This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

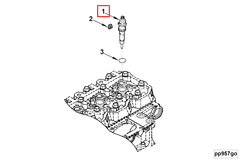

The Cummins 3935213 Injector is a component designed for use in commercial trucks, playing a significant role in the efficient operation of these vehicles. This injector is part of the fuel delivery system, ensuring that the engine receives the precise amount of fuel needed for optimal performance. Its design and functionality are essential for maintaining the balance between fuel efficiency, power output, and emissions control in heavy-duty applications 1.

Basic Concepts of Fuel Injectors

Fuel injectors are components within an engine’s fuel system responsible for delivering fuel into the combustion chamber at the precise moment and in the exact quantity required for efficient combustion. They operate under high pressure, atomizing the fuel into a fine mist that mixes with air before ignition. This process is fundamental to the combustion process, directly influencing engine performance, fuel efficiency, and emissions 2.

Purpose of the Cummins 3935213 Injector

The Cummins 3935213 Injector serves a specific function within the fuel delivery system of a truck. It is responsible for injecting fuel into the engine’s cylinders with precision, ensuring that the fuel is atomized correctly for efficient combustion. This injector contributes to the overall performance of the engine by providing the necessary fuel in a controlled manner, which is essential for maintaining engine efficiency and power output 1.

Key Features

The Cummins 3935213 Injector is characterized by several key features that enhance its performance and reliability. Its design incorporates advanced technology to ensure precise fuel delivery. The materials used in its construction are selected for durability and resistance to the high pressures and temperatures within the engine. Additionally, this injector benefits from technological advancements that improve its efficiency and longevity 3.

Benefits of Using the Cummins 3935213 Injector

Utilizing the Cummins 3935213 Injector offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered in the optimal quantity and at the precise moment. This results in more efficient combustion, which can lead to enhanced engine performance. Furthermore, the reliability of this injector helps in reducing downtime and maintenance costs, making it a valuable component for commercial truck operations 1.

Installation Process

Installing the Cummins 3935213 Injector requires careful attention to detail to ensure proper function and safety. The process involves several steps, including preparing the engine, removing the old injector (if applicable), installing the new injector, and performing a final check to ensure everything is secure and functioning correctly. Specific tools may be required, and it is important to follow manufacturer guidelines to avoid damage to the injector or engine 1.

Maintenance Tips

To ensure the Cummins 3935213 Injector operates at peak efficiency, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning to remove any deposits that may affect performance, and ensuring all connections are secure. Adhering to a maintenance schedule can help prevent issues and extend the lifespan of the injector 3.

Troubleshooting Common Issues

Common problems with the Cummins 3935213 Injector may include poor fuel atomization, leaks, or irregular engine performance. Troubleshooting these issues involves identifying the symptoms, checking for physical damage or wear, and ensuring that the injector is correctly installed and functioning as intended. Addressing these problems promptly can help maintain engine performance and efficiency 1.

Performance Enhancements

For those looking to further improve engine performance, there are potential modifications or upgrades that can be made to the Cummins 3935213 Injector. These may include adjustments to the fuel delivery system, upgrades to the injector itself, or the addition of performance-enhancing components. Careful consideration and professional advice are recommended when pursuing these enhancements to ensure compatibility and safety 3.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability and performance in the automotive industry. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the field 1.

Cummins Injector 3935213 Compatibility

The Cummins Injector part number 3935213 is a critical component designed to fit seamlessly within various Cummins engine models. This injector is engineered to deliver precise fuel metering, ensuring optimal combustion efficiency and performance.

Engine Compatibility

-

4B3.9 Series: The injector is specifically designed to integrate with the 4B3.9 engine series. This compatibility ensures that the injector can handle the unique demands of this engine, providing reliable and consistent fuel delivery.

-

Other Cummins Engines: While the primary focus is on the 4B3.9 series, the injector 3935213 may also be compatible with other Cummins engines. It is essential to verify the specific engine model and configuration to ensure proper fitment and performance.

Installation and Performance

When installed in the 4B3.9 engine, the injector 3935213 plays a pivotal role in the engine’s operation. It is designed to withstand the high pressures and temperatures typical of diesel engines, ensuring durability and longevity. The injector’s precision in fuel delivery helps maintain engine efficiency, reduce emissions, and enhance overall performance.

Application Considerations

For optimal performance, it is crucial to ensure that the injector is correctly matched with the engine’s specifications. Regular maintenance and inspection of the injector are recommended to prevent issues such as clogging or wear, which can affect engine performance and fuel efficiency.

Role of Part 3935213 Injector in Engine Systems

The injector, specifically part 3935213, is a pivotal component in the orchestration of engine systems, significantly influencing both the efficiency and performance of the engine. This injector is engineered to deliver precise amounts of fuel into the combustion chamber at optimal times, ensuring a balanced air-fuel mixture.

In the context of engine performance, the injector’s role extends beyond mere fuel delivery. It interacts with the engine control unit (ECU) to adapt fuel injection timing and quantity based on real-time data from various sensors. This dynamic interaction allows for adjustments that enhance engine responsiveness, power output, and fuel efficiency.

Moreover, the injector’s design and operation are integral to the reduction of emissions. By ensuring a consistent and fine fuel spray, it promotes complete combustion, minimizing the release of unburnt hydrocarbons and other pollutants. This not only aids in meeting environmental regulations but also contributes to the longevity of the engine by reducing carbon deposits.

Conclusion

In summary, the Cummins 3935213 Injector is a sophisticated component that plays a significant role in optimizing engine performance, efficiency, and environmental compliance through its precise fuel delivery and interaction with the engine’s electronic control systems 123.

-

Martynn Randall, Haynes Manual on Diesel Engines, Haynes Publishing, 2015.

↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ ↩ -

Michael Hilgers, Entire Vehicle: Second Edition, Springer Nature, 2023.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.