This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

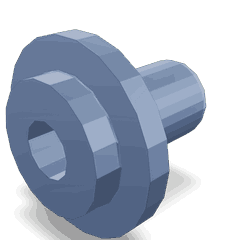

The Cummins 3935228 Idler Shaft is a component designed for use in heavy-duty truck engines. It serves a specific function within the engine’s timing system, contributing to the overall efficiency and reliability of the vehicle. Understanding its role and significance can provide valuable insights into the complexities of heavy-duty truck mechanics.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component used in various systems to guide or redirect the motion of other parts. In the context of a truck’s engine, it typically assists in maintaining the correct tension and alignment of timing belts or chains. This ensures that the engine’s valves open and close at the precise moments required for optimal performance 1.

Purpose of the Cummins 3935228 Idler Shaft

This Cummins part plays a role in the truck’s engine by supporting the timing system. It helps maintain the proper operation of the valves by ensuring that the timing belt or chain remains correctly tensioned and aligned. This is vital for the synchronization of the engine’s components, which directly impacts the engine’s performance and durability 2.

Key Features

The Cummins 3935228 Idler Shaft is characterized by its robust design and the quality materials used in its construction. It is engineered to withstand the high stresses and temperatures encountered in heavy-duty truck engines. Unique attributes such as precision machining and durable coatings enhance its performance and longevity, making it a reliable component in demanding applications 3.

Benefits of Using the Cummins 3935228 Idler Shaft

Incorporating this part into a truck’s engine can lead to several advantages. These include improved engine performance due to precise timing, increased reliability from its durable construction, and enhanced longevity as a result of its high-quality materials and design. These factors contribute to the overall efficiency and effectiveness of the engine.

Installation and Compatibility

Proper installation of the Cummins 3935228 Idler Shaft is important for ensuring optimal performance. This involves following manufacturer guidelines to prepare the engine compartment, correctly positioning the idler shaft, and securing it in place. Attention to detail during installation helps prevent issues that could affect the engine’s operation.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to prolong the life of the Cummins 3935228 Idler Shaft. This includes periodic inspections for wear or damage, ensuring proper lubrication, and addressing any signs of malfunction promptly. Common issues may involve noise from the timing system or irregularities in engine performance, which can often be traced back to the idler shaft.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its wide range of engines and components. With a history of innovation and quality, Cummins has built a reputation for producing reliable and high-performance parts. The company’s product range includes engines, filtration systems, and aftermarket parts, catering to various industries and applications.

Idler Shaft 3935228 Compatibility with Cummins Engines

The Idler Shaft part number 3935228, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for maintaining the balance and smooth operation of the engine’s components. Below is a detailed description of the engines with which this idler shaft is compatible.

ISB Series Engines

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISBE CM2150

- ISBE4 CM850

The Idler Shaft 3935228 is specifically engineered to fit within the ISB series engines, ensuring optimal performance and longevity. These engines are known for their reliability and efficiency, making them a popular choice in various applications.

QSB Series Engines

- QSB4.5 CM2250 EC

- QSB4.5 CM850(CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850(CM2850)

- QSB7 CM2880 B117

The Idler Shaft 3935228 is also compatible with the QSB series engines. These engines are designed for heavy-duty applications and are known for their durability and power. The idler shaft plays a critical role in these engines by reducing friction and wear, contributing to the overall efficiency and lifespan of the engine.

ISL Series Engines

- ISL G CM2180

- ISL9 CM2150 SN

The Idler Shaft 3935228 fits seamlessly with the ISL series engines, which are typically used in on-highway applications. These engines are engineered for high performance and fuel efficiency, making them suitable for various commercial and industrial uses.

QSF Series Engines

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

- QSF3.8 CM2350 F107

The Idler Shaft 3935228 is also compatible with the QSF series engines, which are often used in specialized applications such as marine and construction equipment. These engines are built to withstand demanding conditions, and the idler shaft is essential for maintaining the smooth operation of the engine’s components.

By ensuring that the Idler Shaft 3935228 is correctly installed in any of the aforementioned engines, users can expect improved engine performance, reduced maintenance needs, and enhanced reliability.

Role of Part 3935228 Idler Shaft in Engine Systems

The 3935228 Idler Shaft is an integral component in various engine systems, facilitating the smooth operation of multiple mechanical parts. Its primary function is to maintain tension in the drive belt system, ensuring efficient power transmission from the engine to auxiliary components.

Interaction with the Compressor and Refrigerant System

In systems involving a refrigerant compressor, the idler shaft plays a significant role. It helps in maintaining the correct tension on the drive belt that connects the engine to the compressor. This ensures that the compressor operates efficiently, allowing for optimal compression of the refrigerant. Proper tension is vital for the consistent performance of the refrigerant system, preventing issues such as slippage or excessive wear on the belt.

Connection to the Water Pump and Water Inlet

The idler shaft is also essential in systems where a water pump is driven by a belt. It ensures that the belt remains taut, allowing the water pump to draw water from the inlet and circulate it through the engine for cooling. This is particularly important in preventing overheating, as consistent water flow is necessary for effective heat dissipation.

Coordination with Idler Pulley and Idler Pulley Kit

The idler shaft often works in conjunction with an idler pulley or an idler pulley kit. These components help in adjusting the tension of the drive belt. The idler shaft’s position can be altered to increase or decrease tension, accommodating variations in belt wear or changes in the driven components’ requirements. This dynamic adjustment capability is key to maintaining optimal belt tension throughout the engine’s operational life.

Mounting and Location Considerations

The mounting location of the idler shaft is strategically chosen to provide the best possible tension and alignment for the drive belt. Its placement ensures that the belt runs true and minimizes the risk of misalignment, which can lead to increased wear and potential failure of the belt or other components.

Conclusion

In summary, the 3935228 Idler Shaft is a vital component in ensuring the reliable and efficient operation of various engine systems. Its role in maintaining belt tension is fundamental to the performance of connected components such as the compressor, water pump, and idler pulleys. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this part in heavy-duty truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.