS, and QSK19G, are designed for demanding applications. The Corrosion Inhibitor part 3888312 is compatible with these engines, ensuring that the internal components are safeguarded against corrosion, thereby maintaining engine performance and longevity.

QSK38 Series

The QSK38 series engines, including QSK38 CM2150 MCRS and QSK38 CM850 MCRS, are built for high-performance applications. The Corrosion Inhibitor part 3888312 is designed to fit these engines, providing critical protection against corrosion and ensuring that the engines operate efficiently and reliably.

QSK45 and QSK50 Series

The QSK45 and QSK50 series engines, such as QSK45 CM500, QSK50 CM2150 K107, QSK50 CM2150 MCRS, QSK50 CM2350 K108, and QSK50 CM500, are known for their durability and power. The Corrosion Inhibitor part 3888312 is compatible with these engines, offering essential protection against corrosion and helping to maintain the engines’ performance over time.

QSK60 Series

The QSK60 series engines, including QSK60 CM500, QSK60 CM850 MCRS, QSK60 G CM2358 K110, QSK60G, and QSK60 CM500, are designed for heavy-duty applications. The Corrosion Inhibitor part 3888312 is engineered to fit these engines, providing critical protection against corrosion and ensuring that the engines remain in optimal condition.

QSK78 Series

The QSK78 series engine, specifically QSK78 CM500, benefits from the use of the Corrosion Inhibitor part 3888312. This part is designed to integrate with the QSK78 engine, providing essential protection against corrosion and ensuring that the engine operates efficiently.

QST30 Series

The QST30 series engines, including QST30 CM2350 T101 and QST30 CM552, are built for specific applications. The Corrosion Inhibitor part 3888312 is compatible with these engines, offering essential protection against corrosion and helping to maintain the engines’ performance.

V-Series Engines

The V-Series engine, specifically V28, is designed for various applications. The Corrosion Inhibitor part 3888312 is compatible with the V28 engine, providing critical protection against corrosion and ensuring that the engine remains in optimal condition.

Role of Part 3888312 Corrosion Inhibitor in Engine Systems

In the intricate network of an engine system, the Part 3888312 Corrosion Inhibitor assumes a significant role in preserving the integrity and efficiency of various components. This inhibitor is instrumental in mitigating the adverse effects of corrosion, which can otherwise lead to system degradation and failure.

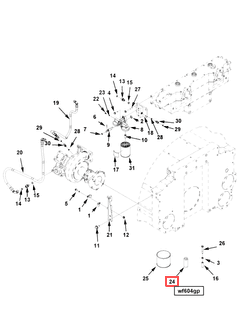

Integration with Engine Components

-

Coolant System: The corrosion inhibitor is added to the engine coolant, forming a protective layer on metal surfaces. This layer prevents the coolant from corroding the engine block, cylinder heads, and radiator, ensuring the coolant’s effectiveness in temperature regulation.

-

Engine Lubricating System: When integrated with the engine lubricating system, the inhibitor helps in maintaining the viscosity and properties of the lubricant. It prevents the formation of corrosive by-products that can damage bearings and other moving parts.

-

Water Filter and Additive: In conjunction with the water filter and water filter additive, the corrosion inhibitor enhances the filtration efficiency. It prevents corrosion within the filter housing and the additive system, ensuring clean and corrosion-free water circulation.

-

Corrosion Resistor and Mounting: The inhibitor works in tandem with corrosion resistors and their mountings. It ensures that these components remain effective in their role of resisting corrosive elements, thereby prolonging their lifespan and maintaining engine efficiency.

-

Engine Installation Kit and Hardware Kit: During the installation of an engine, the corrosion inhibitor, when included in the installation kit and hardware kit, protects all metallic components from the onset of corrosion. This is particularly important in environments where the engine is exposed to moisture and other corrosive agents.

-

On Board Spares and Package: In packages that include on-board spares, the corrosion inhibitor ensures that spare parts remain in optimal condition until they are needed. This is vital for maintaining the reliability of the engine system in the long term.

-

Priming Pump Kit and Primer: The inhibitor is also beneficial in priming pump kits and primers. It ensures that the pump components and the primer fluid are free from corrosion, facilitating smooth and efficient engine start-up and operation.

-

Accessories Mounting: For accessories mounted on the engine, the corrosion inhibitor provides a protective shield against environmental factors that could lead to corrosion. This is essential for the longevity and performance of these accessories.

Conclusion

In summary, the Part 3888312 Corrosion Inhibitor is a key component in maintaining the health and efficiency of various engine systems. Its application across different components ensures a comprehensive defense against corrosion, contributing to the overall reliability and longevity of the engine.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Giancarlo Genta and Lorenzo Morello. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.