3909373

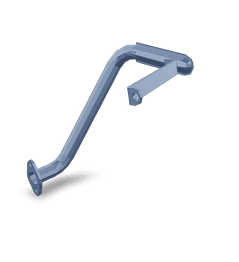

Lubricating Oil Suction Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Lubricating Oil Suction Tube, identified by Part #3909373, is a component manufactured by Cummins, a leader in the commercial truck engine industry. This tube is integral to the engine lubrication system, ensuring that oil is efficiently drawn from the oil pan and circulated throughout the engine to reduce friction, dissipate heat, and protect moving parts 1.

Basic Concepts and Functionality

Engine lubrication is fundamental to the operation and longevity of any internal combustion engine. The process involves circulating oil to critical components to minimize wear and tear. The Lubricating Oil Suction Tube plays a role in this system by facilitating the draw of oil from the oil pan to the engine’s lubrication system. It operates by connecting to the oil pan and directing oil flow to the pump, which then circulates it through the engine 2.

Purpose of the Lubricating Oil Suction Tube

The Lubricating Oil Suction Tube (Part #3909373) is designed to maintain consistent oil flow and pressure within the engine. Its role is to ensure that the oil pump receives a steady supply of oil, which is crucial for the lubrication of engine bearings, pistons, and other moving parts. By maintaining proper oil flow, it helps in reducing friction and wear, thereby contributing to the engine’s overall efficiency and durability 3.

Key Features

The Lubricating Oil Suction Tube is characterized by its robust design and the quality materials used in its construction. It is typically made from durable metals that can withstand the high temperatures and pressures within the engine compartment. The tube’s design ensures a secure fit within the engine system, minimizing the risk of leaks and ensuring efficient oil flow. Additionally, its construction may include features that enhance its resistance to corrosion and wear, further contributing to its longevity and performance.

Benefits

Incorporating the Lubricating Oil Suction Tube into an engine system offers several advantages. It contributes to improved engine performance by ensuring that all moving parts are adequately lubricated. This lubrication reduces friction and heat, which can lead to increased engine efficiency and longevity. Furthermore, by maintaining consistent oil pressure, the tube plays a role in protecting the engine from damage, thereby enhancing its reliability and overall health.

Installation and Compatibility

Proper installation of the Lubricating Oil Suction Tube is vital to ensure it functions as intended within the engine system. It should be correctly positioned and secured to prevent leaks and ensure efficient oil flow. Compatibility with various Cummins engines is a key consideration, as the tube is designed to meet the specific requirements of these engines, ensuring optimal performance and reliability.

Maintenance and Troubleshooting

Regular maintenance of the Lubricating Oil Suction Tube is recommended to ensure it continues to function optimally. This includes periodic inspections for signs of wear or damage and cleaning as necessary to remove any contaminants that could impede oil flow. Common issues may include leaks or blockages, which can often be addressed through careful inspection and cleaning. In cases where damage is detected, replacement may be necessary to maintain the integrity of the engine’s lubrication system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to excellence is evident in its wide range of products, which are designed to meet the demanding requirements of modern engines. Cummins’ dedication to quality and innovation ensures that its components, including the Lubricating Oil Suction Tube, contribute to the efficiency, reliability, and longevity of engines across various applications.

Lubricating Oil Suction Tube (Part 3909373) Compatibility with Cummins Engines

The Cummins part 3909373, a Lubricating Oil Suction Tube, is designed to fit seamlessly with several models of Cummins engines, ensuring efficient oil flow and lubrication. Here is a detailed overview of its compatibility:

Compatibility with Specific Engine Models

- 6B5.9

- B5.9 G

- B5.9 GAS PLUS CM556

- ISB CM550

- ISB5.9G CM2180

- QSB5.9 44 CM550

Grouping by Engine Series

B5.9 Series

- B5.9 G

- B5.9 GAS PLUS CM556

The 3909373 part is specifically engineered to fit the B5.9 series engines, ensuring that the oil suction tube provides the necessary lubrication for optimal engine performance. This part is crucial in maintaining the integrity of the engine’s lubrication system.

ISB Series

- ISB CM550

- ISB5.9G CM2180

For the ISB series, the 3909373 part is designed to integrate with the ISB CM550 and ISB5.9G CM2180 engines. Its precise fitment ensures that the oil suction process is uninterrupted, which is vital for the longevity and efficiency of these engines.

QSB Series

- QSB5.9 44 CM550

The QSB5.9 44 CM550 engine also benefits from the 3909373 part. This oil suction tube is crafted to meet the specific requirements of the QSB series, ensuring that the engine operates smoothly and efficiently.

By ensuring that the 3909373 part fits these various engine models, Cummins maintains a high standard of compatibility and reliability across its engine lineup. This part is an essential component in the engine’s lubrication system, providing the necessary oil flow to keep the engine running smoothly.

Role of Part 3909373 Lubricating Oil Suction Tube in Engine Systems

The lubricating oil suction tube, part 3909373, is integral to the efficient operation of engine systems by facilitating the smooth and consistent flow of oil from the oil pan to the engine’s lubrication system. This component is designed to work in harmony with the oil pan and other lubrication system components to ensure that the engine receives a steady supply of oil, which is essential for reducing friction, dissipating heat, and protecting moving parts from wear and damage.

When the engine is running, the suction tube draws oil from the oil pan, where it is stored after circulating through the engine. The oil pan acts as a reservoir, collecting used oil that has passed through the engine’s various components. The suction tube’s role is to create a reliable pathway for this oil to be pumped back into the engine’s lubrication circuit.

The design of the suction tube allows it to effectively handle the viscosity changes of oil as it warms up and cools down, ensuring a consistent flow rate. This is particularly important during cold starts when oil is thicker and more resistant to flow. The suction tube must be able to draw oil efficiently even under these conditions to prevent engine components from operating without adequate lubrication, which could lead to increased wear and potential failure.

Moreover, the suction tube is often equipped with a screen or filter at the end that dips into the oil pan. This screen captures any debris or contaminants that may be present in the oil, preventing them from entering the engine’s lubrication system and causing damage to sensitive components such as bearings and pistons.

In summary, part 3909373 lubricating oil suction tube is a key component in the engine’s lubrication system, working closely with the oil pan to ensure that the engine is consistently supplied with clean, lubricated oil. This component’s design and functionality are essential for maintaining the health and longevity of the engine by supporting the efficient operation of the lubrication system.

Conclusion

The Lubricating Oil Suction Tube, part 3909373, is a critical component in the engine lubrication system, ensuring efficient oil flow and protection of engine components. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of engine performance and longevity make it an essential part for maintaining the health and efficiency of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.