This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3917844 Ball Joint is a component designed for use in the suspension systems of commercial trucks. Its purpose is to facilitate the connection between the control arm and the steering knuckle, allowing for smooth and controlled movement of the wheels. This part plays a role in maintaining the stability and handling of the vehicle, ensuring a safe and efficient driving experience 1.

Basic Concepts of Ball Joints

A ball joint is a type of pivot joint used in the suspension systems of vehicles. It consists of a ball-shaped end that fits into a socket, allowing for multi-directional movement. This design enables the suspension to absorb shocks and maintain contact with the road surface, contributing to the overall ride comfort and vehicle control 2. In the context of a truck, the ball joint allows the wheels to move up and down while also permitting steering input, which is important for navigating turns and uneven terrain.

Operational Role of the 3917844 Ball Joint

The Cummins 3917844 Ball Joint operates within the suspension system by connecting the control arm to the steering knuckle. This connection allows the wheel to move vertically while also enabling steering rotation. The ball joint’s design ensures that the wheel can articulate smoothly, which is important for maintaining traction and stability. It works in conjunction with other suspension components, such as shocks and struts, to provide a balanced and controlled ride 3.

Key Features of the 3917844 Ball Joint

The Cummins 3917844 Ball Joint is constructed with high-quality materials to ensure durability and performance. It features a robust housing that protects the internal components from dirt and debris, which can cause wear and reduce functionality. The ball itself is made from a hard-wearing alloy, designed to resist the stresses of heavy loads and rough conditions. Additionally, the joint is lubricated for smooth operation, and it includes a dust boot to keep contaminants out.

Benefits of Using the 3917844 Ball Joint

Utilizing the Cummins 3917844 Ball Joint offers several advantages. It contributes to improved handling by ensuring that the wheels maintain proper alignment and contact with the road. The durable construction of the joint enhances the longevity of the suspension system, reducing the need for frequent replacements. Moreover, the design of the ball joint includes safety features that help prevent failure, which is important for the safe operation of commercial trucks.

Installation Process

Installing the Cummins 3917844 Ball Joint requires careful attention to detail to ensure proper function. The process involves removing the old joint, cleaning the mounting surfaces, and then pressing the new joint into place. It is important to use the correct tools to avoid damage to the joint or surrounding components. Once installed, the joint must be properly aligned to ensure that the wheel operates within the manufacturer’s specifications for camber, caster, and toe.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3917844 Ball Joint is important to ensure its continued performance. This includes periodic inspections for signs of wear, such as play in the joint or damage to the dust boot. Lubrication should be checked and replenished as needed, following the manufacturer’s guidelines. If issues are detected, such as unusual noises or vibrations, it is important to address them promptly to prevent further damage to the suspension system.

Performance Under Various Conditions

The Cummins 3917844 Ball Joint is engineered to perform reliably under a range of driving conditions. Whether navigating heavy loads, rough terrain, or varying weather conditions, the joint’s design allows it to maintain its function and contribute to the truck’s stability and control. Its ability to withstand these conditions is a testament to the quality of its construction and the materials used.

Compatibility and Applications

The Cummins 3917844 Ball Joint is designed for specific applications within the commercial truck industry. It is compatible with certain truck models and is particularly suited for use in environments where durability and performance are paramount. The joint’s design takes into account the specific demands of commercial truck operations, ensuring that it meets the needs of its intended applications.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes a variety of components that are integral to the performance and reliability of commercial vehicles, reflecting Cummins’ dedication to excellence and customer satisfaction.

Ball Joint Part 3917844 Compatibility with Cummins Engines

The Ball Joint part number 3917844, manufactured by Cummins, is designed to fit seamlessly within the mechanical systems of several Cummins engine models. This part is integral to the suspension and steering mechanisms, ensuring smooth and reliable operation.

4B3.9 and 6B5.9 Engines

The Ball Joint part 3917844 is compatible with both the 4B3.9 and 6B5.9 engines. These engines, while differing in displacement and power output, share common design elements in their suspension and steering systems. The Ball Joint’s robust construction and precise engineering make it an ideal fit for these engines, providing the necessary durability and performance required for heavy-duty applications.

6C8.3 Engine

Similarly, the Ball Joint part 3917844 is also suitable for the 6C8.3 engine. This engine, known for its efficiency and power, relies on high-quality components to maintain its operational integrity. The Ball Joint’s design ensures it can withstand the stresses and strains of continuous use, contributing to the overall reliability and longevity of the 6C8.3 engine.

Grouping of Engines

The Ball Joint part 3917844 is grouped for compatibility with the 4B3.9 and 6B5.9 engines due to their shared design principles in the suspension and steering systems. The 6C8.3 engine, while distinct in its specifications, also benefits from this Ball Joint’s design, ensuring a consistent fit and function across these models.

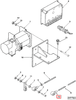

Role of Part 3917844 Ball Joint in Engine Systems

The part 3917844 Ball Joint is integral to the smooth operation and precise control of various engine systems. It facilitates the connection between the Electronic Engine Control System and the Electronic Governor Linkage, ensuring that signals and adjustments are accurately transmitted. This ball joint allows for the necessary movement and flexibility required for the governor linkage to respond to changes in engine load and speed.

When integrated with the Governor Install Kit and Governor Installation Kit, the ball joint ensures that the governor components are securely yet flexibly mounted. This setup is essential for maintaining the governor’s ability to modulate fuel delivery and engine speed in response to varying operational demands.

Additionally, the ball joint works in conjunction with the Mounting Actuator to provide a stable yet adjustable connection point. This is particularly important in systems where the actuator needs to make fine adjustments to engine parameters, such as fuel injection timing or valve timing.

Overall, the 3917844 Ball Joint plays a role in enhancing the responsiveness and reliability of the Electronic Engine Control system by ensuring that all connected components can move and adjust as needed without compromising stability or signal integrity.

Conclusion

The Cummins 3917844 Ball Joint is a critical component in the suspension systems of commercial trucks, designed to provide durability, performance, and safety. Its role in connecting the control arm to the steering knuckle ensures smooth and controlled wheel movement, contributing to the vehicle’s stability and handling. Regular maintenance and proper installation are essential to maximize the benefits of this part, ensuring a safe and efficient driving experience.

-

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Nunney, M.J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.