This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

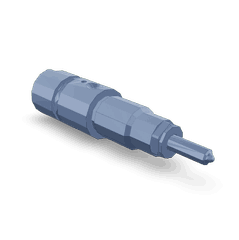

The Cummins 3944200 Injector is a component designed for use in commercial trucks, contributing to the efficient operation of these vehicles. This injector is part of Cummins Inc.’s lineup of diesel engine components, known for their reliability and performance. Its purpose is to deliver fuel into the engine’s combustion chamber with precision, enhancing the overall efficiency and power output of the truck.

Basic Concepts of Fuel Injectors

Fuel injectors are devices that deliver fuel into an engine’s combustion chamber. They operate by atomizing fuel into a fine mist, which mixes with air before combustion. This process is vital for the efficient burning of fuel, which in turn powers the engine. The precision with which fuel is delivered affects the engine’s performance, fuel efficiency, and emissions 1.

Purpose of the Cummins 3944200 Injector

The Cummins 3944200 Injector is designed to enhance the fuel delivery process in diesel engines. It ensures that fuel is injected into the combustion chamber at the optimal time and in the correct amount, which is crucial for efficient combustion. This injector contributes to the engine’s performance by improving fuel atomization, which leads to more complete combustion and, consequently, better engine efficiency and power output.

Key Features

The Cummins 3944200 Injector boasts several features that enhance its performance. Its design incorporates advanced materials and precision engineering to ensure durability and efficiency. The injector is equipped with electronic controls that allow for precise fuel delivery, adapting to various engine conditions for optimal performance. Additionally, its construction is robust, designed to withstand the high pressures and temperatures within a diesel engine.

Benefits of Using the Cummins 3944200 Injector

Utilizing the Cummins 3944200 Injector offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is used more effectively during combustion. This injector also enhances engine performance, providing smoother operation and increased power output. Furthermore, its reliable design ensures consistent performance over time, reducing the likelihood of engine issues related to fuel delivery.

Installation and Compatibility

Proper installation of the Cummins 3944200 Injector is crucial for its effective operation. It is designed to be compatible with specific Cummins engine models, ensuring that it meets the engine’s requirements for fuel delivery. Installation procedures should follow manufacturer guidelines to ensure that the injector is securely fitted and functions as intended.

Maintenance and Troubleshooting

Maintaining the Cummins 3944200 Injector is key to ensuring its longevity and performance. Regular inspections and cleaning are recommended to prevent buildup that could affect fuel delivery. Troubleshooting common issues, such as irregular fuel spray or engine performance problems, may involve checking the injector’s electrical connections, fuel lines, and the injector itself for signs of wear or damage.

Performance Enhancements

The Cummins 3944200 Injector contributes to overall engine performance by improving fuel atomization and combustion efficiency. This leads to increased power output and torque, making the engine more responsive and efficient. Additionally, by ensuring more complete combustion, this injector helps in reducing emissions, aligning with environmental standards.

Technological Innovations

The Cummins 3944200 Injector incorporates several technological innovations. Precision engineering and the use of advanced materials ensure its durability and efficiency. Electronic controls allow for precise fuel delivery, adapting to engine conditions for optimal performance. These innovations contribute to the injector’s reliability and effectiveness in enhancing engine performance.

Environmental Impact

The use of the Cummins 3944200 Injector has positive environmental implications. By improving fuel efficiency and ensuring more complete combustion, it helps in reducing fuel consumption and emissions. This contributes to lower greenhouse gas emissions and a smaller environmental footprint, aligning with global efforts to reduce the impact of transportation on the environment.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to sustainability, Cummins has established itself as a leader in the diesel engine industry. The company’s mission is to create value for customers and other stakeholders by delivering innovative, quality products and services that meet or exceed their expectations.

Compatibility of Cummins Injector 3944200

The Cummins injector part number 3944200 is a critical component for several engine models, ensuring efficient fuel delivery and combustion. This injector is compatible with the following engines:

B4.5 RGT

The B4.5 RGT engine benefits from the precise fuel injection provided by the 3944200 injector, enhancing performance and reliability in various applications.

ISB CM550

The ISB CM550 engine utilizes the 3944200 injector to deliver fuel with high accuracy, contributing to the engine’s overall efficiency and power output.

QSB5.9 44 CM550

Similar to the ISB CM550, the QSB5.9 44 CM550 engine also relies on the 3944200 injector for optimal fuel injection, ensuring consistent performance and durability.

These engines, while distinct in their applications and specifications, share a common requirement for the 3944200 injector to maintain their operational integrity and efficiency.

Role of Part 3944200 Injector in Engine Systems

The part 3944200 injector is a pivotal component in the orchestration of engine performance. Its primary function is to deliver a precise amount of fuel into the combustion chamber at the exact moment required for optimal engine operation. This precision is essential for maintaining the delicate balance between fuel efficiency, power output, and emissions control.

Integration with Engine Components

-

Fuel Rail: The injector is mounted on the fuel rail, which distributes pressurized fuel to each injector. The consistent pressure supplied by the fuel rail ensures that the injector can atomize the fuel effectively, promoting a fine mist that mixes well with air for complete combustion.

-

Engine Control Unit (ECU): The ECU monitors various engine parameters such as engine speed, load, and temperature. It sends signals to the injector to open and close at specific intervals, ensuring that the fuel delivery is synchronized with the engine’s operational demands.

-

Combustion Chamber: Once the injector releases fuel into the combustion chamber, it mixes with the air that has been drawn in during the intake stroke. The timing and quantity of fuel injection are critical for achieving the desired air-fuel ratio, which directly influences engine performance and emissions.

-

Exhaust System: Proper fuel injection leads to more efficient combustion, which in turn reduces the amount of unburnt fuel and harmful emissions expelled through the exhaust system. This not only enhances performance but also ensures compliance with environmental regulations.

-

Turbocharger (if equipped): In turbocharged engines, the injector’s role becomes even more significant. The increased air pressure from the turbocharger requires a corresponding increase in fuel delivery to maintain the optimal air-fuel ratio. The injector must be capable of handling higher fuel pressures and flow rates to meet these demands.

-

Intercooler: In engines equipped with an intercooler, the cooled air density increases, allowing for more fuel to be injected without risking detonation. The injector must be precisely calibrated to take advantage of the denser air charge provided by the intercooler.

-

Oxygen Sensor: Feedback from the oxygen sensor helps the ECU fine-tune the fuel injection process. The sensor measures the oxygen content in the exhaust gases, providing data that the ECU uses to adjust the injector’s operation for optimal performance and efficiency.

-

Throttle Body: The position of the throttle body affects the amount of air entering the engine. The injector must adapt its fuel delivery in real-time to match the varying air intake, ensuring a consistent air-fuel ratio under all driving conditions.

Conclusion

In summary, the part 3944200 injector is a sophisticated component that interacts with multiple engine systems to ensure efficient and effective fuel delivery. Its role is integral to the overall performance, efficiency, and environmental compliance of the engine.

-

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.